Wireless measurement method for capacitor

A wireless measurement and capacitor technology, which is applied to the parts of electrical measuring instruments, measuring electricity, measuring devices, etc. Improve test efficiency and facilitate management and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

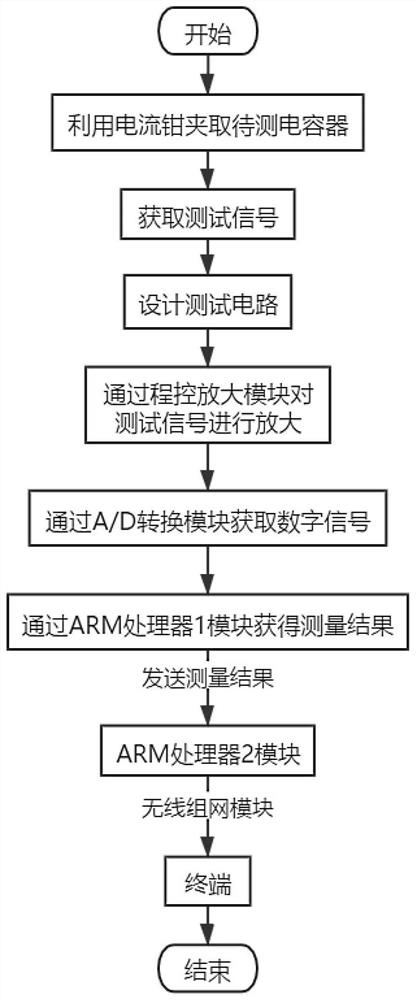

[0027] refer to Figure 1 ~ Figure 2 , which is the first embodiment of the present invention, this embodiment provides a wireless measurement method for capacitors, including:

[0028] S1: Use the current clamp to clamp the capacitor under test to obtain the test signal.

[0029] Preferably, in order to reduce the workload of the measurement process, the method adopts the current clamp method for detection; the current clamp can detect the current flowing through a single capacitor, and calculate the voltage by using the voltage detected on the capacitor and the current sampled by the current clamp. capacity.

[0030] S2: Design the test circuit.

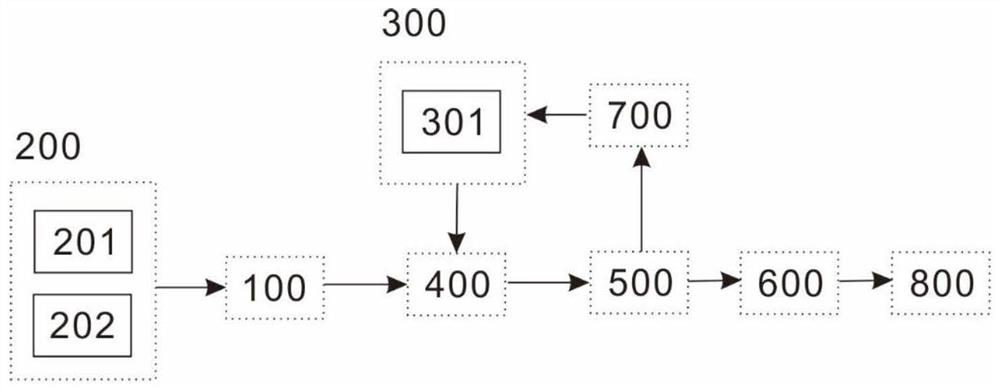

[0031] refer to figure 2 , the test circuit includes a programmable amplifier module 100, a signal input protection module 200, a voltage divider module 300, an A / D conversion module 400, an ARM processor 1 module 500, an ARM processor 2 module 600, a power amplifier module 700 and a wireless networking module 800 .

[0032] ...

Embodiment 2

[0050] The technical effect adopted in this method is verified and explained. This embodiment chooses the traditional technical solution and adopts this method to conduct a comparative test, and compares the test results by means of scientific demonstration to verify the real effect of this method.

[0051] When testing a single capacitor of the compensation capacitor bank, the traditional technical solution needs to remove the capacitor leads and test one by one. The test data needs to be recorded by hand and cannot be collected automatically.

[0052] In order to verify that this method does not need to remove the capacitor lead when testing the single capacitance of the compensation capacitor group compared with the traditional technical solution, it can complete the single and total capacitance test and realize wireless automatic collection of test data.

[0053] In this embodiment, the traditional technical solution and this method will be used to test the capacitance of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com