Ring-shaped microstructure fiber

A micro-structured fiber and ring technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of single-mode transmission, poor loss attenuation, large loss of high-order mode, etc., to reduce binding loss, reduce bending loss, Simple and symmetrical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

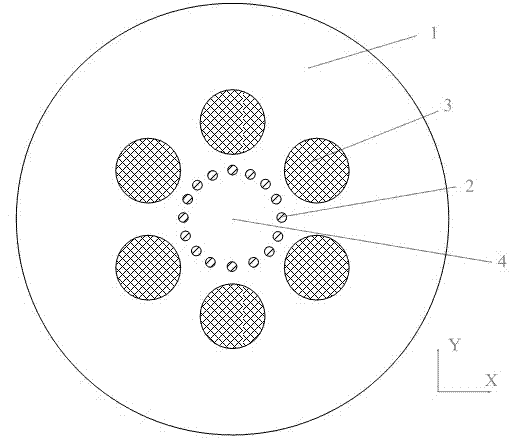

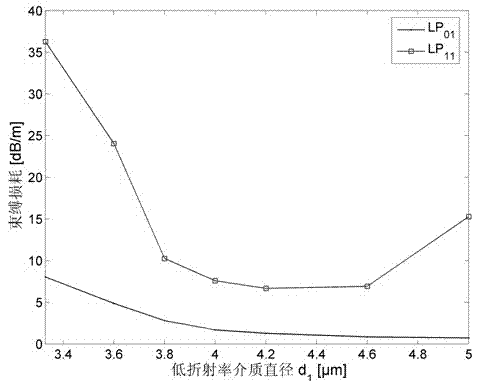

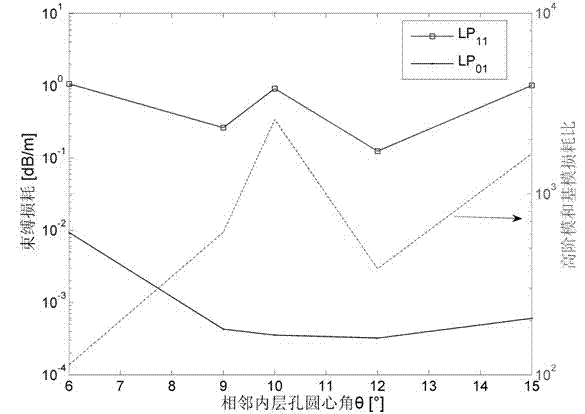

[0029] The cross-sectional structure of the optical fiber is as figure 1 shown. The matrix material is pure quartz, and the hole material is doped quartz material. The diameter d of the first medium column 2 1 =5μm, distance L from fiber center 1 =30μm, number N 1 =20. The diameter d of the second medium column 3 2 =42μm, distance L from fiber center 2 =60μm, number N 2 =6. The low refractive index dielectric pillars have a refractive index 0.004 lower than the matrix material. When the transmission wavelength is 1064 nm, the fundamental mode field area in straight fiber can reach 1498 μm 2 , when the bending radius is 50 cm, the mode field area of the fundamental mode is 1384 μm 2 . The bending loss of the optical fiber is 0.095dB / m when the bending radius is 50cm. When the fiber is straight, its fundamental mode leakage loss is less than 0.002dB / m, and its high-order mode loss is greater than 1.11dB / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap