Total organic carbon detection method during compound salvia miltiorrhiza dripping pill production process

A detection method and production process technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult to meet the requirements of cleaning verification, unsatisfactory sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] Example 1 Measure the TOC value of the cleaning verification sampling point, the stirring blade of the No. 3 chemical material tank on the No. 2 line of the compound Danshen dripping pill production line.

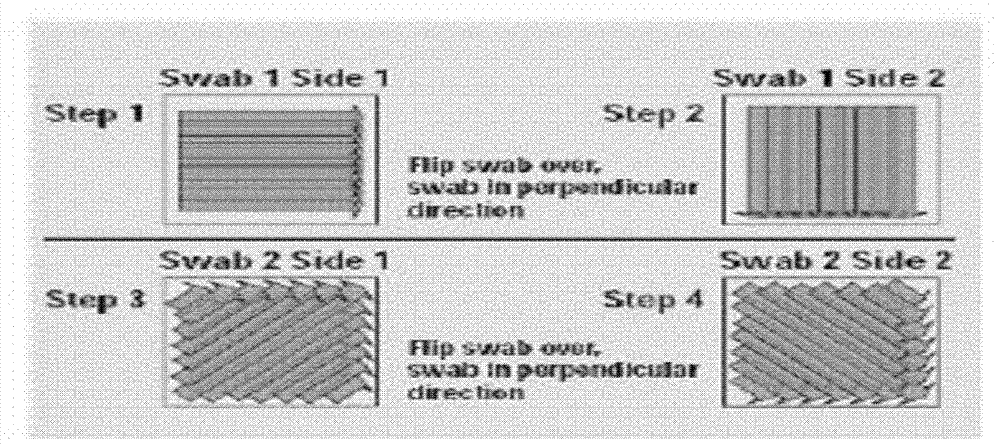

[0165] Randomly select an area of 10cm*10cm on the stirring blade of No. 3 chemical material tank on Line 2, take a wiping cotton swab, moisten it with ultrapure water, and control it to dry at the mouth of the sampling bottle until no water drips, and then wipe it horizontally with the cotton swab Sampling point, turn the cotton swab over, wipe the sampling point vertically, turn the cotton swab over, wipe the sampling point from the bottom left to the top right, turn the cotton swab over, and wipe the sampling point from the top left to the bottom right. After sampling, break off the sampling cotton swab in the sampling bottle (do not touch the cotton swab head with your hands during the process). As attached in the manual figure 1 shown. Add 40ml of ultrapure ...

Embodiment 2

[0166] Example 2 Measuring the TOC value of the cleaning verification sampling point of the final rinse water of the No. 4 chemical material tank of the No. 1 line of the compound Danshen dripping pill production line

[0167] After cleaning the No. 4 chemical material tank of Line 1 according to the cleaning procedures, add a certain amount of purified water to it, rinse the entire chemical material tank, use a sampling bottle to collect about 40ml of final rinse water, and observe whether there are large particles in the sample And the color of the sample (if there are larger particles, you need to wait for the particles to settle, then take 30ml of the supernatant to another sampling bottle for testing to prevent the particles from clogging the sampling tube. If the color of the sample is darker, you need to dilute After that, the sample can be tested, in case the amount of organic carbon is too high and exceeds the detection range of the instrument.), insert the mouth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com