Engine camshaft standard working condition testing platform

A test bench and camshaft technology, which is used in engine testing, mechanical component testing, and machine/structural component testing, etc., can solve problems such as large differences in engine camshaft test benches, real damage to simulated materials, and difficulty in life. Achieve the effect of ensuring stability and continuity, reducing noise, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

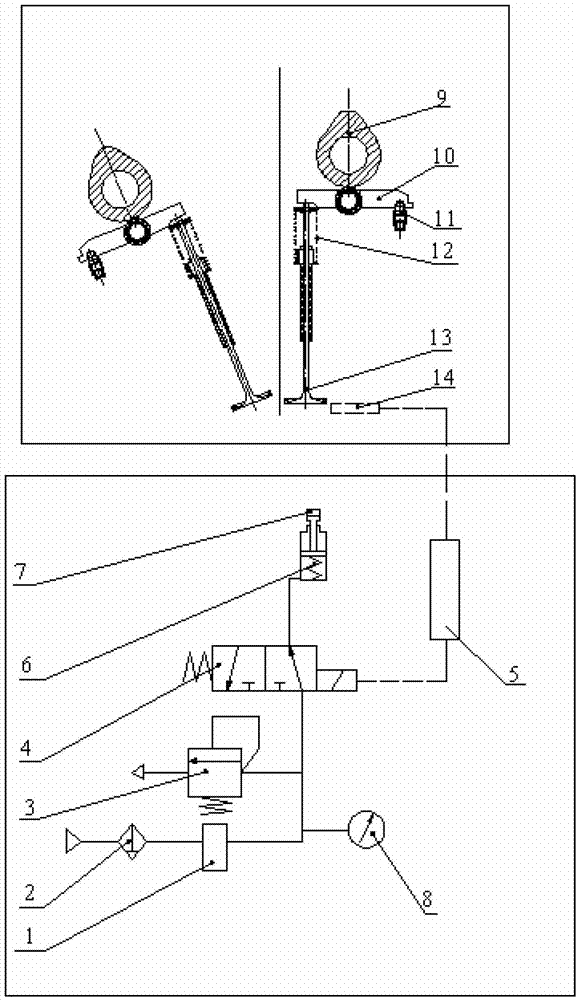

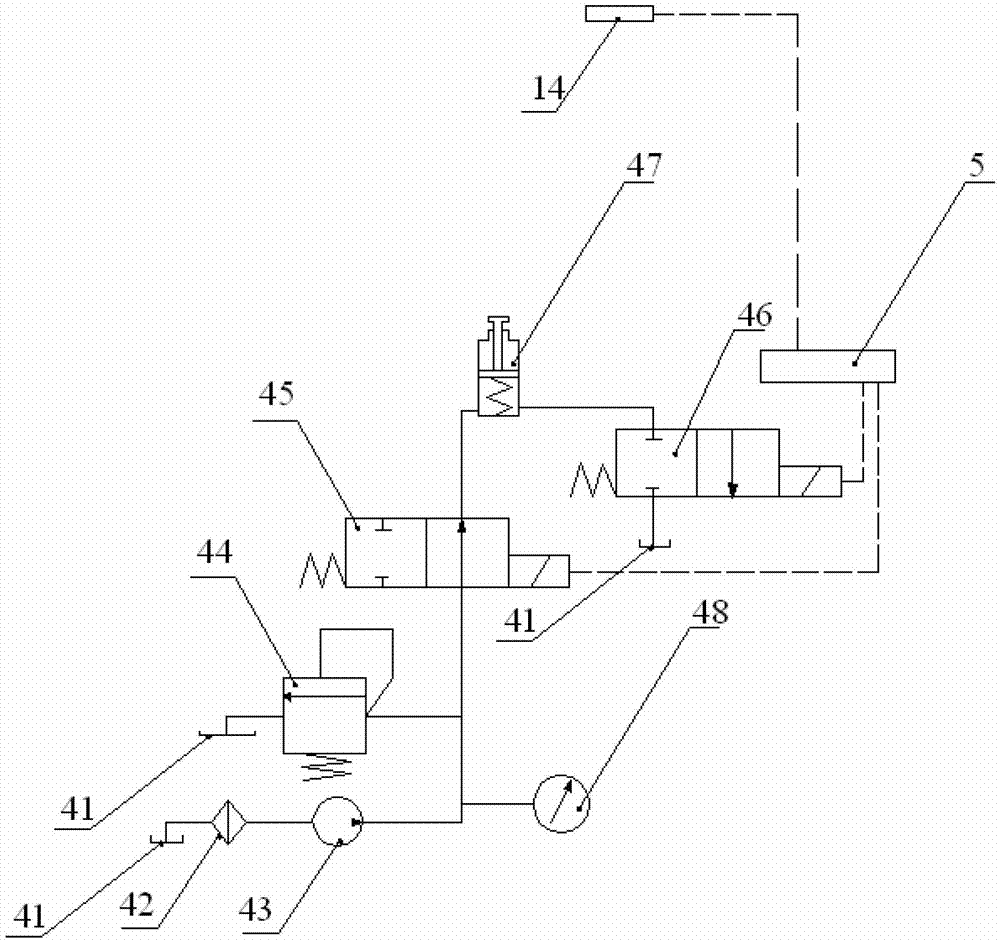

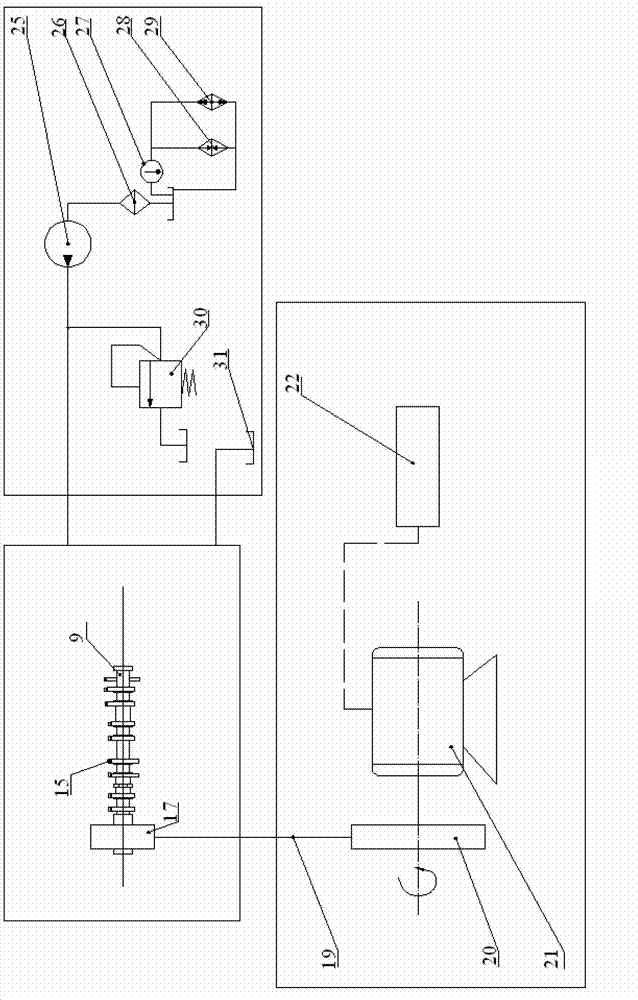

[0048] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0049] The invention belongs to a cold-state engine test stand, which simulates the operating conditions of the engine without starting the engine, tests the performance of a camshaft and a cam, reduces energy waste, reduces test costs, and improves test reliability.

[0050] The present invention focuses on the thermal environment of each main working interface of the camshaft mechanism to test and simulate, using the lubricating oil at the actual working temperature, the valve end has an active load, more truly reflects the working conditions of the engine, and effectively detects the performance of the camshaft, for testing Camshaft life and reliability provide the necessary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com