Patents

Literature

36results about How to "Achieve the purpose of transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

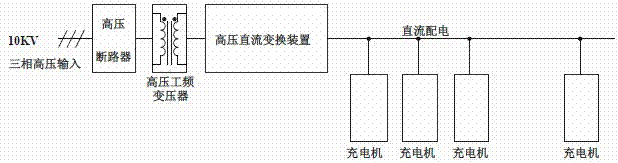

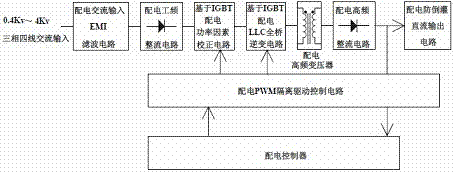

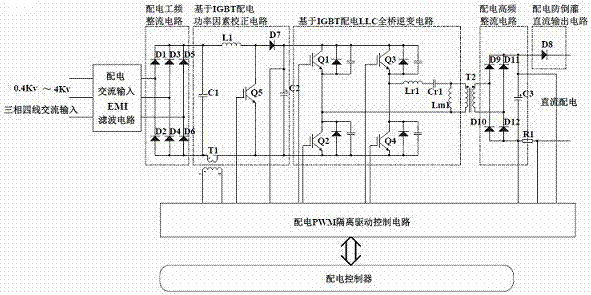

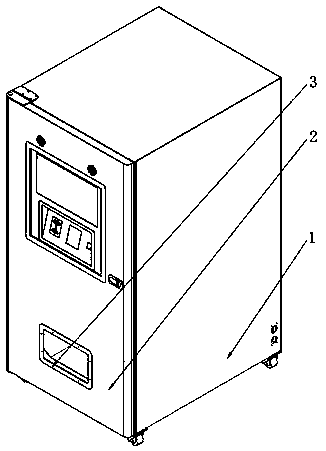

High withstand voltage IGBT DC power distribution based electric vehicle charging station

InactiveCN107069891ASolve the rectificationAvoid correctionCharging stationsMobile unit charging stationsTransformerPower factor

The invention discloses a high withstand voltage IGBT DC power distribution based electric vehicle charging station. The high withstand voltage IGBT DC power distribution based electric vehicle charging station comprises a high-voltage circuit breaker, a high-voltage power frequency transformer, a high-voltage DC conversion device and a charger. A three-phase high-voltage input voltage is connected with the high-voltage power frequency transformer through the high-voltage circuit breaker; the output end of the high-voltage power frequency transformer is connected with the high-voltage DC conversion device; and the high-voltage DC conversion device converts a three-phase high-voltage input AC power into a DC power and then supplies to DC power to the charger. By adoption of the high withstand voltage IGBT, the high-voltage DC conversion device realizes power factor correction, LLC full bridge inversion and a DC power distribution scheme of converting the three-phase high-voltage input AC power into the DC power and then supplying the DC power to the charger; and without power factor correction, the design of the DC charging module is simplified, the power density of the DC charging module is improved, the reliability of the charger is improved and the cost of the charger is reduced. In addition, the high withstand voltage IGBT DC power distribution based electric vehicle charging station increases the device IP protection level, improves the working reliability of the device in an outdoor malicious environment and prolongs the service life of the device.

Owner:GUANGDONG THOUSANDS OF CITIES & CHARGING STATIONS E VEHICLES OPERATING CO LTD

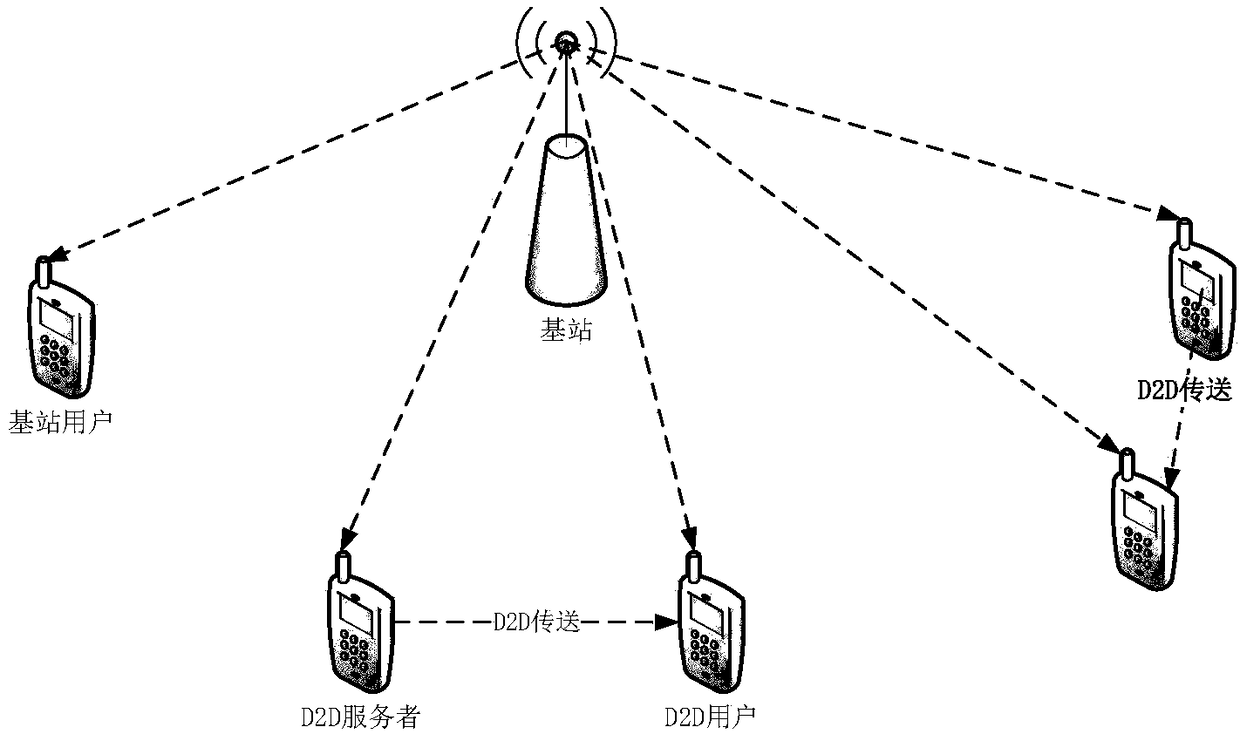

Base station and D2S common cache method oriented to wireless heterogeneous network

ActiveCN108541025AReduce loadReduce load pressureNetwork traffic/resource managementMachine-to-machine/machine-type communication serviceTraffic capacityHeterogeneous network

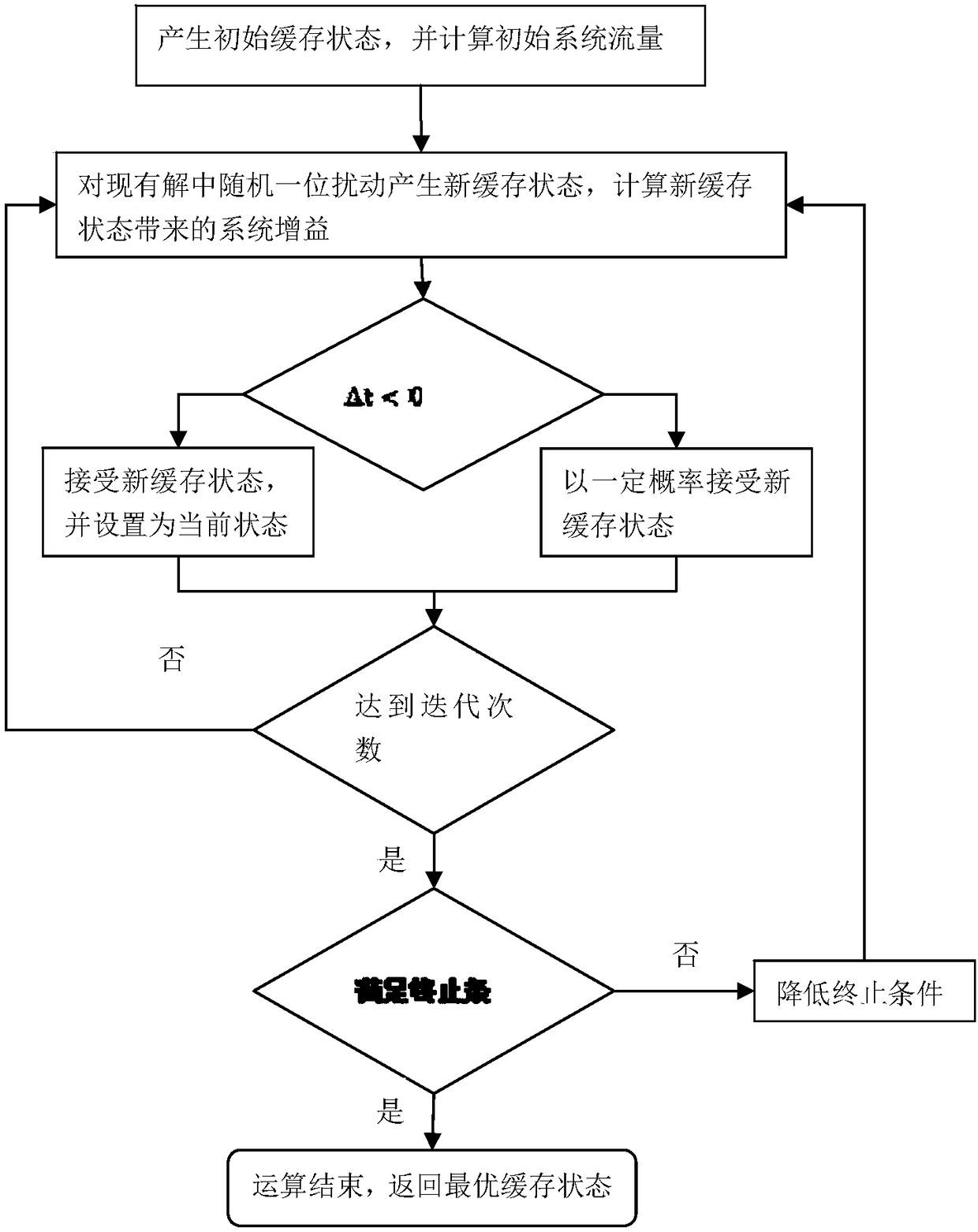

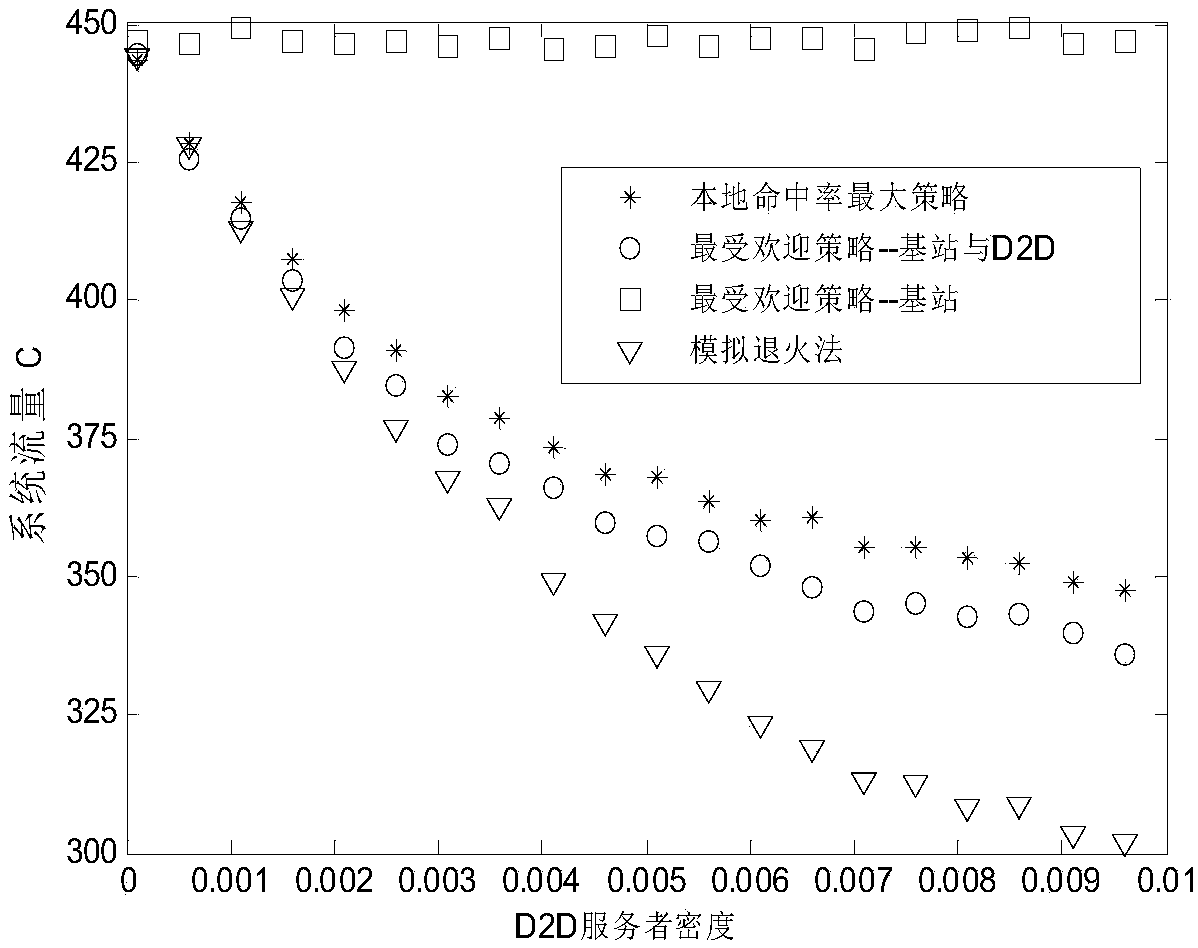

The invention discloses a base station and D2S common cache method oriented to a wireless heterogeneous network. The method comprises the following steps: firstly establishing a system model for the common work of D2D cache and base station cache, and dividing users into two types: a D2D user and a base station user; preferentially acquiring a file from a neighbor D2D servant when the D2D user requests the file in a system, requesting the file from the base station if the corresponding file is unfound, wherein the base user directly requests the file from the base station; and turning to a core network to request for the file uncached by each of the base station and the D2D servant. For reducing the system traffic of a common work scene of the base station and the D2D, a cache content deciding method based on a simulated annealing method is designed. A simulation result shows that the system traffic can be effectively reduced through the method in comparison with the existing cache method, the base station load and the backhaul load are lowered, and the cache hit rate is improved.

Owner:XI AN JIAOTONG UNIV

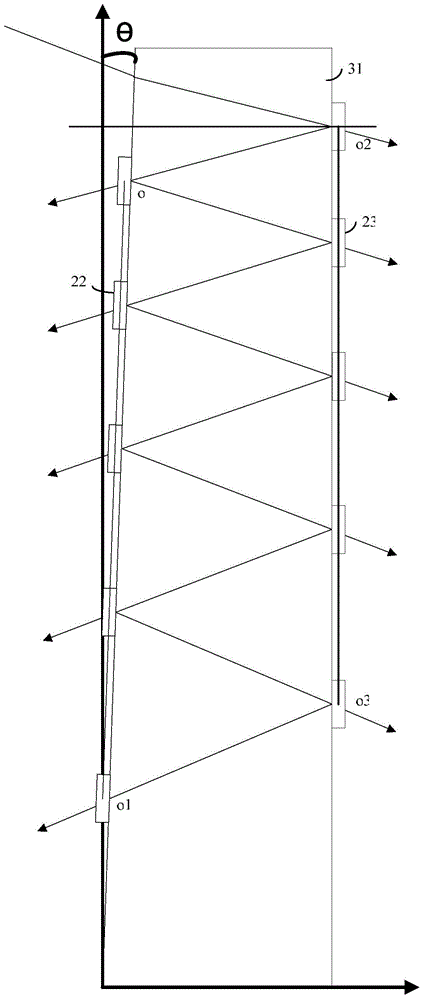

Multiplexing/demultiplexing optical equipment and method for realizing optical path multiplexing/demultiplexing

ActiveCN103605188AImprove practicalityAvoid interferenceOptical light guidesMultiplexingWavelength filter

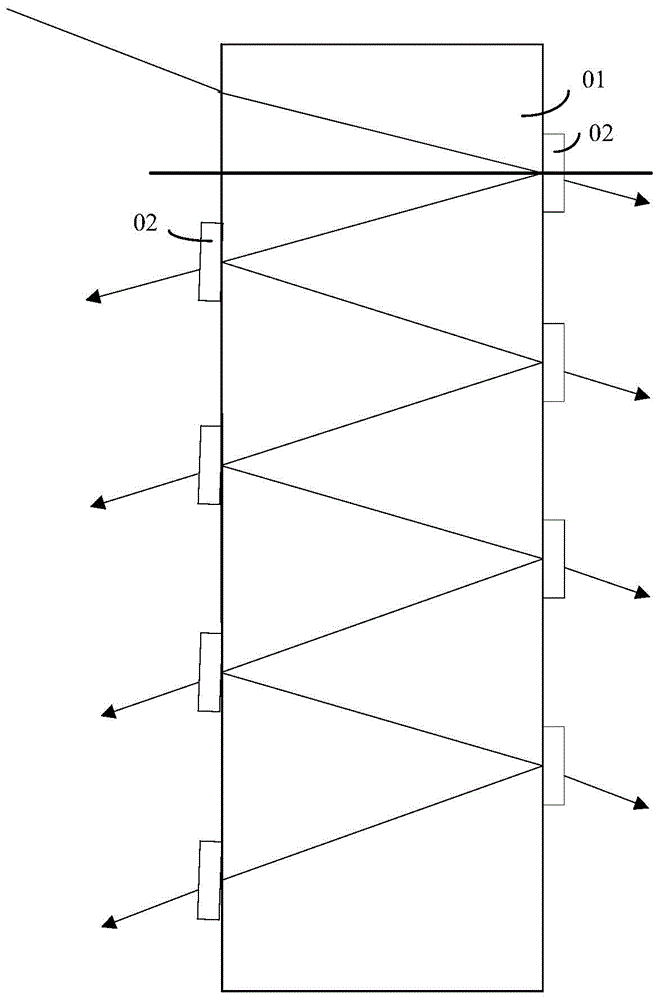

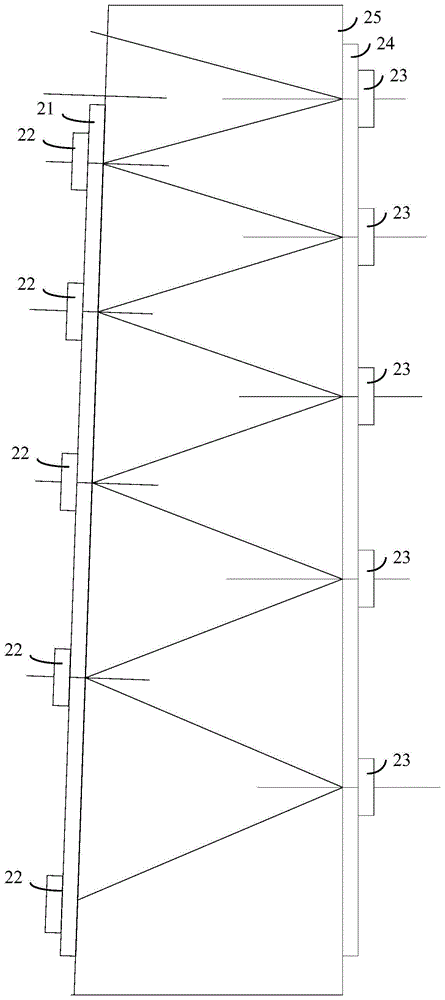

The invention discloses multiplexing / demultiplexing optical equipment and a method for realizing optical path multiplexing / demultiplexing. According to the multiplexing / demultiplexing optical equipment, a first wedge-shaped optical block is fixed on a first side surface of a dielectric body, a second wedge-shaped optical block is fixed on a second side surface opposite to the first side surface on the dielectric body, and the first side surface and the second side surface form a preset angle; an incidence port is formed in the upper part of the side surface of the first wedge-shaped optical block; one or more parallel selective-wavelength filters are fixed below the incidence port along the vertical direction of the first wedge-shaped optical block, and the connection line of the center of each selective-wavelength filter is a straight line and is parallel to the first side surface; one or more parallel selective-wavelength filters are fixed along the vertical direction of the second wedge-shaped optical block, and the connection line of the center of each selective-wavelength filter is a straight line and is parallel to the second side surface. By applying the multiplexing / demultiplexing optical equipment and the method disclosed by the invention, the practicability of the multiplexing / demultiplexing optical equipment can be improved.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

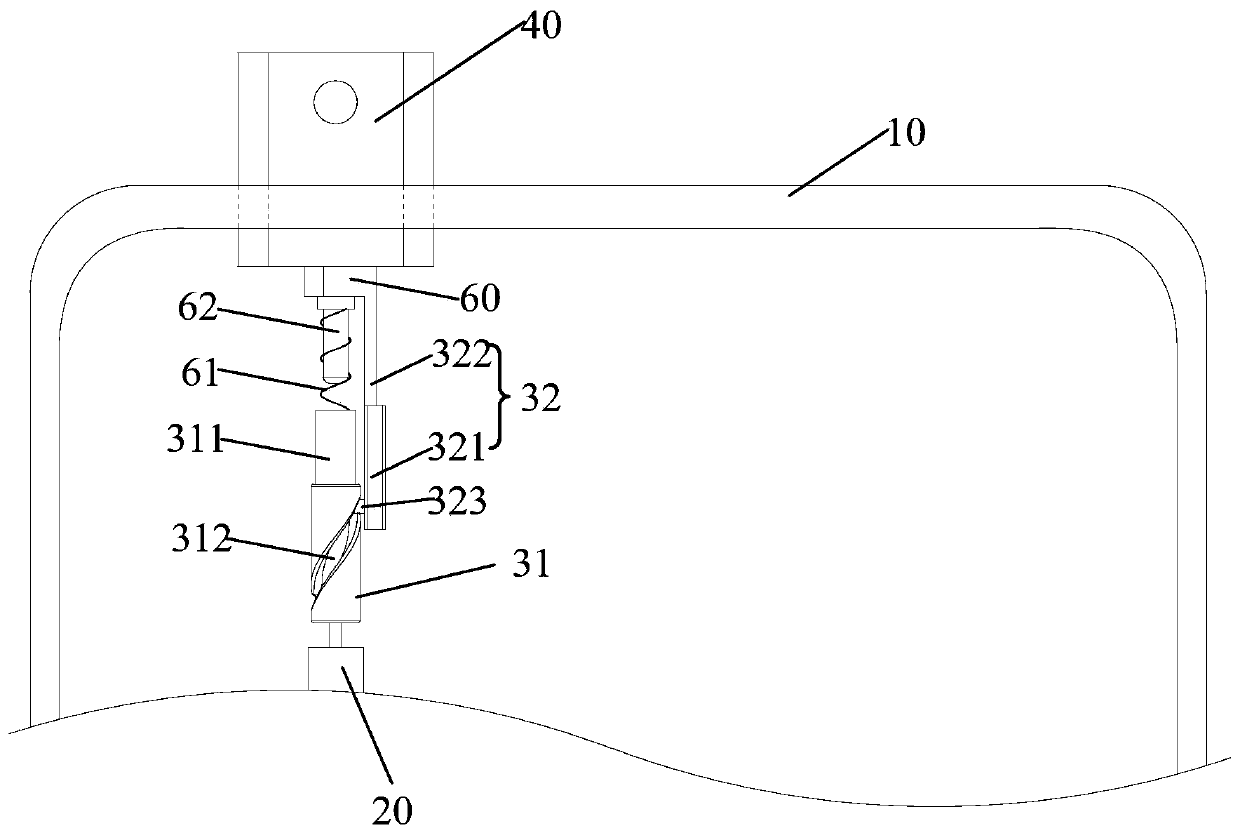

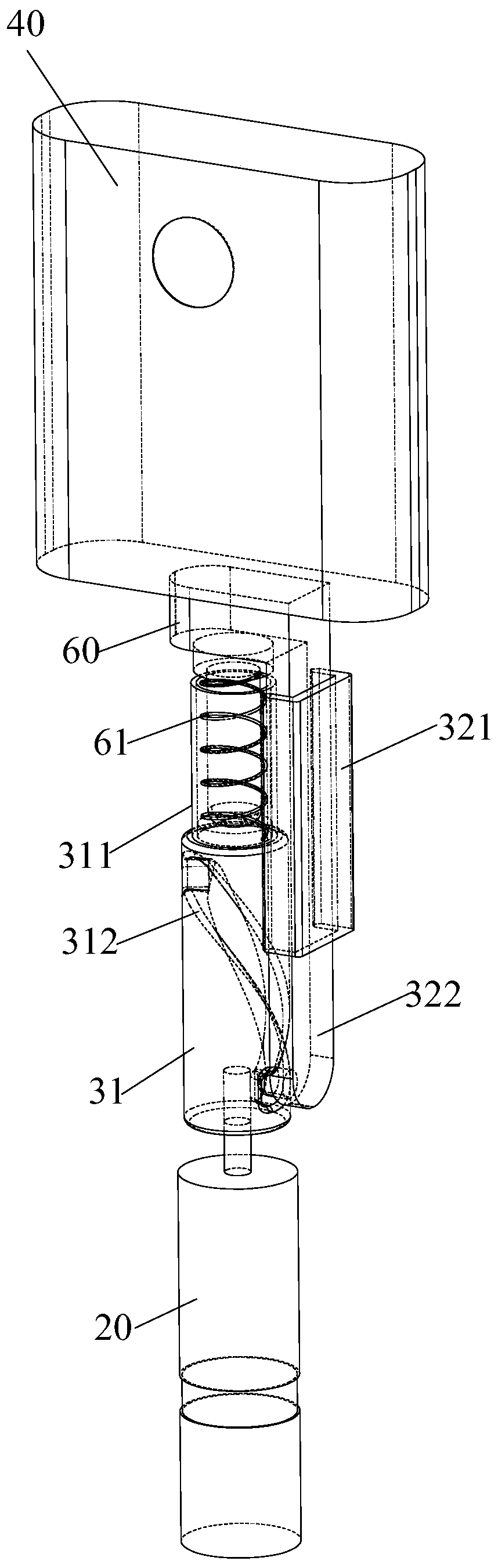

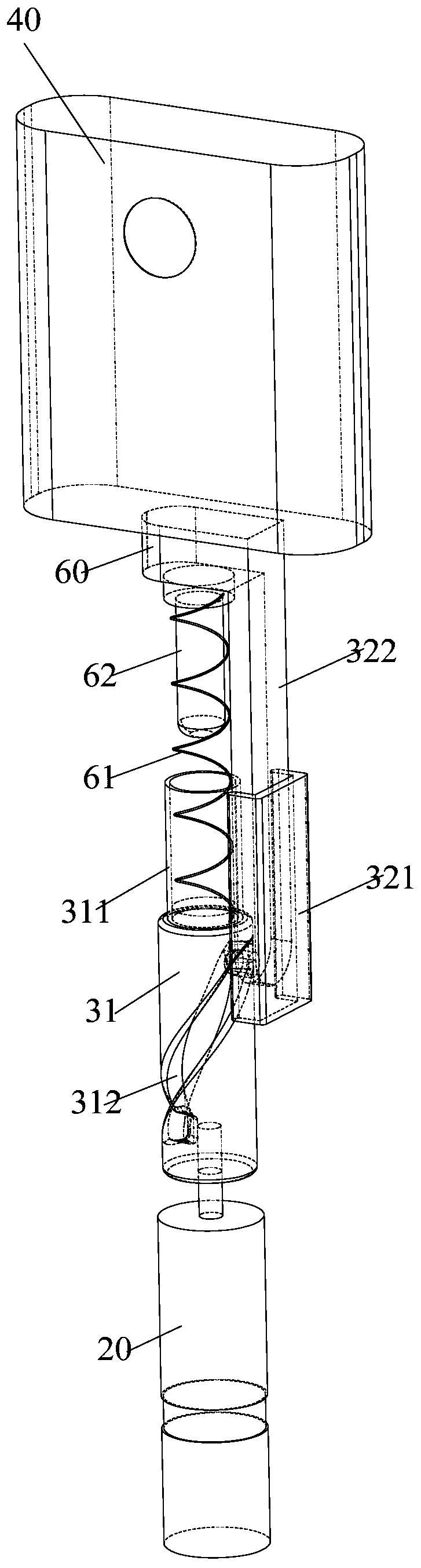

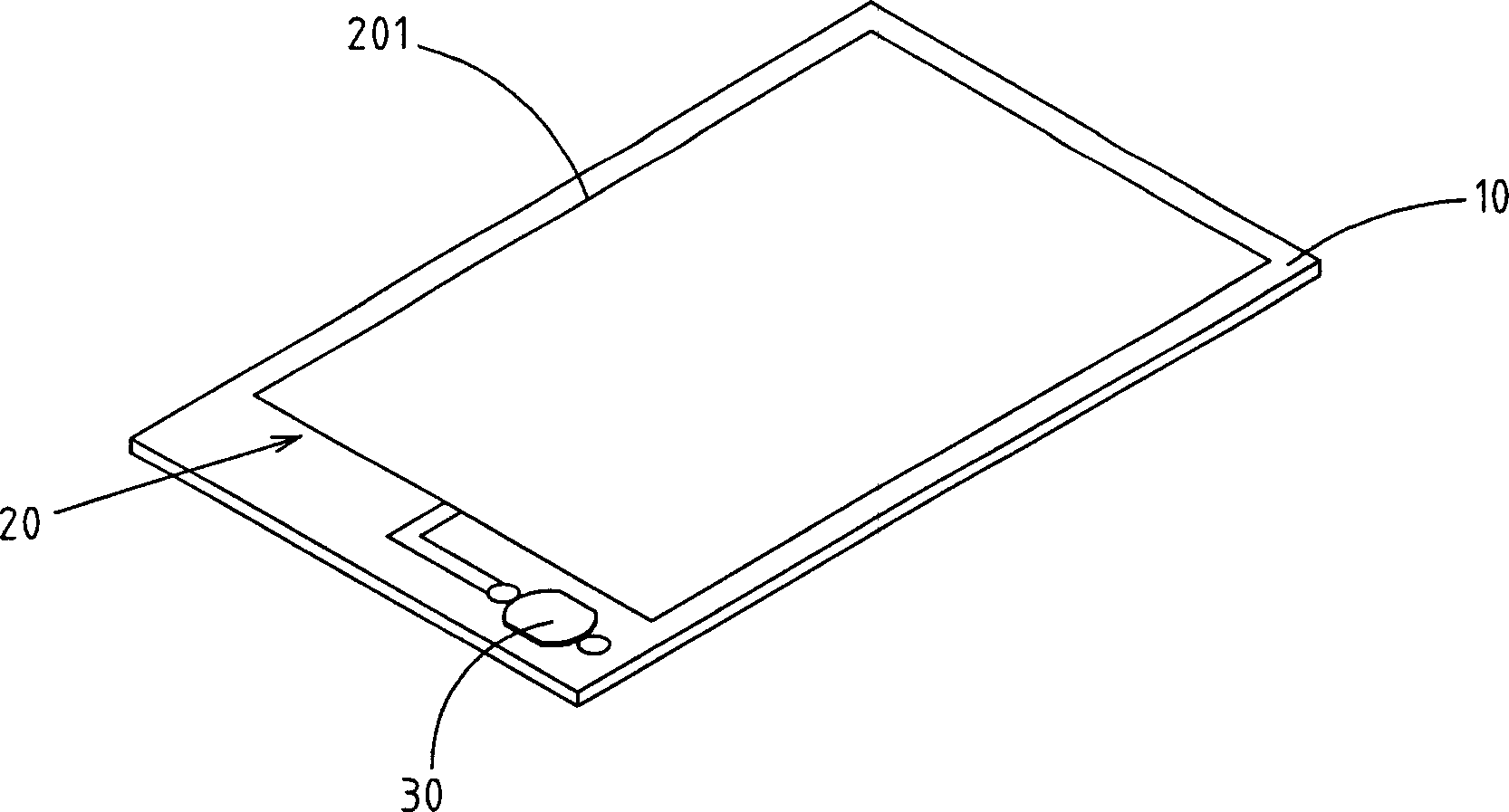

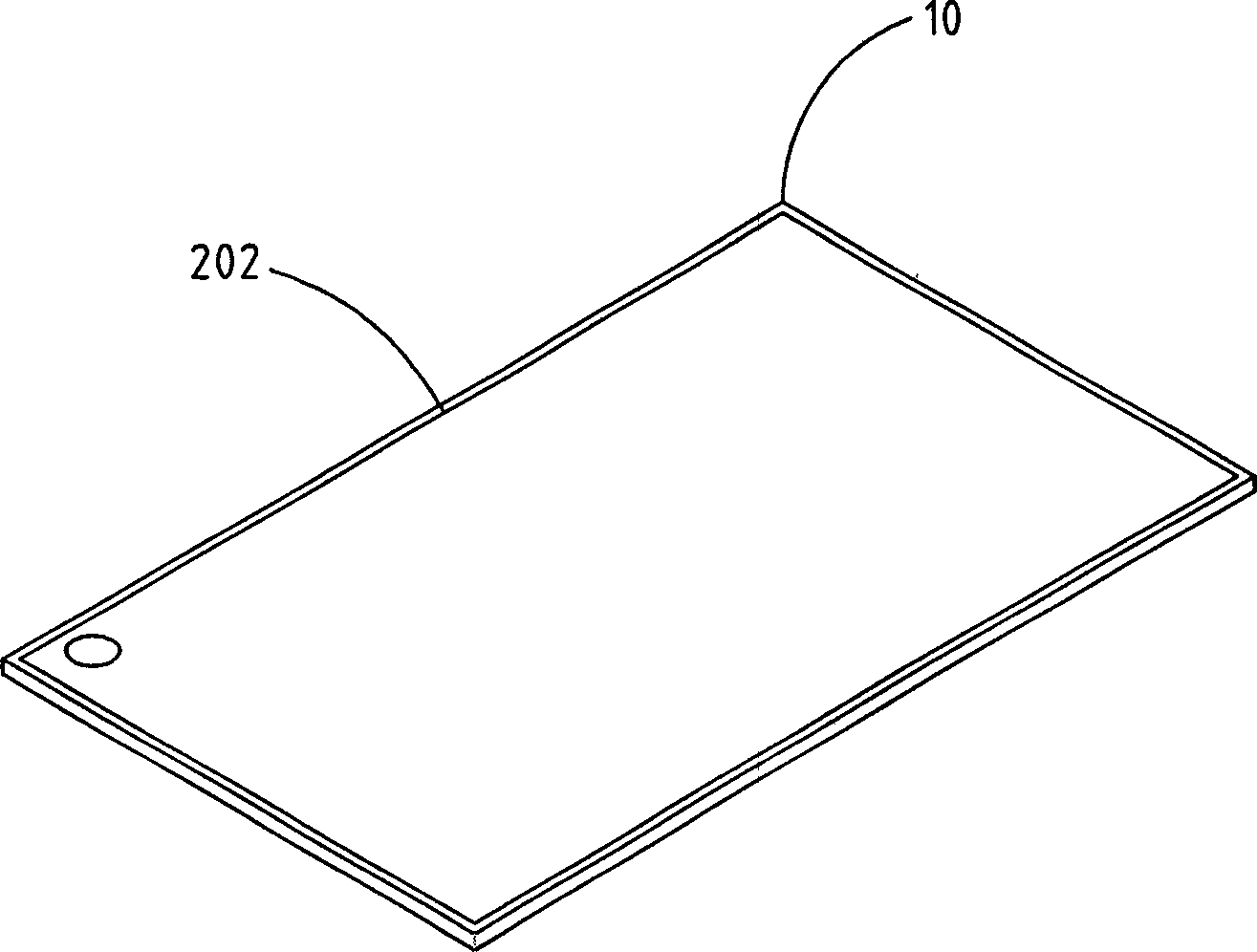

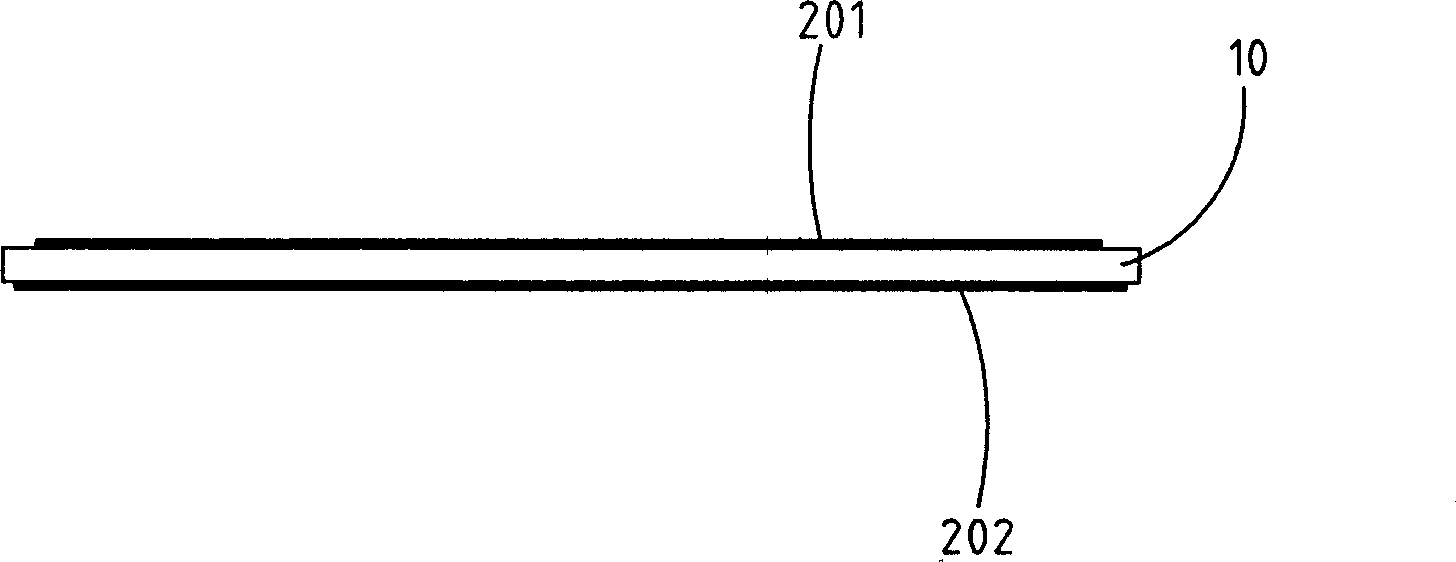

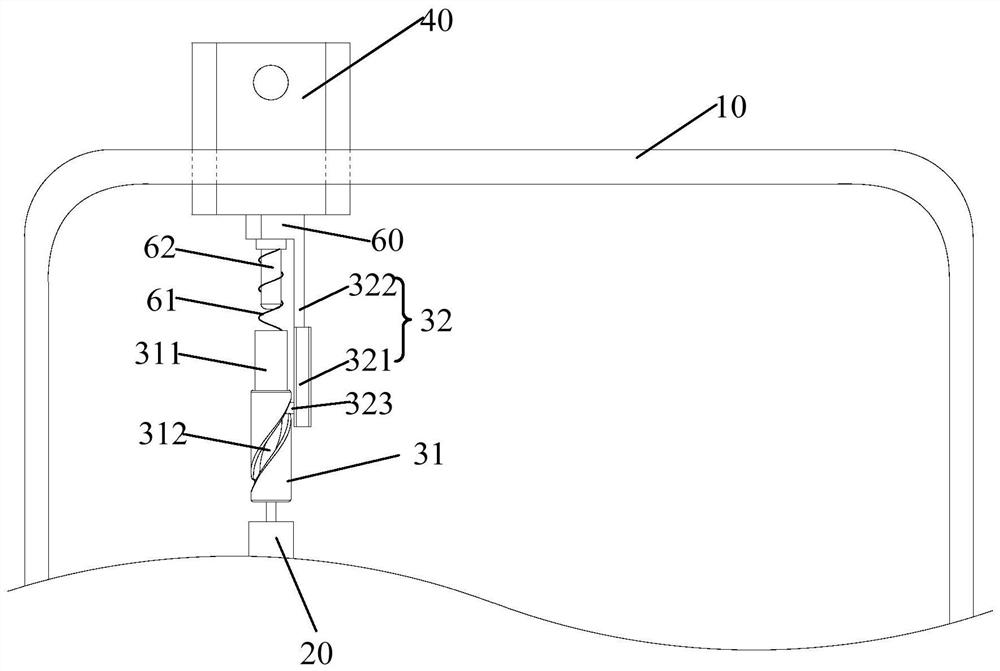

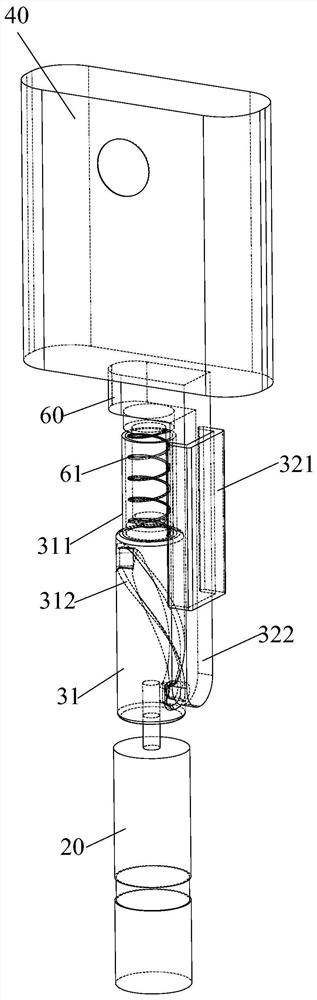

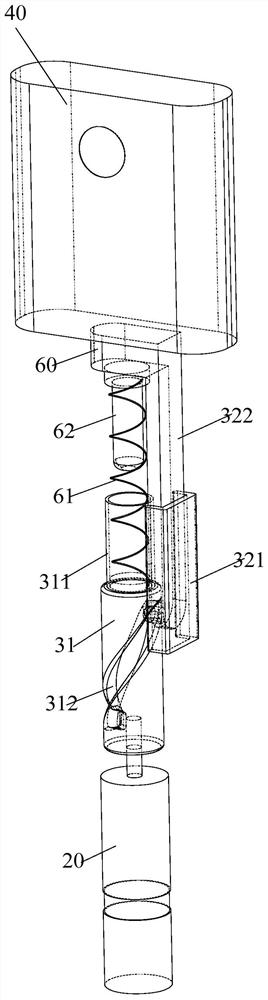

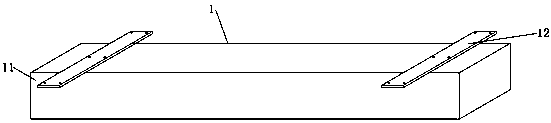

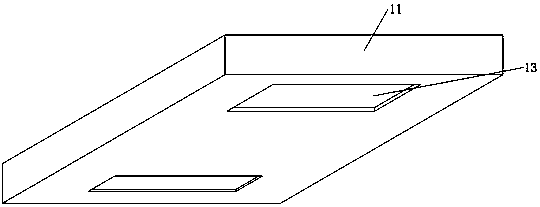

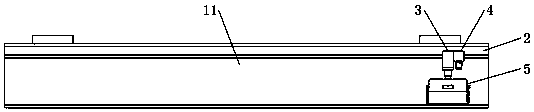

Electronic equipment

ActiveCN111315175AImprove reliabilityAchieve the purpose of transmissionClamping/extracting meansEngineeringControl theory

The invention provides electronic equipment which comprises a shell, a power mechanism, a rotating part, a sliding part and a driven part. The power mechanism, the rotating part and the sliding part are all arranged in the shell; a first end of the rotating part is connected with the power mechanism, and a spiral sliding groove is formed in a surface of the rotating part; a first end of the sliding part is connected with the driven part, and a first sliding block matched with the spiral sliding groove is arranged on the sliding part; and the power mechanism drives the rotating part to rotate and drives the first sliding block to slide in the spiral sliding groove such that the driven part has a first state of extending out of the shell and a second state of being accommodated in the shell.According to the embodiment of the invention, the purpose of transmission is achieved through the cooperative work of the rotating part and the sliding part, and the effect of resisting external force impact force of the rotating part and the sliding part is better such that the reliability of driving the driven part is enhanced.

Owner:VIVO MOBILE COMM HANGZHOU CO LTD

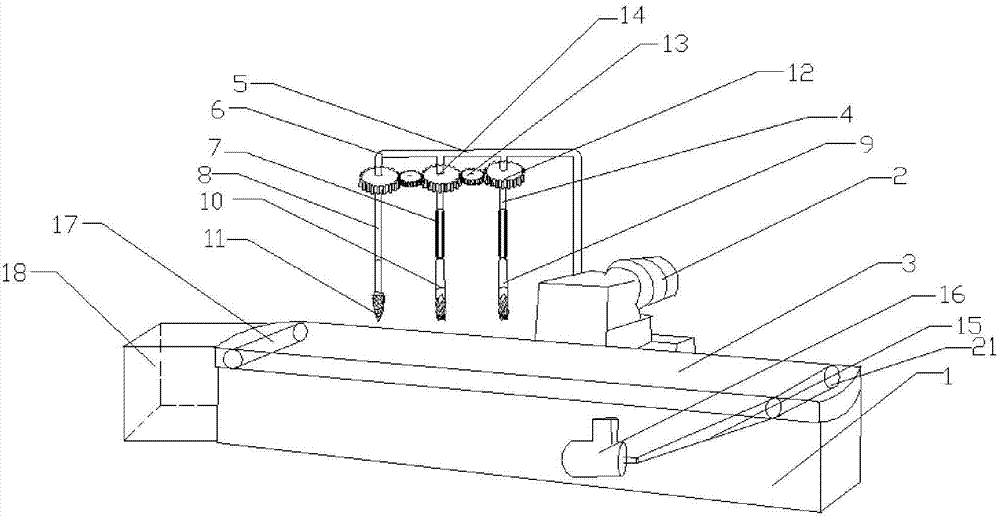

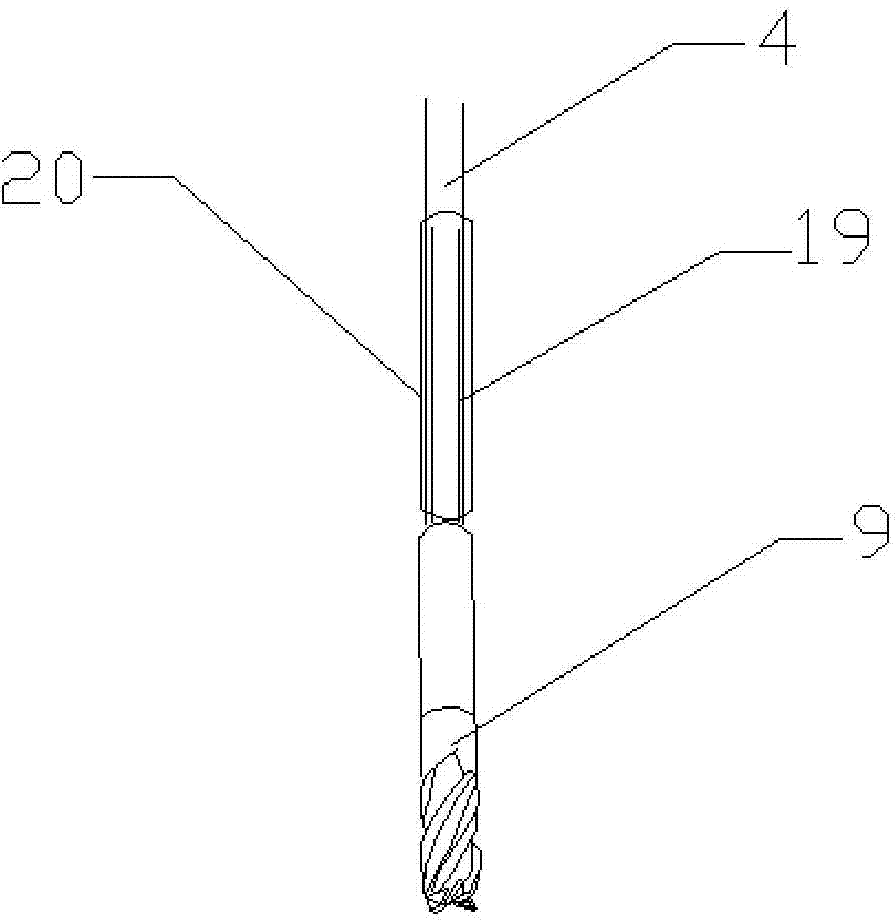

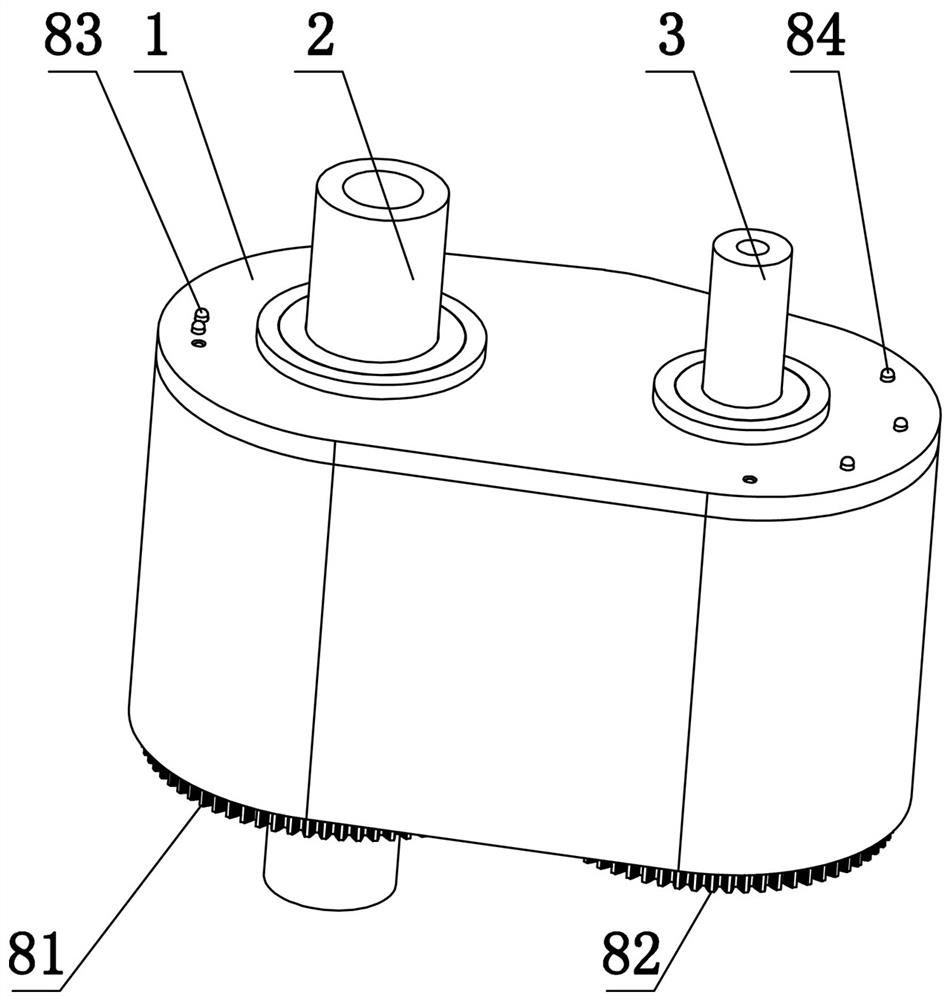

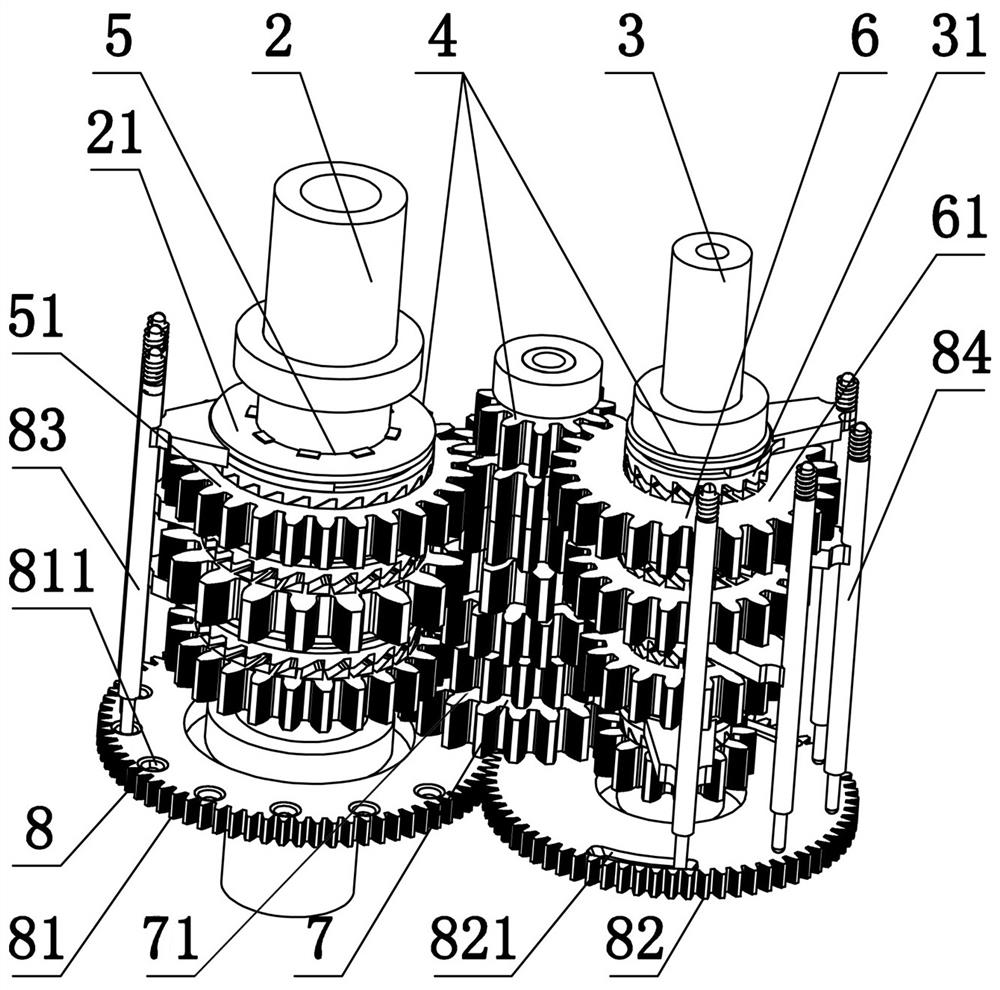

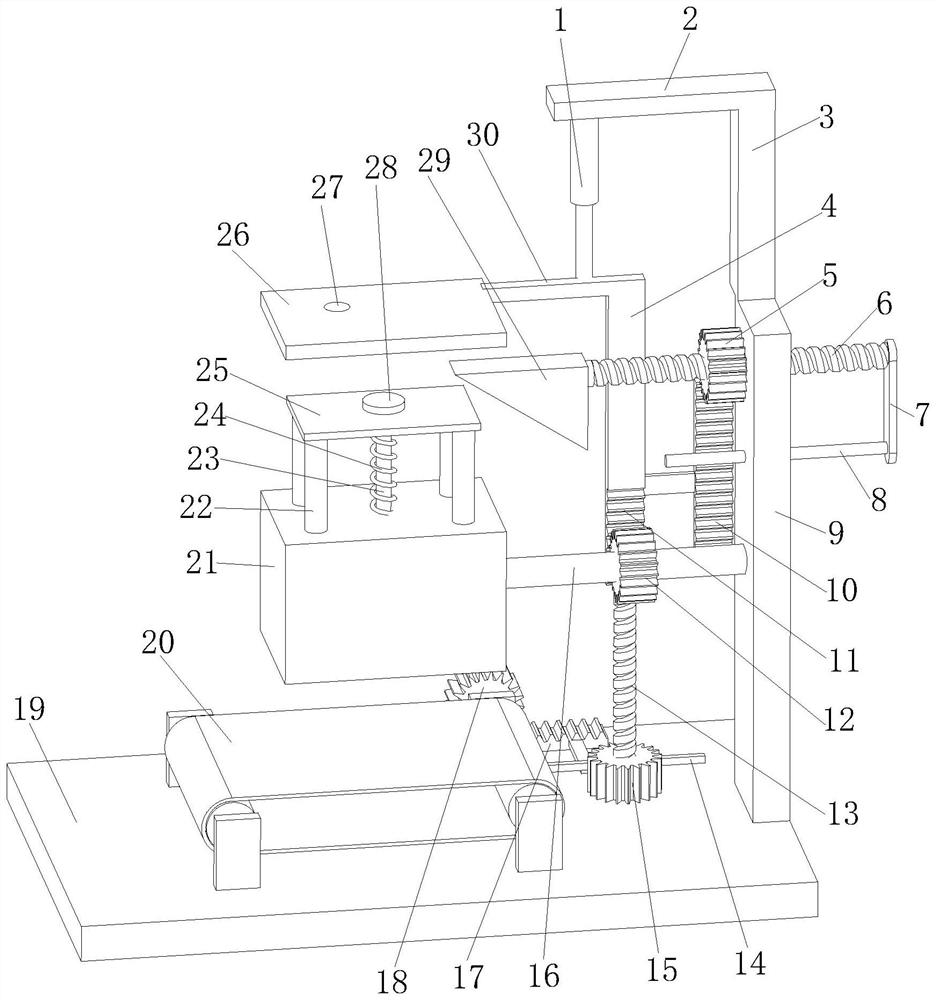

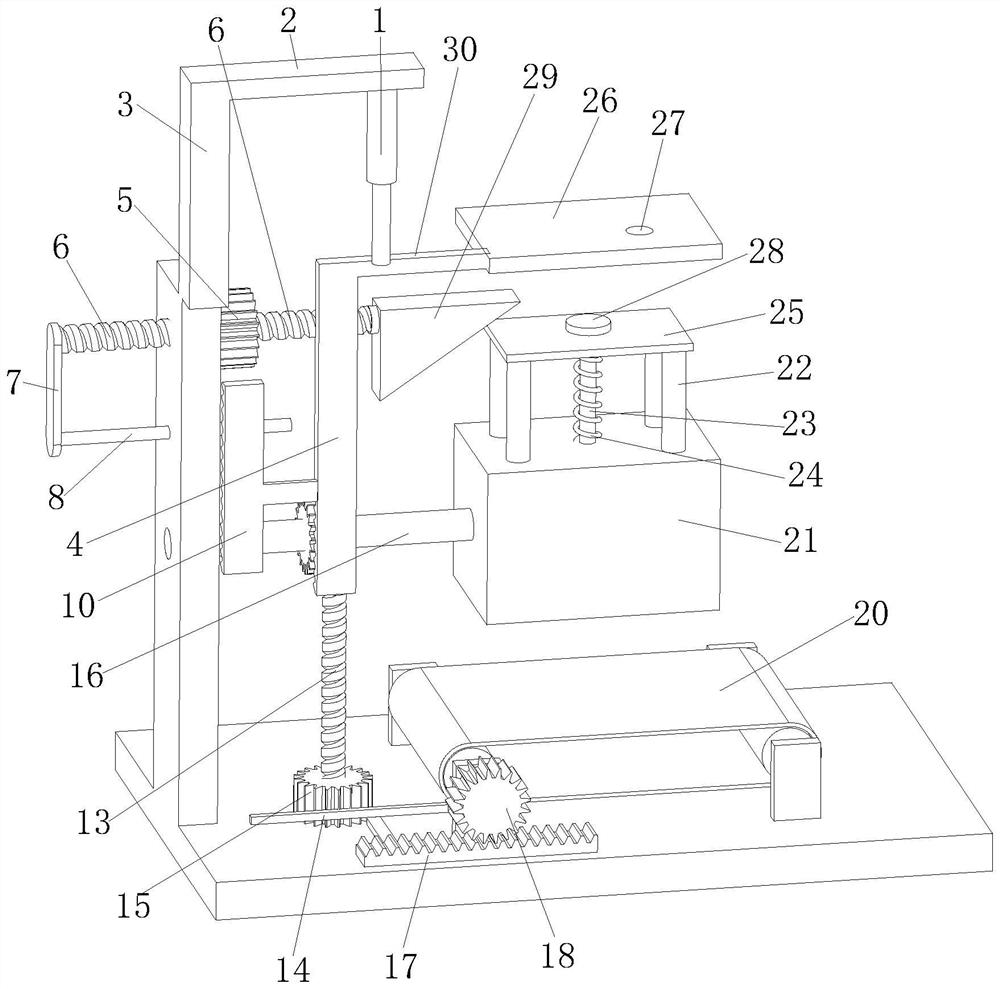

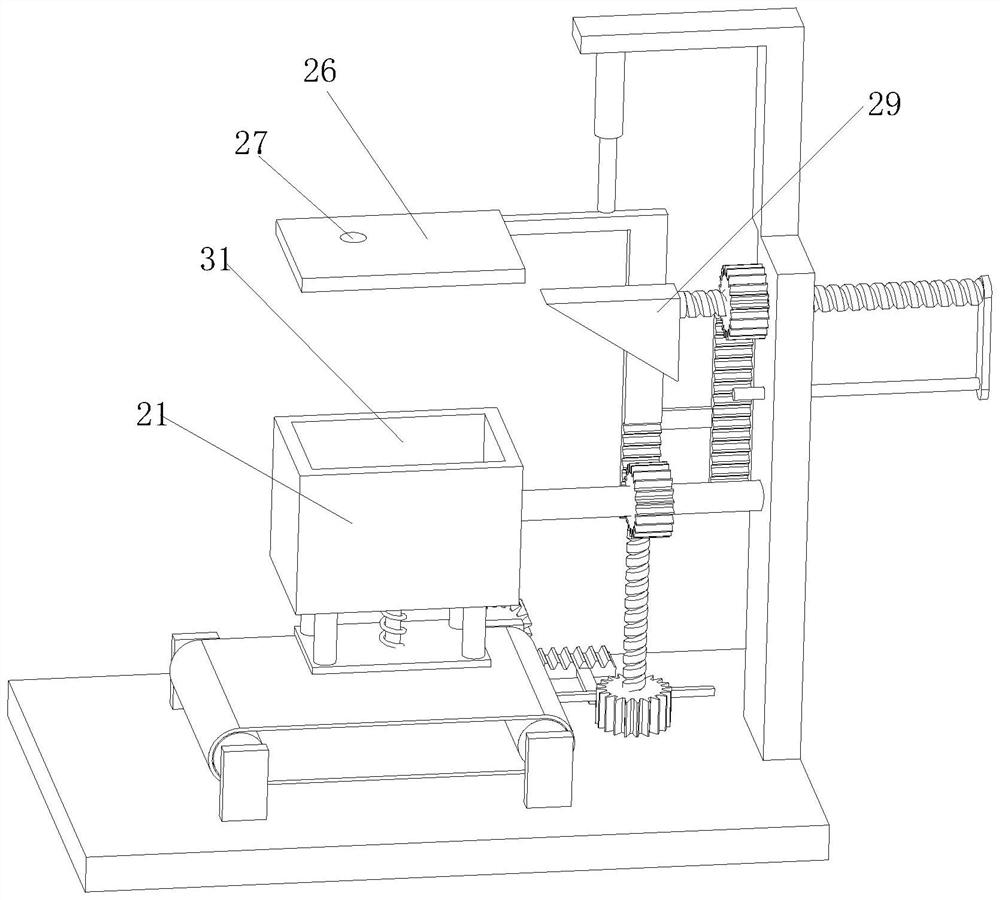

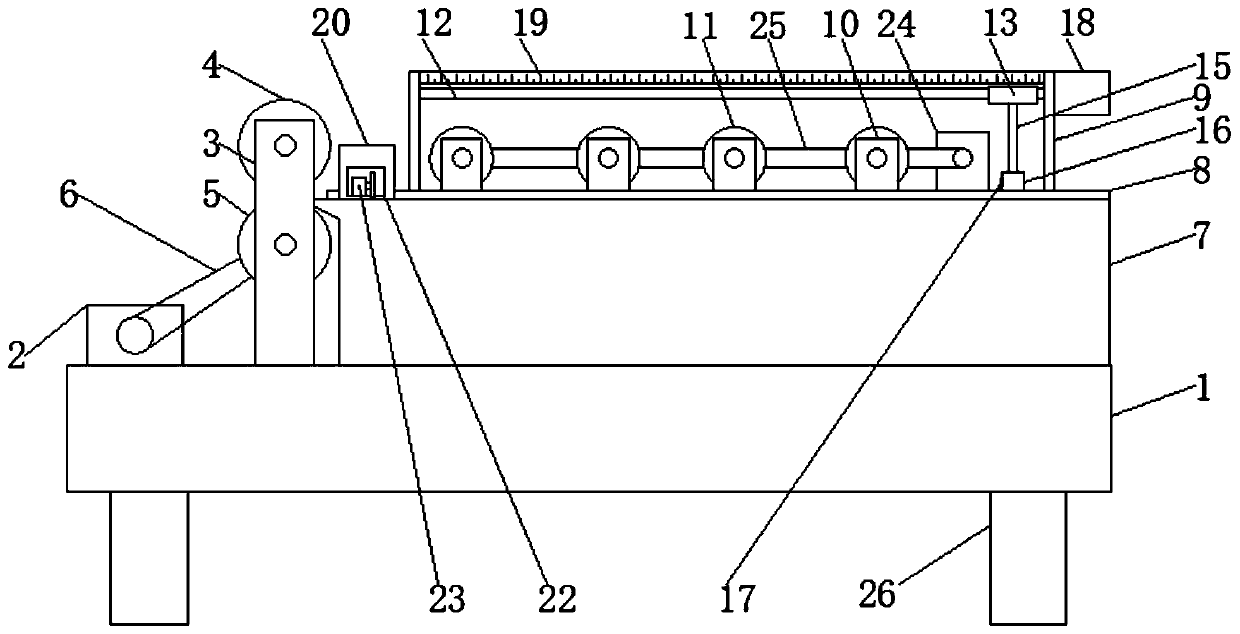

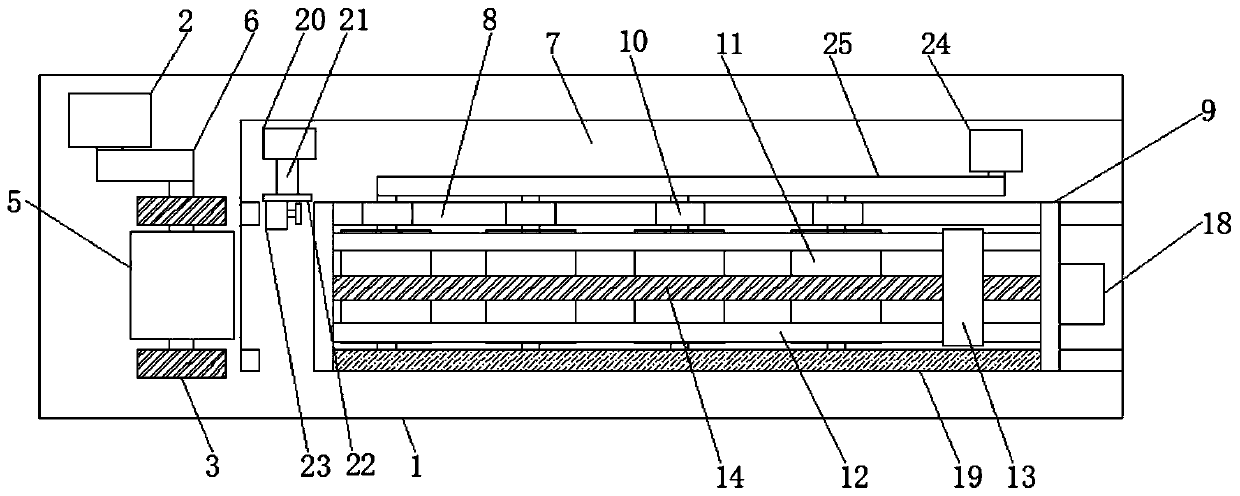

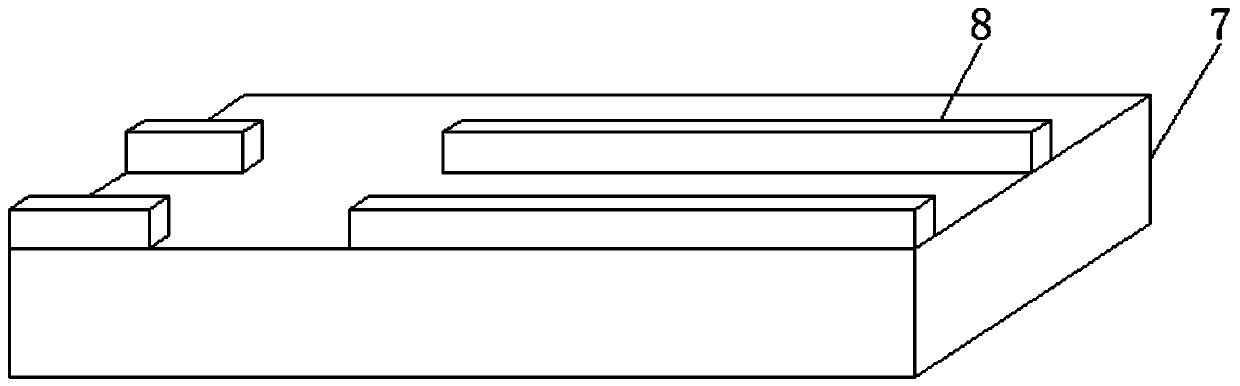

Device for finish milling of mold bases

InactiveCN104289912ARealize streamlined operationImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersMilling cutterAgricultural engineering

The invention relates to the field of steel mold base processing machines, in particular to a device for finish milling of mold bases. The device comprises a rack, a motor and a conveying belt are arranged on the rack, the motor is connected with a main milling shaft, the main milling shaft is connected with an auxiliary milling shaft through a milling shaft transmission mechanism, the auxiliary milling shaft is connected with a filing shaft through a filing shaft transmission mechanism, the bottom end of the main milling shaft is connected with a main milling cutter, the bottom end of the auxiliary milling shaft is connected with an auxiliary milling cutter, the bottom end of the filing shaft is connected with a file, the conveying belt is connected with a conveying belt motor through a roller transmission mechanism, the conveying belt motor is located in the rack, and the height of the main milling shaft ranges from 30 cm to 50 cm. The device is used for achieving streamlined operation of finish milling of the mold bases, machining efficiency is greatly improved, and all the mold bases are machined through the same device in the same process so that machining precision can be guaranteed effectively; besides, the structure of the file is added, so workmanship of the mold bases obtained after finish milling is neater and more orderly, and product quality is guaranteed.

Owner:中山市鸿程科研技术服务有限公司

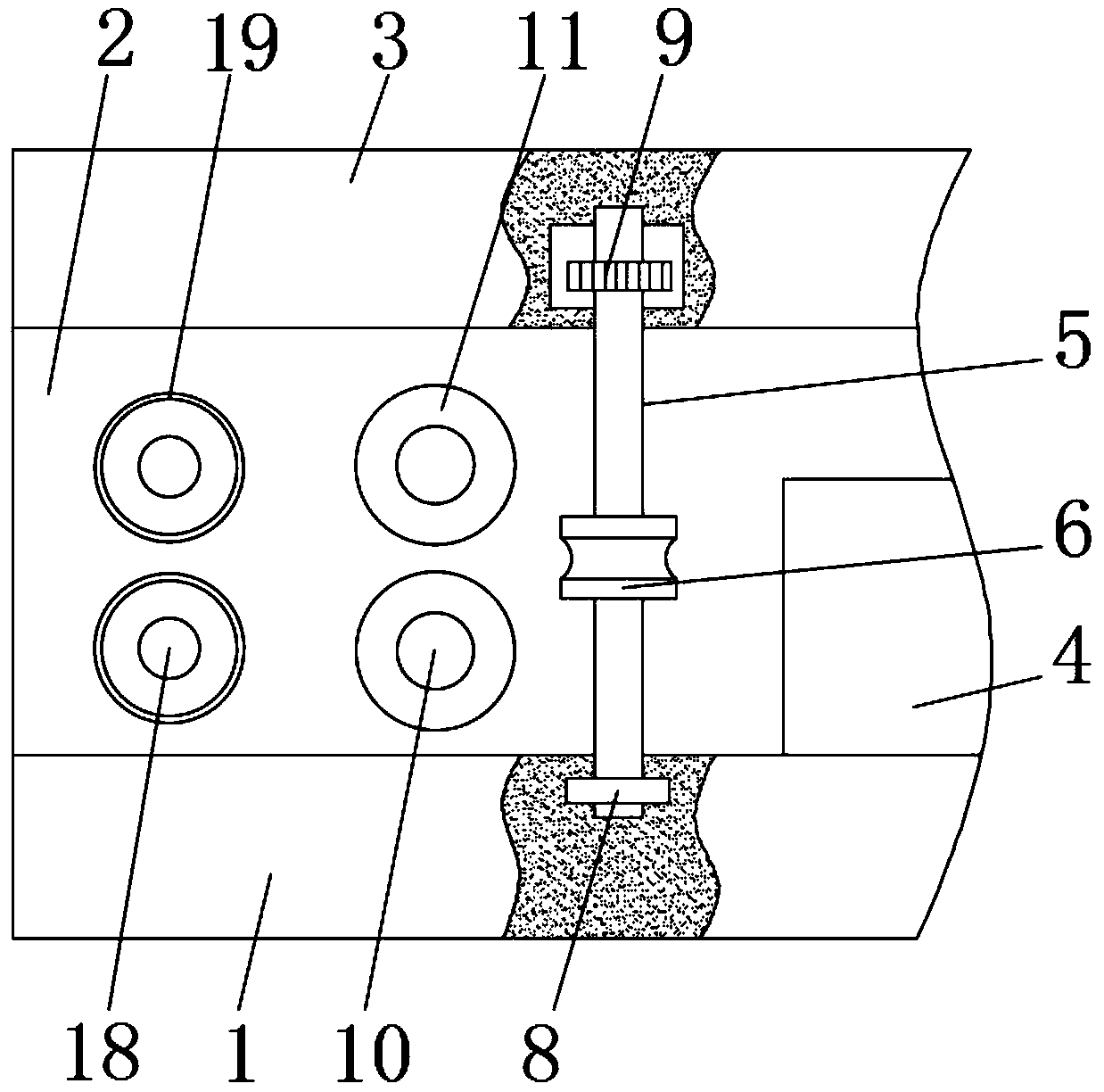

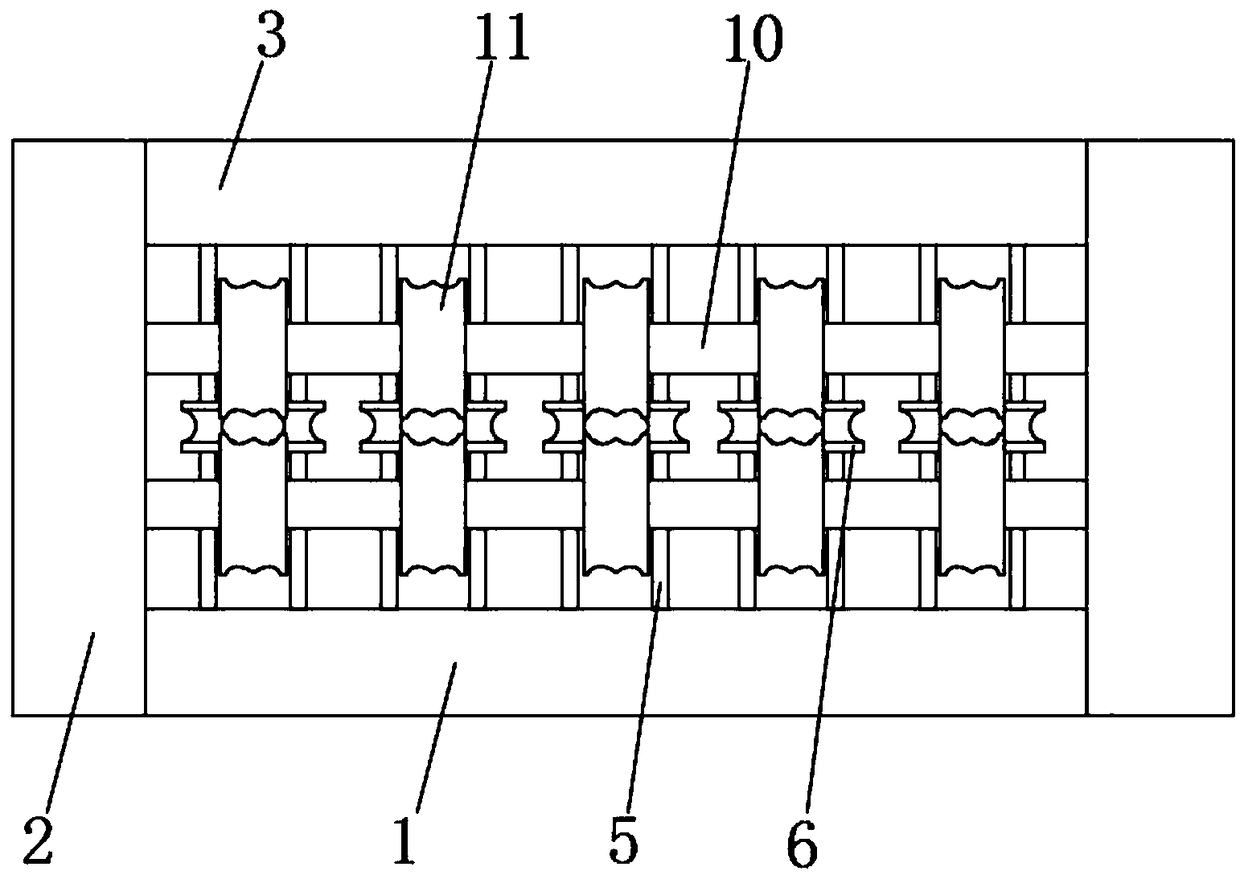

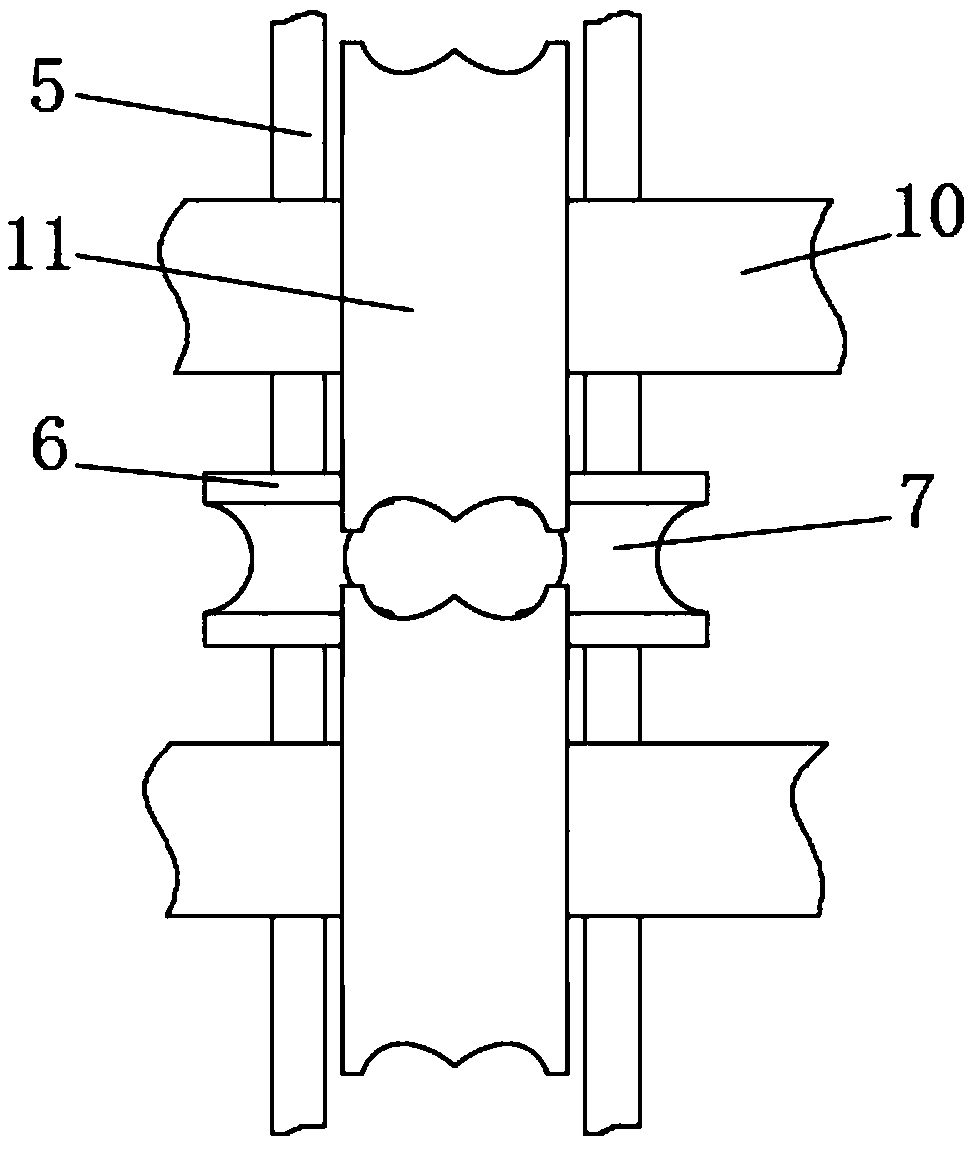

Gearbox in center shaft of bicycle

ActiveCN113401274AAchieve the purpose of transmissionReduced strength requirementsWheel based transmissionGear wheelControl theory

Owner:佛山市顺德区智趣动电子商务有限公司

Grinding device for disposable chopstick roll-groove type forming machine

PendingCN108789739AEfficient processingIncrease productivityWooden sticks manufactureGrinding carriagesArchitectural engineeringGrinding wheel

The invention discloses a grinding device for a disposable chopstick roll-groove type forming machine. The grinding device comprises a base, a mounting rack and a support frame; one end of the top ofthe base is provided with a feeding device, and the middle part of the base is movably connected to one end of a first rotating shaft through a bearing; the other end of the first rotating shaft is located in the mounting rack and is fixedly connected to a speed changing gear, and the support frame is internally provided with a fixed box which is internally provided with a motor; the two ends of the fixed box are both connected to one end of a telescopic rod fixedly, and the other end of the telescopic rod is movably connected to a stop plate of which the two ends are both fixedly connected tothe support frame; and the middle part of the telescopic rod is in dowel joint with a spring of which one end is fixedly connected to the fixed box, and the other end of the spring is fixedly connected to the stop plate. According to the grinding device, through arrangement of two grinding wheels distributed symmetrically, the efficient and fast processing of disposable chopsticks can be achieved; and through arrangement of a plurality of groups of grinding wheels, a plurality of disposable chopsticks can be produced in one time, and the production efficiency is improved.

Owner:衡东县万泉竹业有限公司

Label of wireless radio-frequency identifying system

InactiveCN1893178AAchieve the purpose of transmissionSimple structureAntenna supports/mountingsRadiating elements structural formsElectricityResonance

The tag of radio frequency ID system (RFID TAG) includes dielectric substance base plate attached to antenna body made from electroconductive material, and IC connected to antenna body electrically. The antenna body possesses radiation part and grounded part. The radiation part is formed on one face of dielectric substance base plate, and the grounded part is formed on the other face of dielectric substance base plate. Integral composition of antenna reaches generation of resonance mode or mechanism of radiation, as well as makes both of radiation part and grounded part connect to IC electrically. Integral structure promotes reads data from or writes data to corresponding reader-writer by using RFID TAG.

Owner:WHA YU IND CO LTD

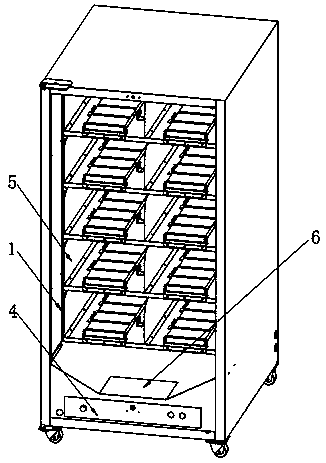

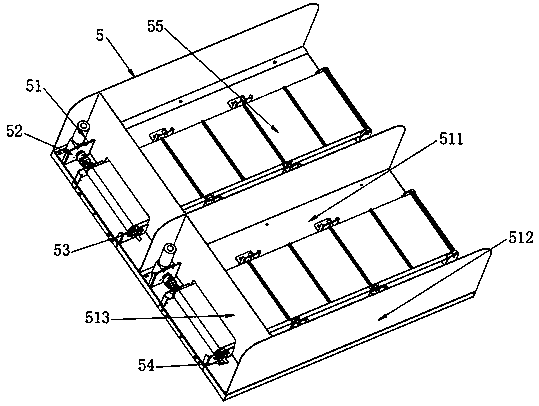

Smart operating room shoe sending machine

PendingCN111091661AReach deliveryAchieve the purpose of transmissionApparatus for meter-controlled dispensingElectric machineryEngineering

The invention discloses an intelligent operating room shoe sending machine, comprising a box body, a cabinet door, a shoe-taking opening, a drawer, shoe-taking components and a shoe cavity, wherein the cabinet door is mounted on the front surface of the box body by a hinge, the plurality of groups of shoe-taking components are mounted equidistantly inside the box body from top to bottom, each shoe-taking component comprises a shoe-carrying component, a base, side plates and a baffle with a through hole in the middle of the bottom, the side plates are fixedly mounted on two sides and in the middles of the tops of the bases, each side plate in the middle position is symmetrically connected with the corresponding side plates on two sides through the corresponding baffle plate with the throughhole in the middle of the bottom to form two shoe carrying cavities, the shoe-carrying components are mounted in the shoe carrying cavities, each shoe-carrying component comprises a turbo-worm motor,a motor base, a bearing base, a driving roller, a conveyor belt, a support a, a support b, a bracket, a passive roller and a guide roller, and the motor bases are mounted at certain ends of the topsof the bases. The intelligent operating room shoe sending machine replaces manpower to send shoes, improves the work efficiency, meanwhile reduces labor intensity, and saves labor costs.

Owner:苏州艾普乐医疗科技有限公司

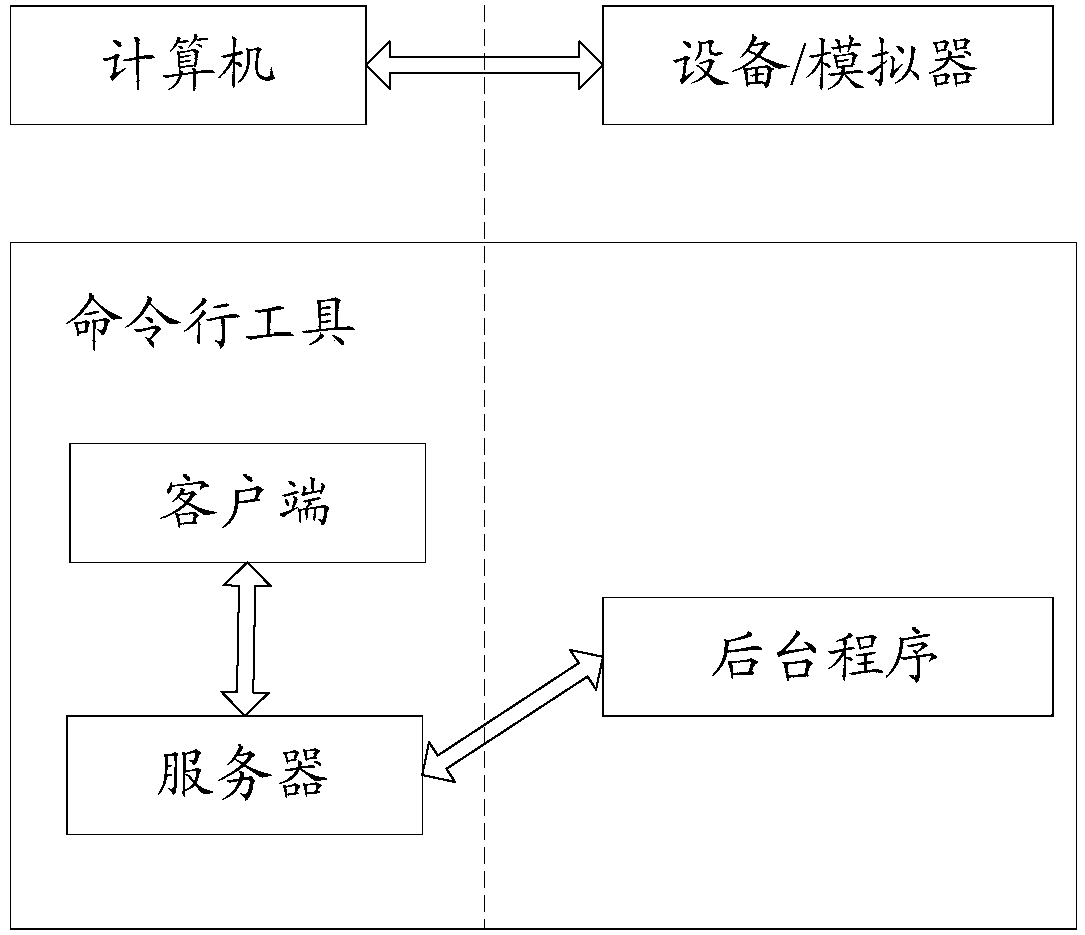

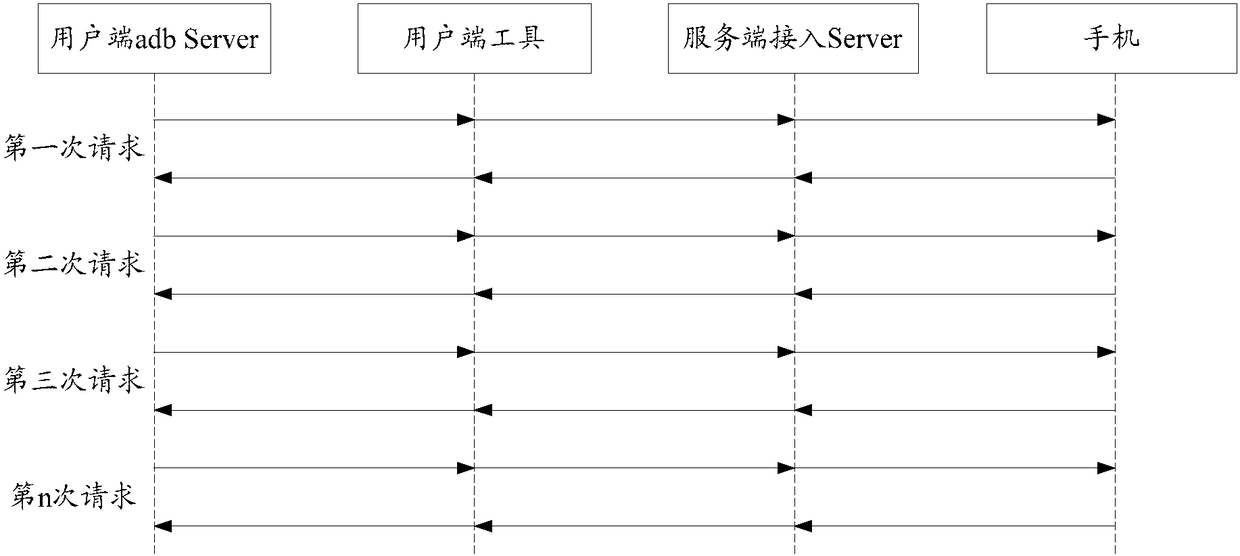

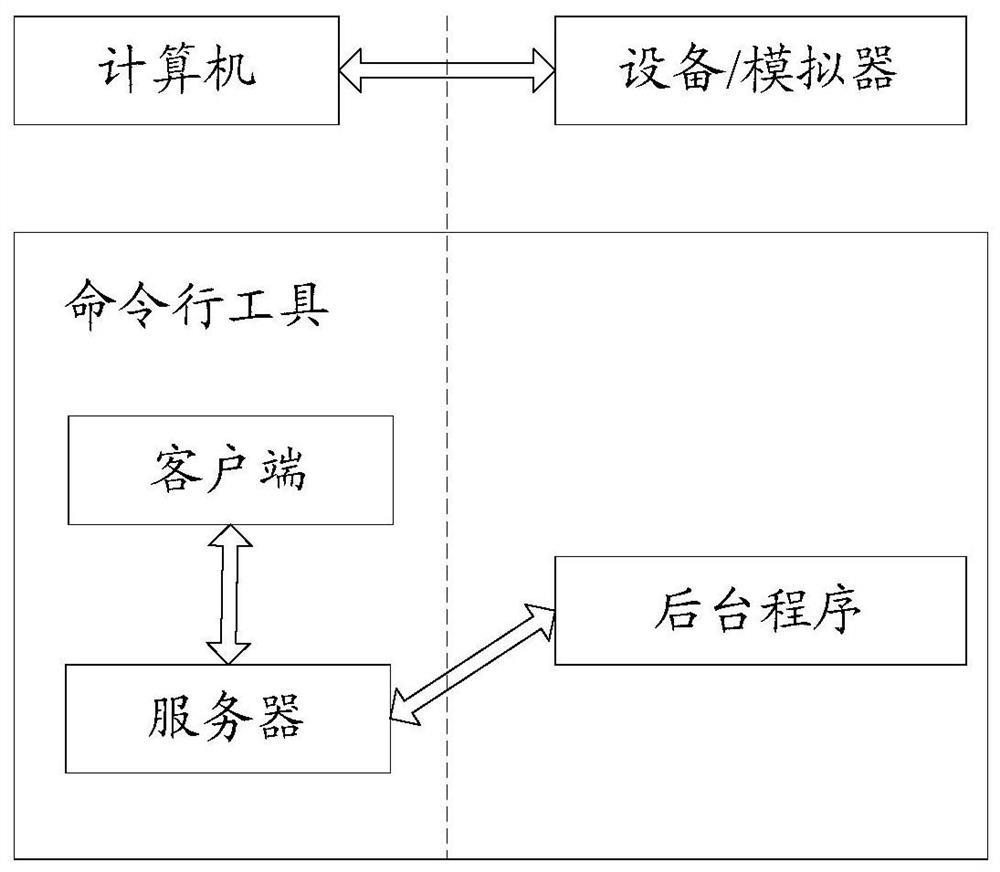

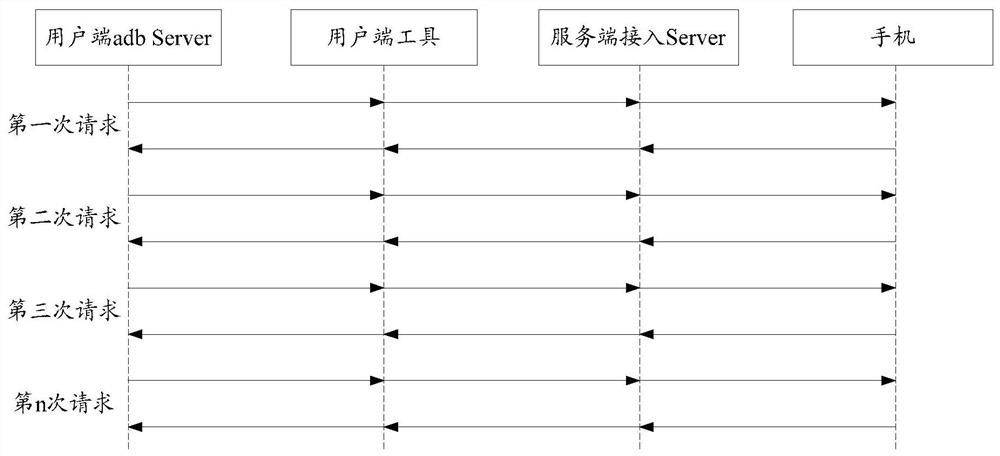

Data transmission method and device

ActiveCN108628683AAchieve the purpose of transmissionImprove transmission efficiencyInterprogram communicationTransmissionData transmissionComputer science

The invention discloses a data transmission method and device. The method comprises the following steps of: receiving a first request sent by a first target object; in response to the first request, sending a first response message to the first target object and transmitting first target data to a second target object through a network, wherein the first response message is used for simulating a response message sent by the second target object after receiving the first target data; receiving a second request sent by the first target object in response to the first response message, wherein the second request is used for requesting to transmit second target data for remote debugging to the second target object through the network; and in response to the second request, sending a second response message to the first target object and transmitting the second target data to the second target object through the network, wherein the second response message is used for simulating a responsemessage sent by the second target object after receiving the second target data. According to the method and device, the technical problem that the data transmission efficiency is low in correlation technique is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

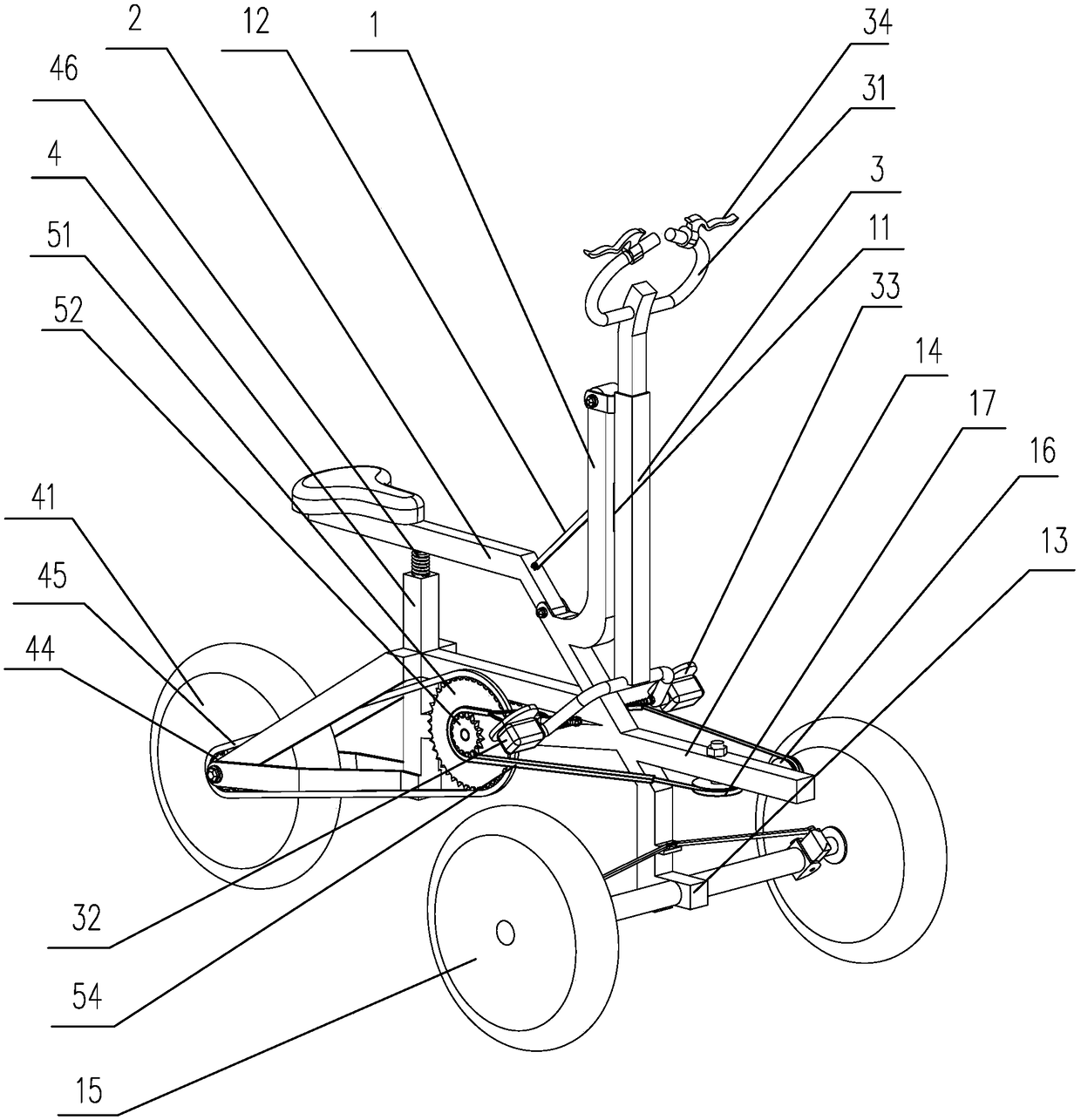

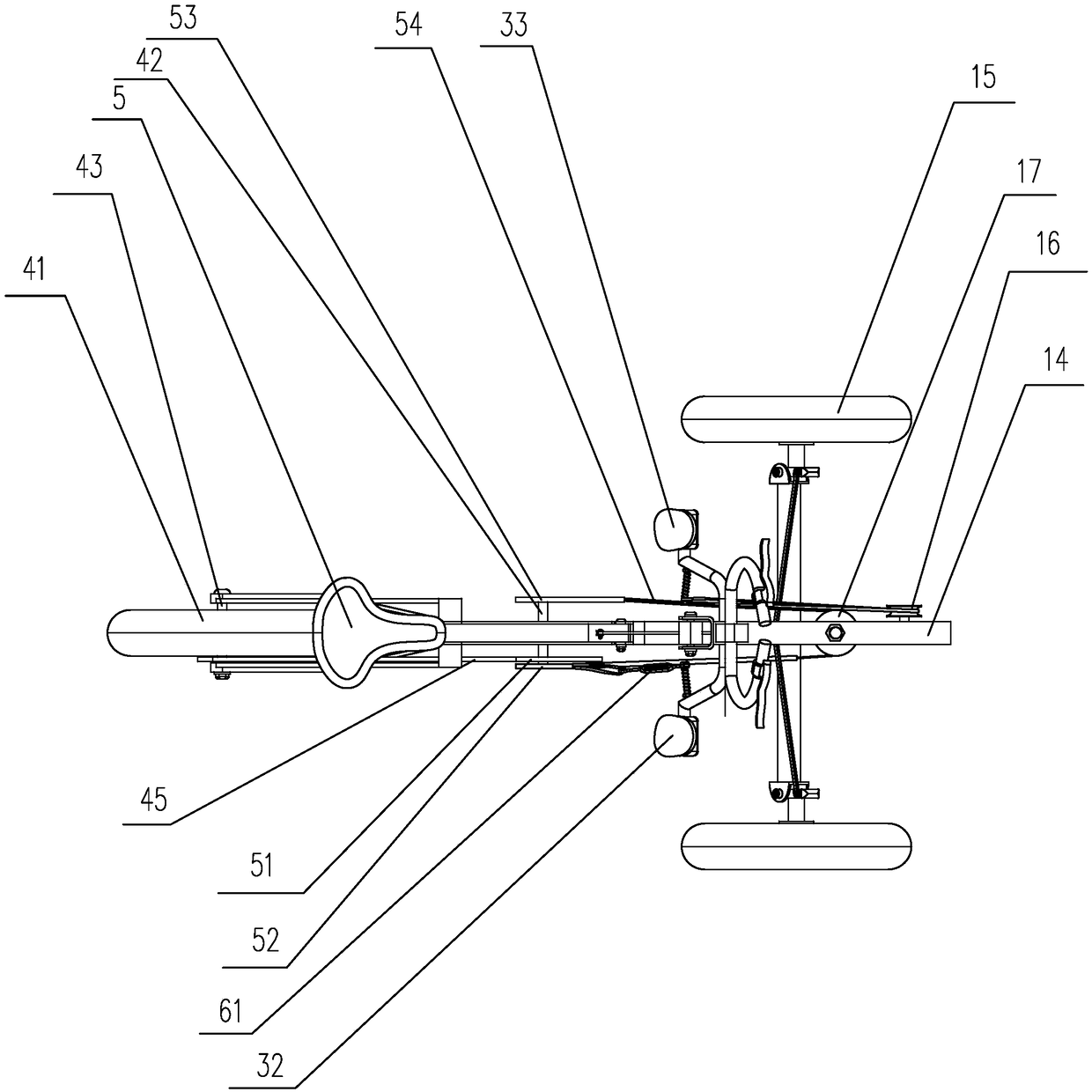

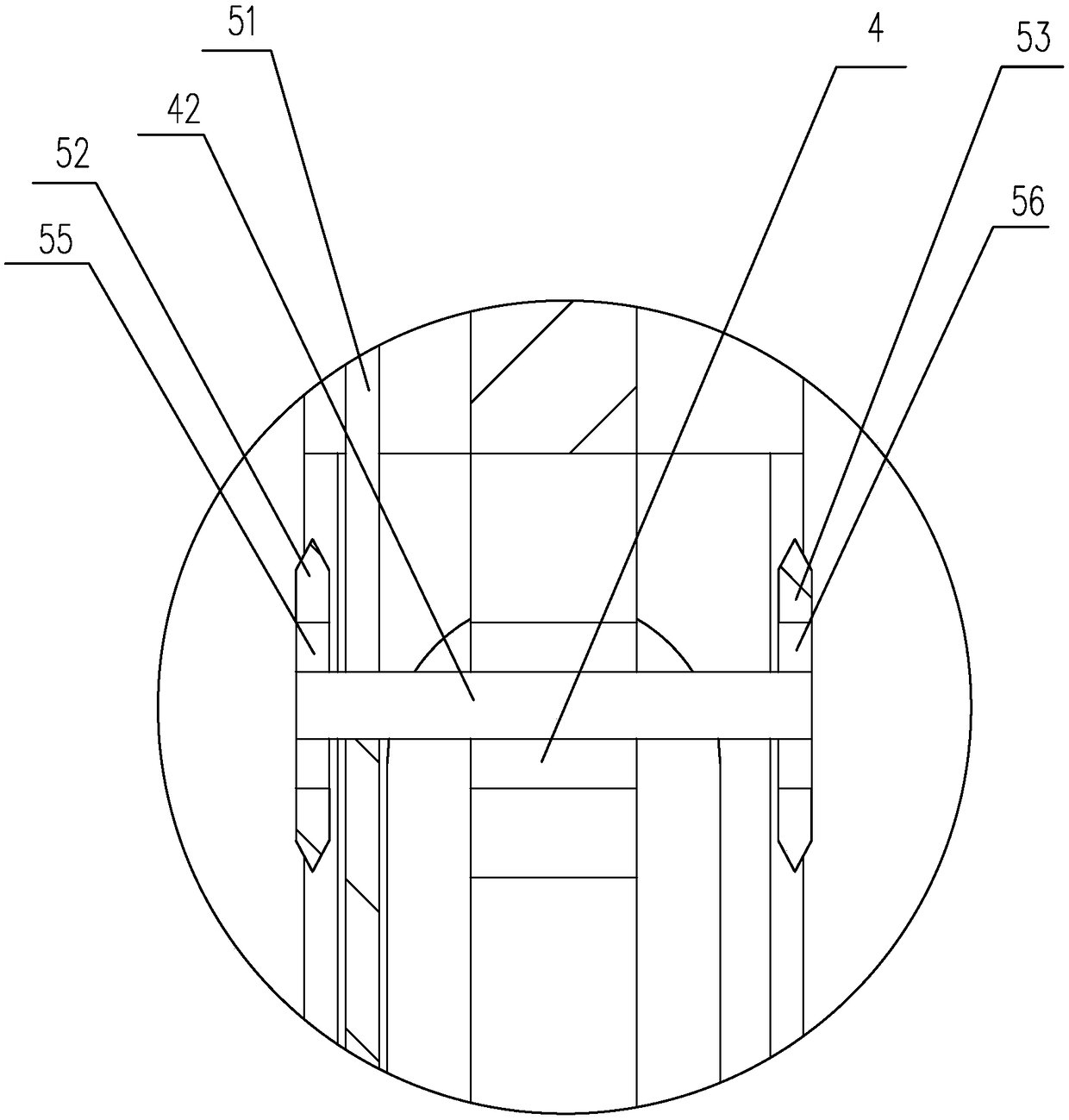

Horse-riding-type bicycle

The invention discloses a horse-riding-type bicycle which comprises a horse-riding frame. The horse-riding frame comprises a seat bracket, a grip handle bracket and a connecting frame. Pedals are arranged at the lower end of the grip handle bracket. The seat bracket is hinged to one end of the connecting frame. The grip handle bracket is hinged to the other end of the connecting frame. A connecting rod is connected between the grip handle bracket and the seat bracket. A front wheel mounting frame and an auxiliary bracket are further arranged on the connecting frame in an extending mode. The front wheel mounting frame is provided with front wheels. The front wheels are provided with steering mechanisms. The horse-riding-type bicycle further comprises a travelling frame and a transmission mechanism. The travelling frame is connected with the connecting frame. The travelling frame is provided with a rotating shaft. The transmission mechanism comprises two sprockets, a transmission belt and a guide wheel set. The guide wheel set comprises a plurality of guide wheels. The two sprockets are arranged at the two ends of the rotating shaft through two unidirectional flywheels correspondingly. The two unidirectional flywheels are arranged oppositely. The two sprockets are in transmission connection through the transmission belt. The two ends of the transmission belt are connected to thetwo pedals correspondingly and sequentially penetrate through all the guide wheels.

Owner:陈裕俊

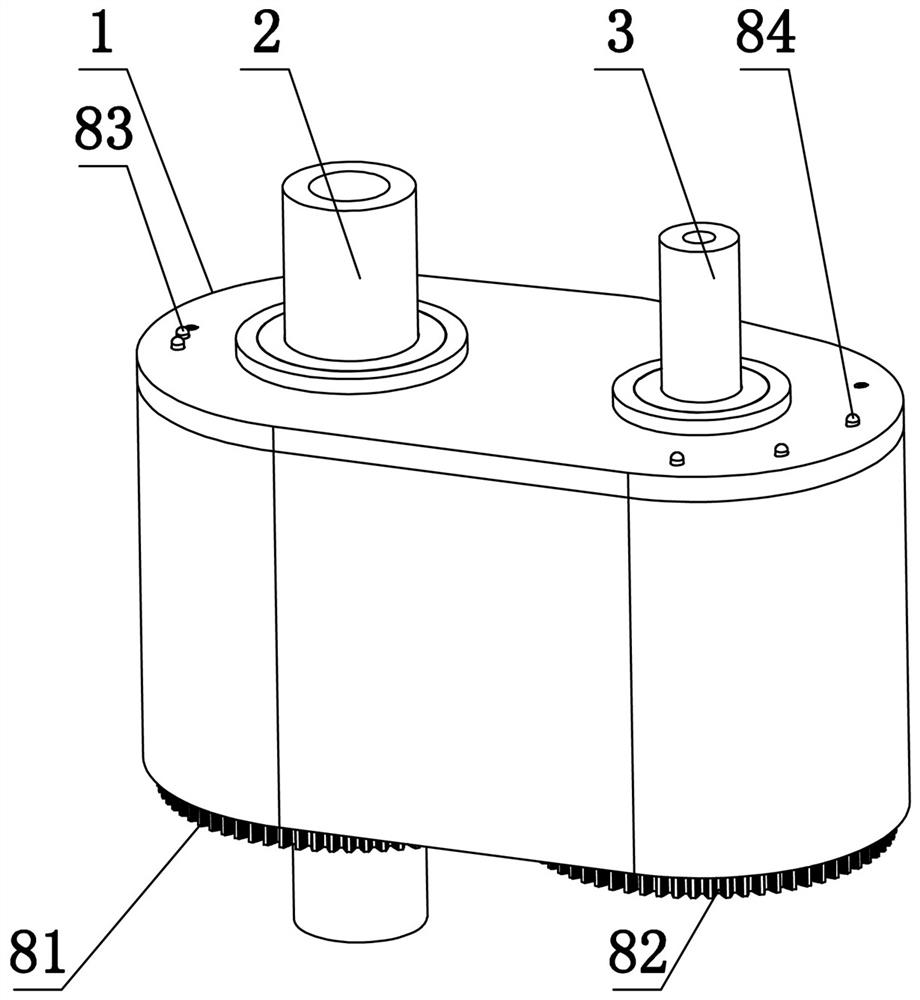

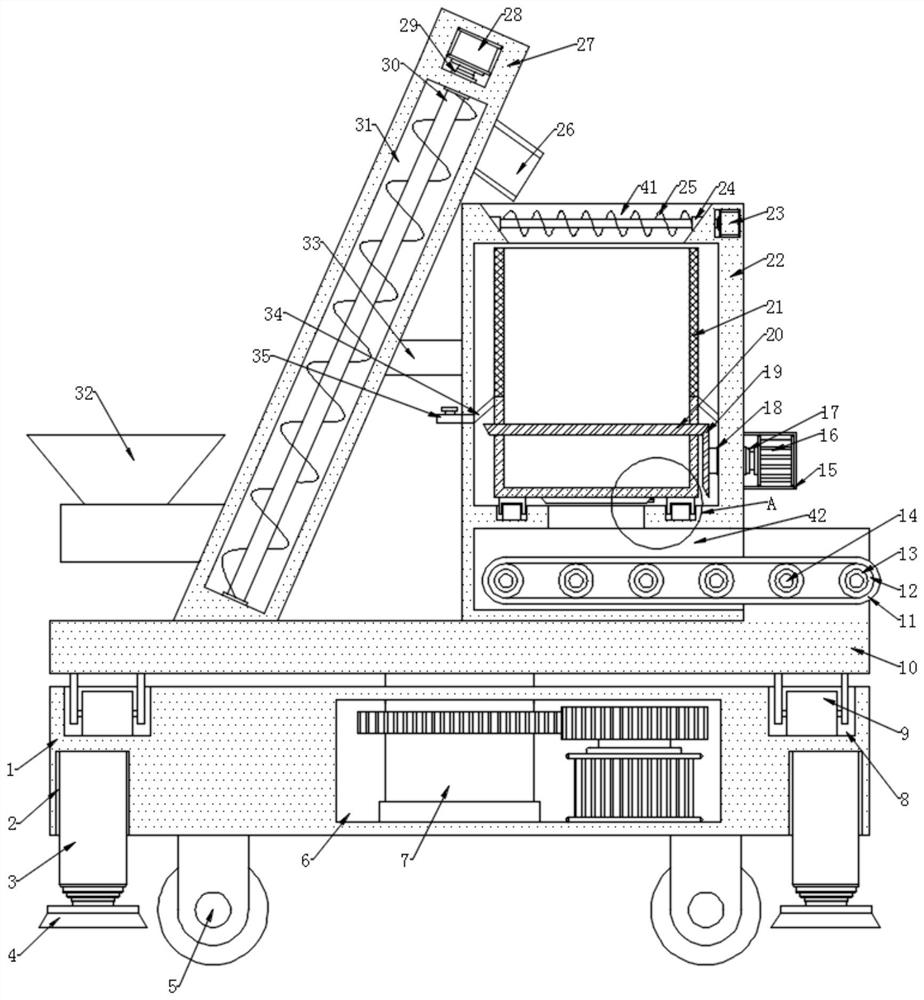

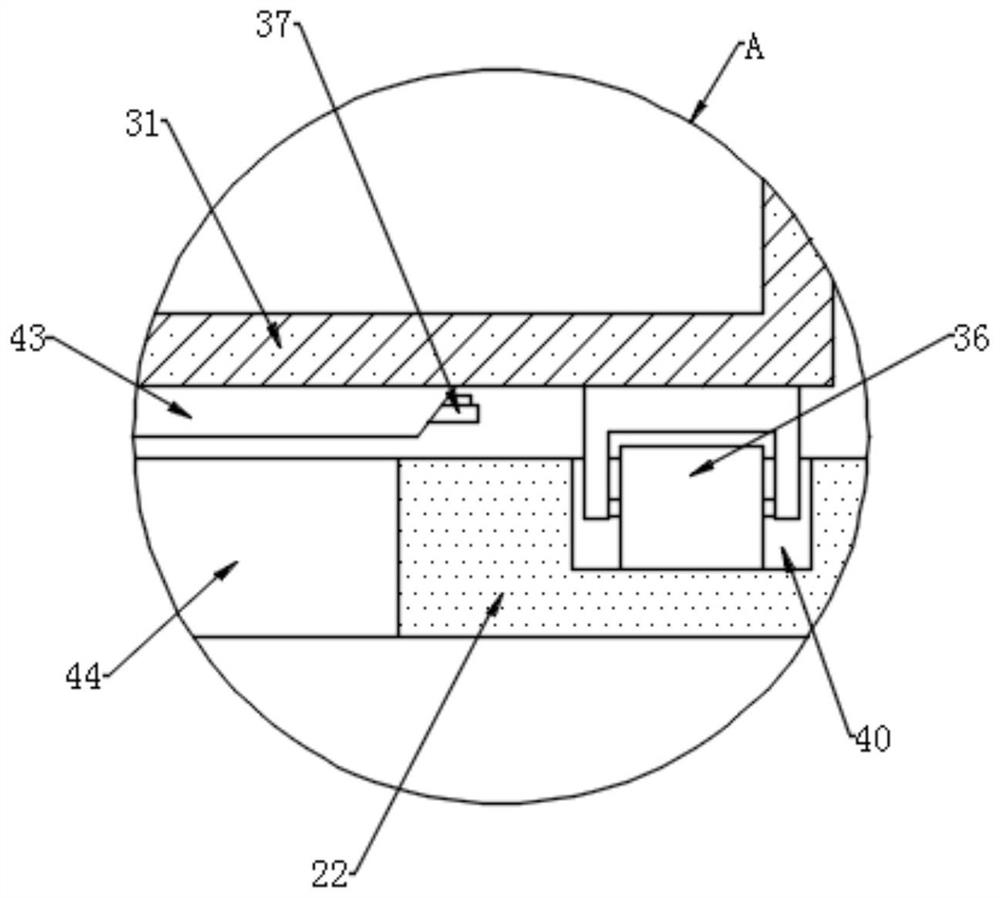

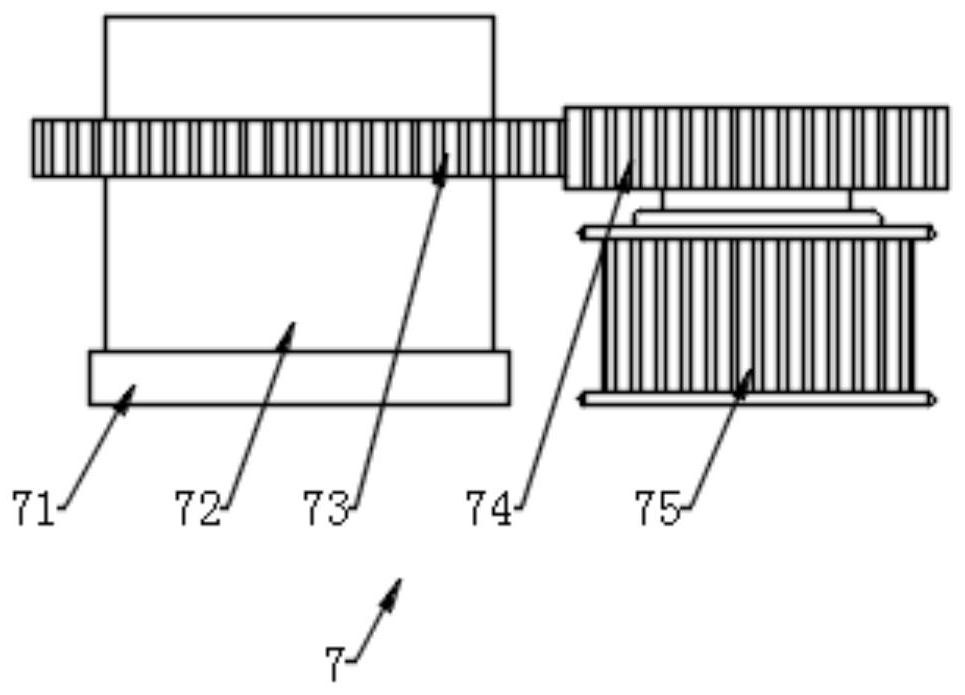

Adjustable centrifugal coal washing mechanism with automatic conveying mechanism

PendingCN112676241AHigh flexibilityRealize the use of altitude and azimuthPortable framesConveyorsPhysicsElectric machinery

The invention belongs to the technical field of centrifugal coal washing, and relates to an adjustable centrifugal coal washing mechanism with an automatic conveying mechanism. The coal washing mechanism comprises a base, a cavity is formed in the base, a driving assembly is fixedly connected to the interior of the cavity, and the top of the driving assembly penetrates through the cavity and is fixedly connected with a rotating plate. The adjustable centrifugal coal washing mechanism with the automatic conveying mechanism has the beneficial effects that a driving motor in the driving assembly works to drive a driving gear and a driven gear to rotate in a meshing mode, then the rotating plate can be driven to rotate through a first rotating shaft, the purpose of adjusting the use directions of a box body and a barrel body can be achieved, and the use flexibility is high; through cooperation of all structures of the mechanism, the purposes of automatic material conveying and material transferring are achieved while the purpose of coal washing is achieved, and the use height and direction of the mechanism can be flexibly adjusted; and the whole mechanism is reasonable in structure, convenient to use and high in practicability.

Owner:杨建南

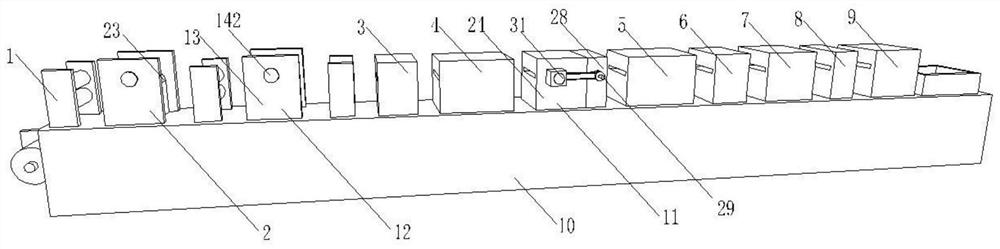

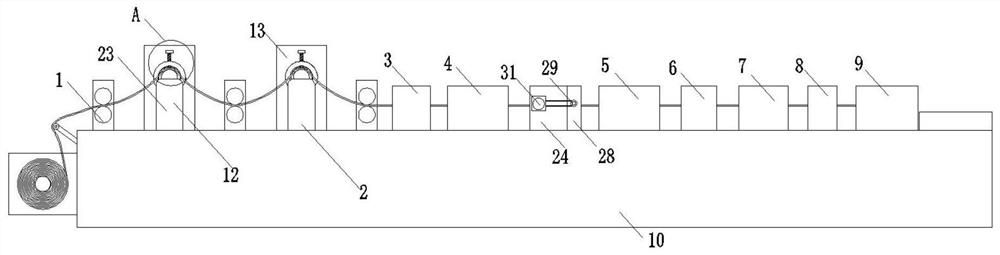

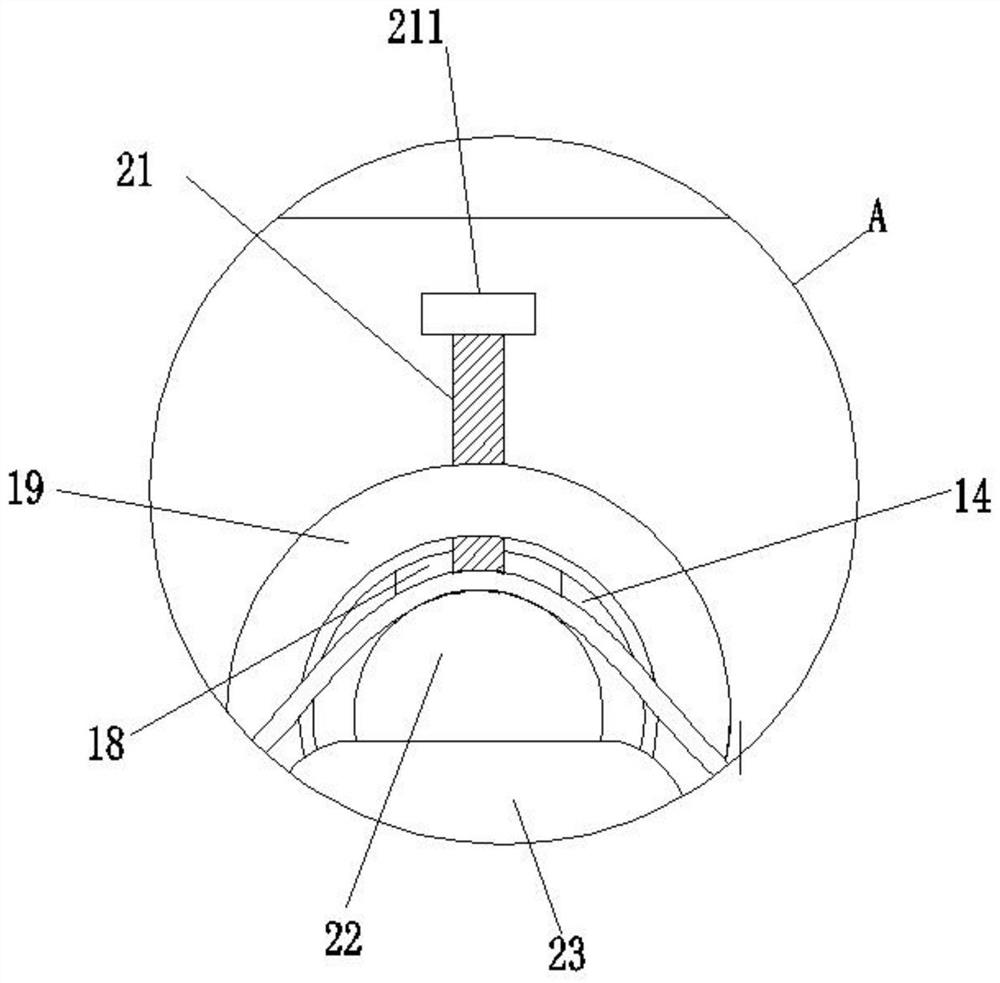

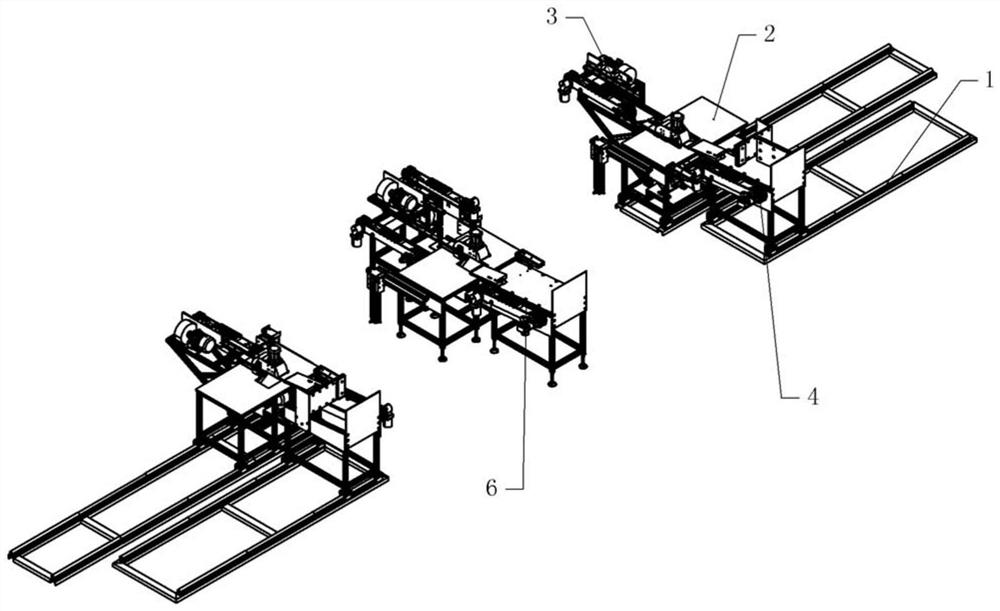

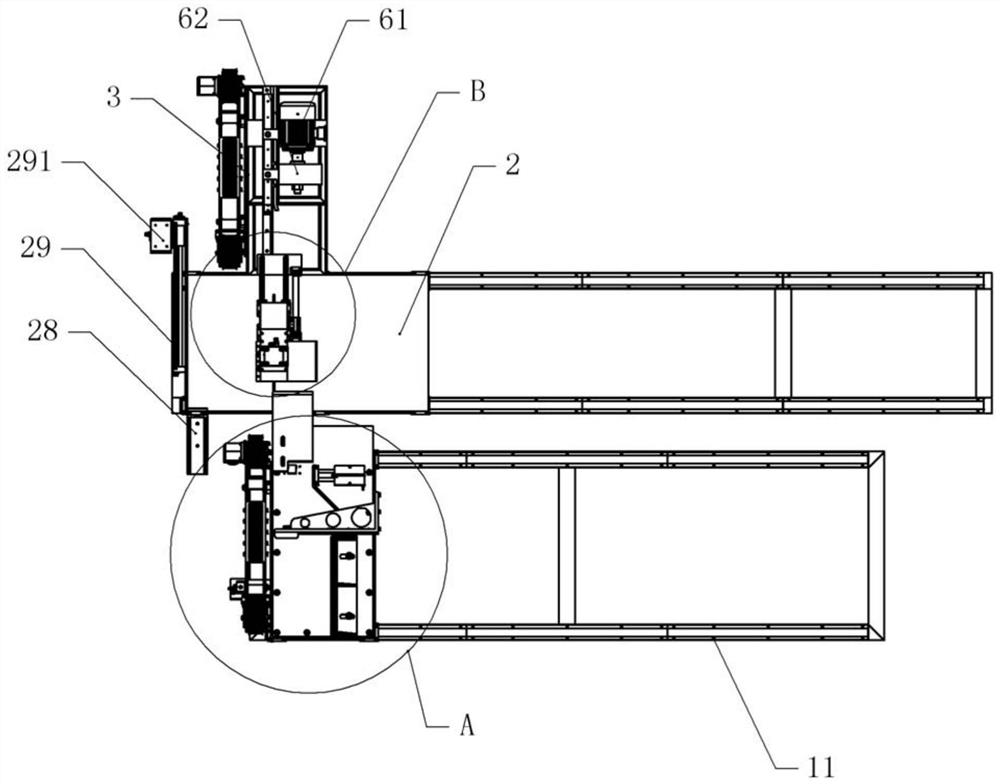

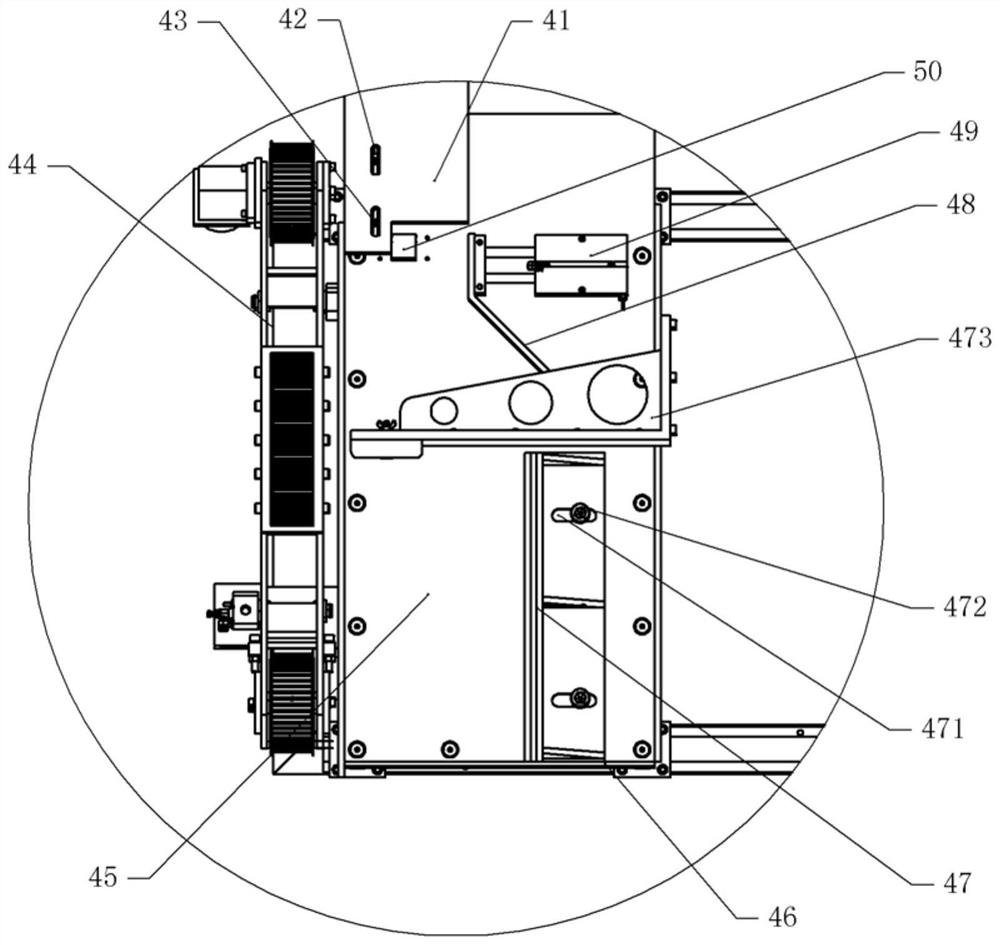

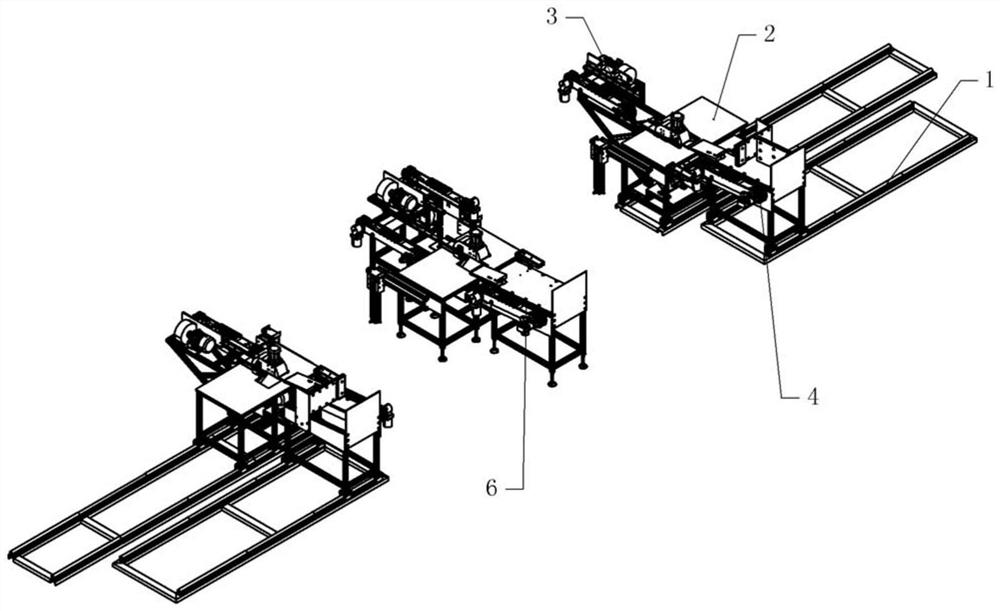

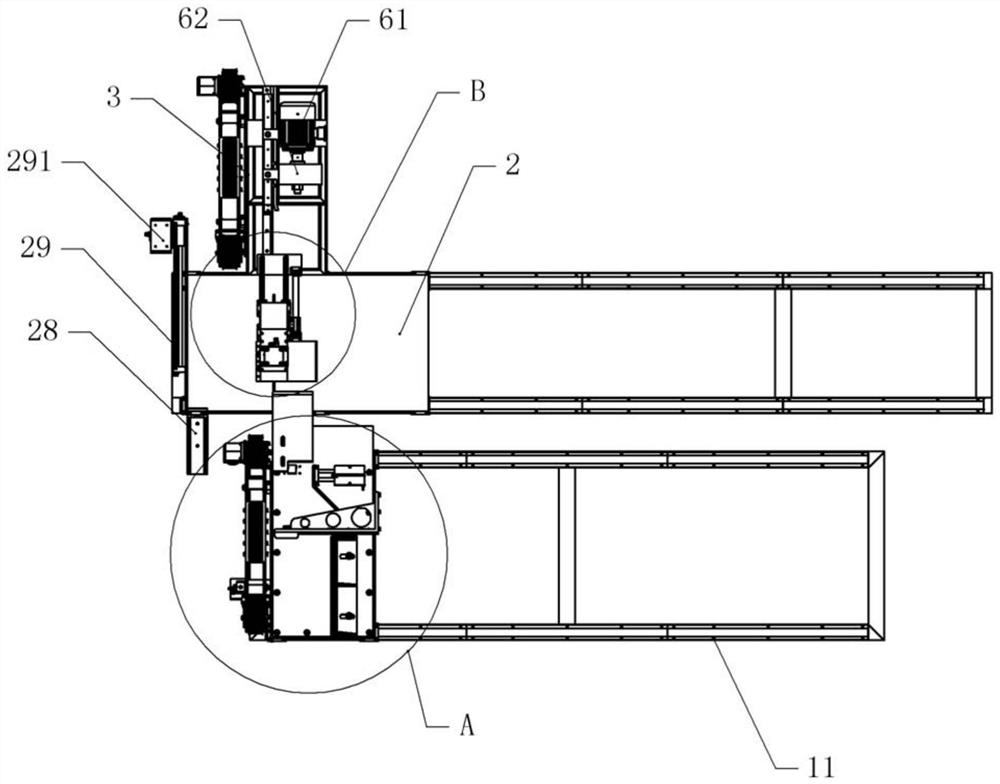

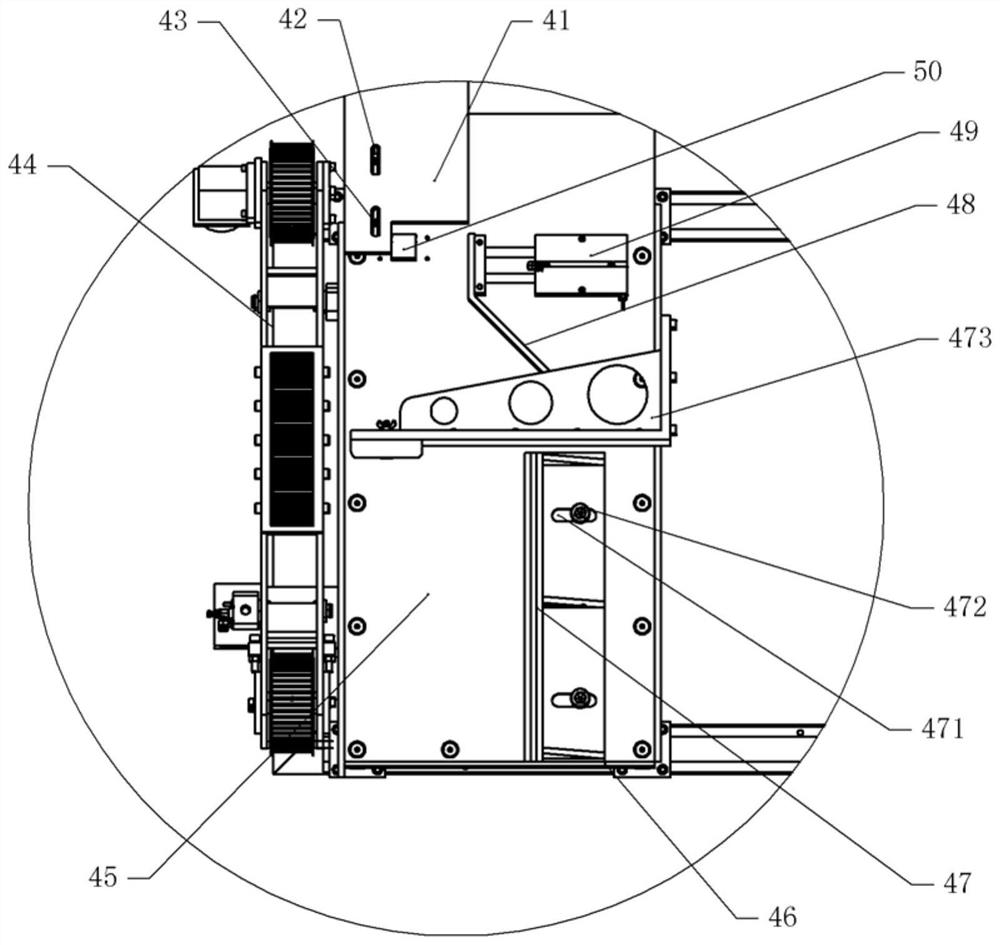

Non-woven bag making machine production line

PendingCN112677566AEasy to replaceEasy to fixBag making operationsPaper-makingProduction linePunching

The invention discloses a non-woven bag making machine production line, and belongs to the technical field of non-woven bag making machines. The non-woven bag making machine production line comprises a conveyor device, a double-color printing device, an ultrasonic embossing and punching device, a cloth synchronous conveyor device, ultrasonic left and right edge bonding devices, left and right trimming waste winding devices, a former sizing device, an ultrasonic sealing device, a transverse cutter and an operation desk. The conveyor device, the double-color printing device and the ultrasonic embossing and punching device are sequentially connected with the top of the operation desk. According to the production line, the whole device can be supported through arrangement of the operation desk, and non-woven fabric in rolls can be conveyed through arrangement of the conveyor device; double-color printing can be conducted on the non-woven fabric through the double-color printing device, and embossing and punching can be conducted on the printed non-woven fabric through the ultrasonic embossing and punching device; and then, the cloth is synchronously conveyed by the cloth synchronous conveyor device, and the left and right sides of the cloth are subjected to edge bonding treatment by the ultrasonic left and right edge bonding device.

Owner:江西德乐智能科技有限公司

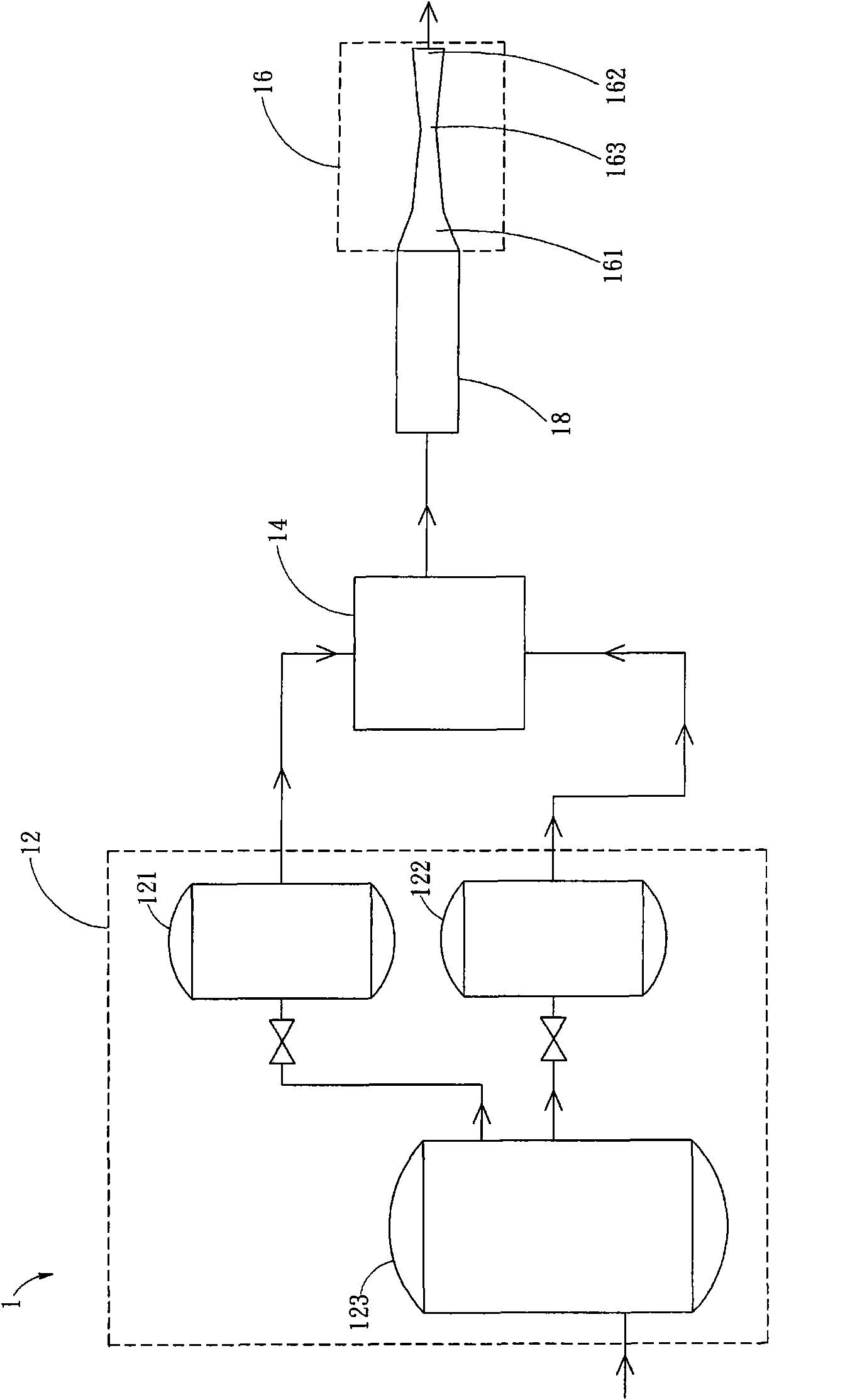

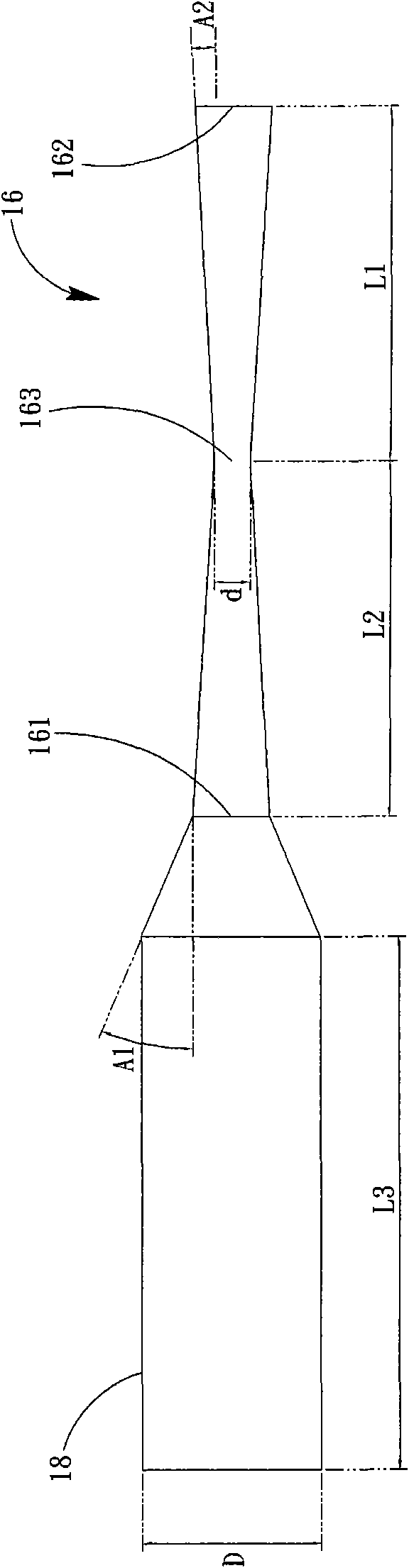

Transmission device

ActiveCN101987218AReduce harmAvoid damageIntravenous devicesOther foreign material introduction processesComputer moduleLoad carrying

The invention discloses a transmission device which is used for transmitting a substance to a target in a physical mode. The transmission device comprises an input module, a transmission module and an output module, wherein the input module is used for transmitting load carrying fluid; the transmission module is connected with the input module, internally stored with the substance and used for receiving the load carrying fluid to atomize the substance and mix the load carrying fluid with the substance; the output module is provided with a first opening and a second opening, and the caliber ofthe first opening is larger than that of the second opening; and the mixture of the substance and the load carrying fluid enters the output module through the first opening and is output from the output module through the second opening.

Owner:陈建龙

Wheat impurity removal equipment for environmental agricultural machinery

InactiveCN112317108AAvoid pollutionGuaranteed working conditionSievingScreeningAgricultural scienceGear wheel

The invention belongs to the technical field of wheat impurity removal, and relates to wheat impurity removal equipment for environmental agricultural machinery. The wheat impurity removal equipment comprises a base, a box body and a dust collection box are fixedly connected to the top of the base, a third bearing is fixedly connected to the top of the inner wall of the box body, a third rotatingshaft is arranged in the third bearing in a penetrating mode, and the top end of the third rotating shaft penetrates through the third bearing and is fixedly connected with a driving assembly. The wheat impurity removal equipment for the environmental agricultural machinery has the beneficial effects that the equipment is provided with a first filter plate and a second filter plate, filter holes of the first filter plate are higher than those of the second filter plate, and thus impurities contained in wheat can be filtered multiple times, and the impurity removal effect is guaranteed; and a first motor in the driving assembly runs to drive a driving gear and a driven gear to rotate in a meshing mode, then the purpose of driving a threaded column and a second rotating shaft to rotate can be achieved through the third rotating shaft, and the whole equipment is reasonable in structure, convenient to use and high in impurity removal efficiency.

Owner:李长松

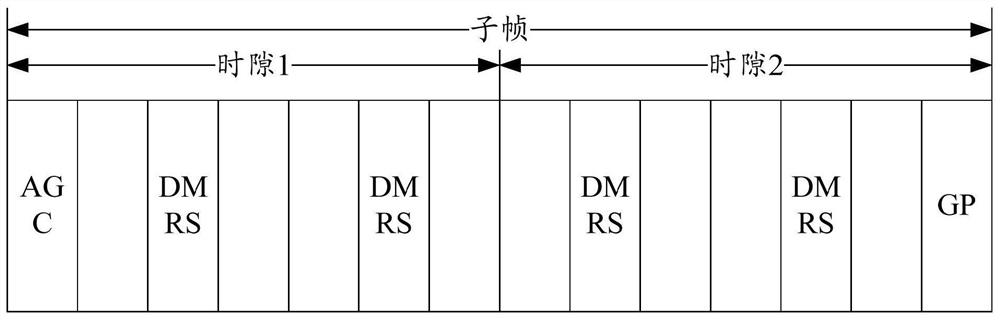

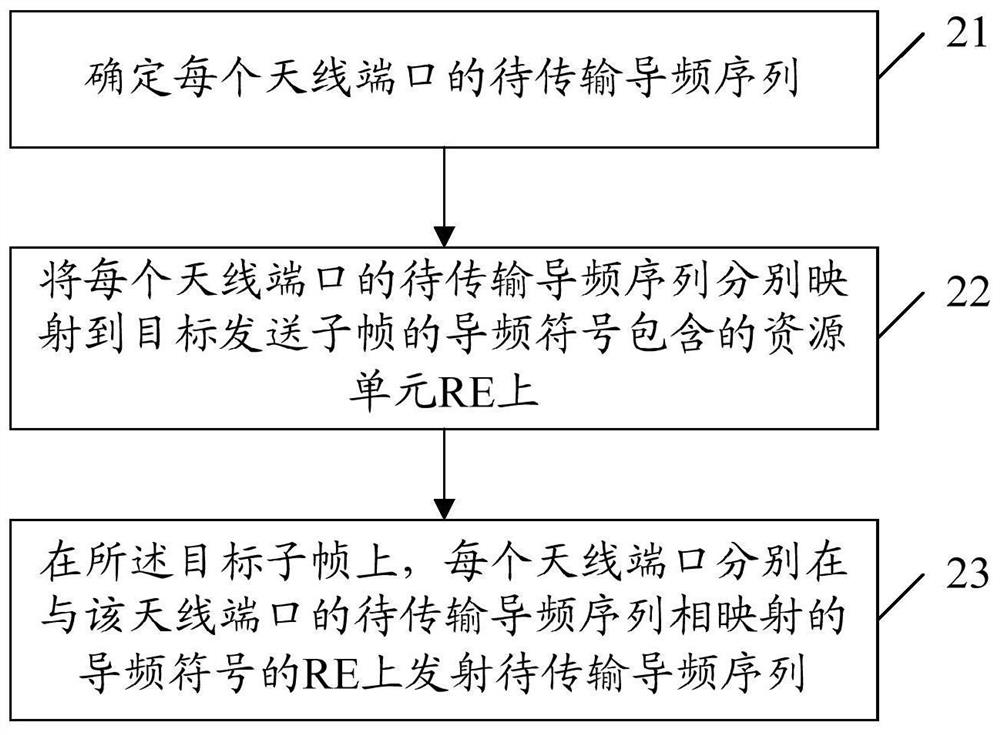

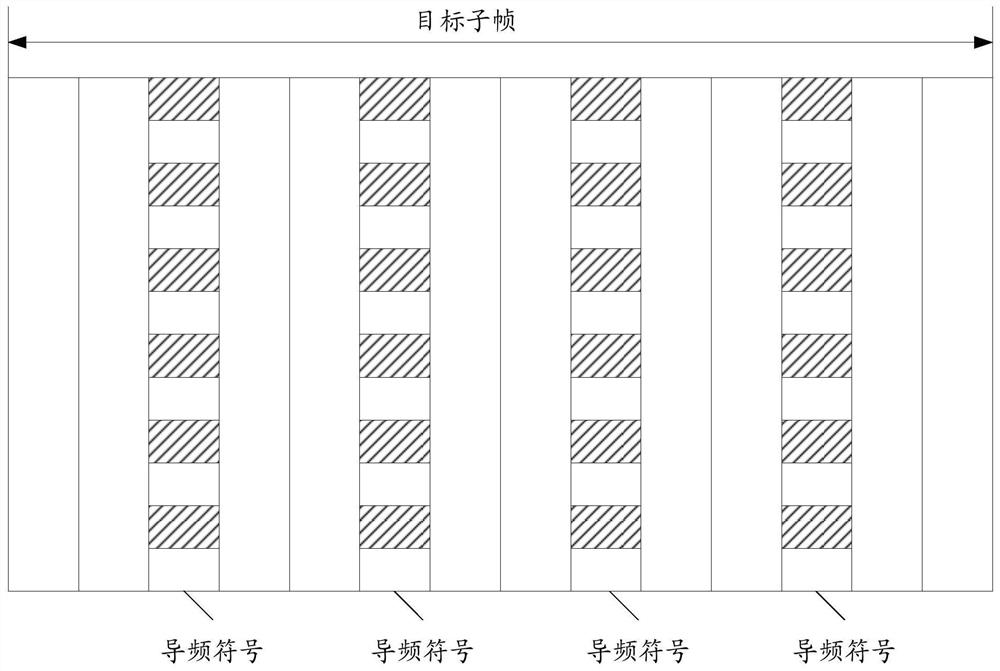

Diversity emission method and apparatus in multi-antenna communication system

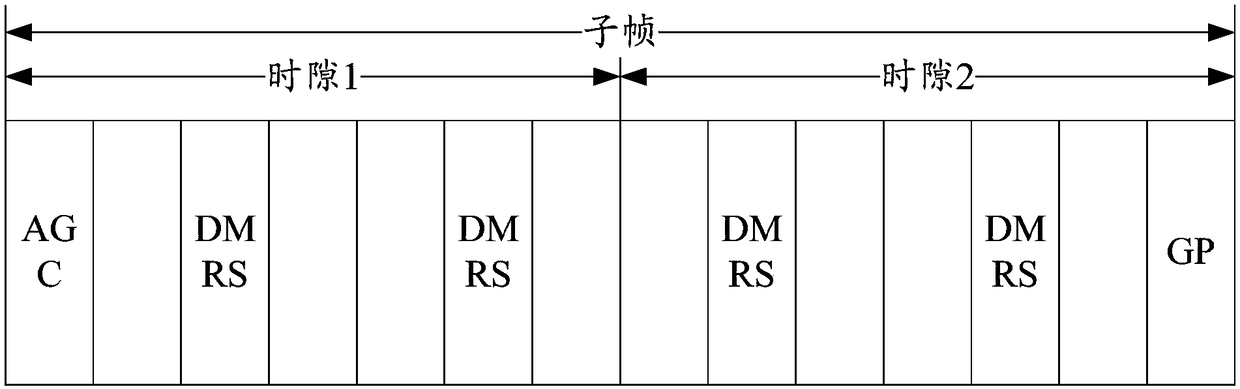

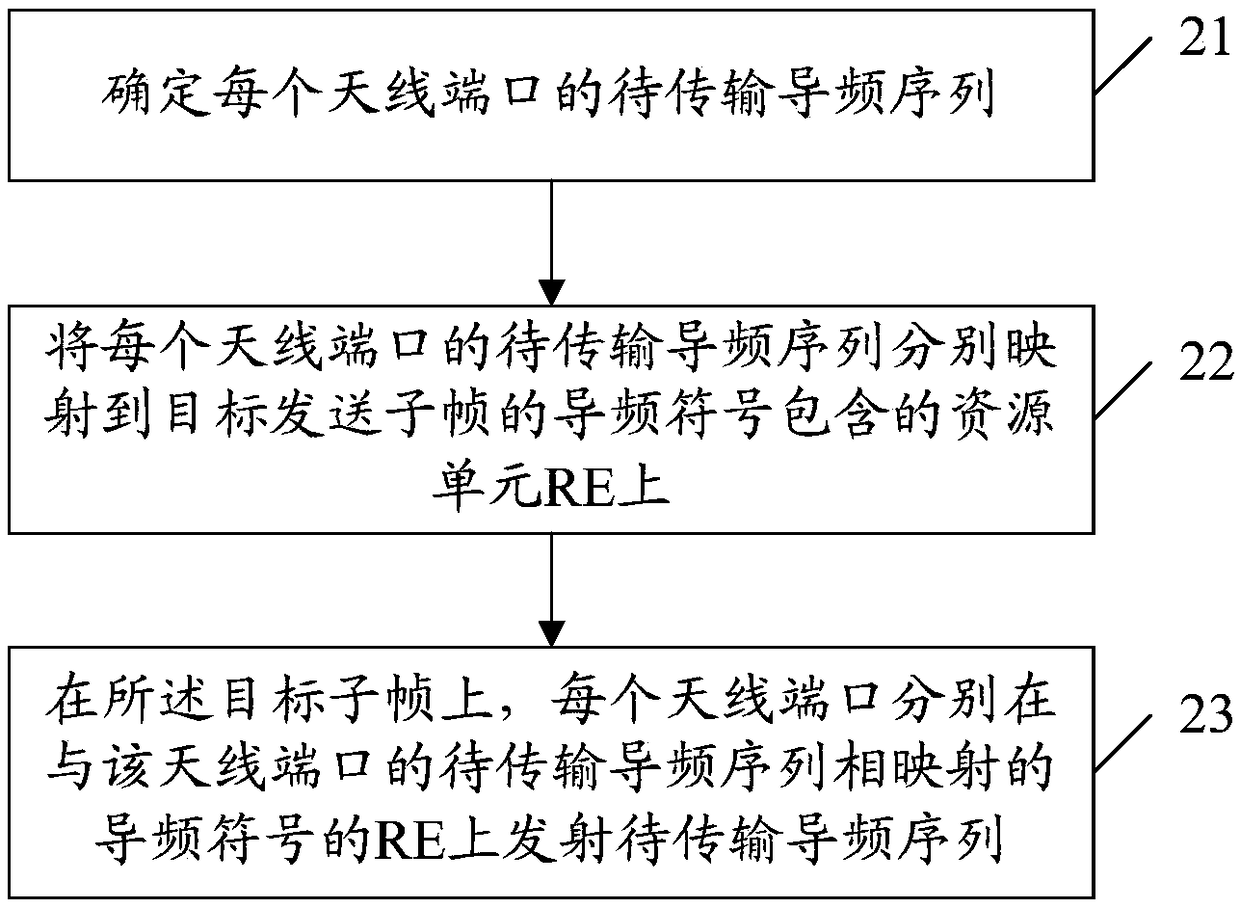

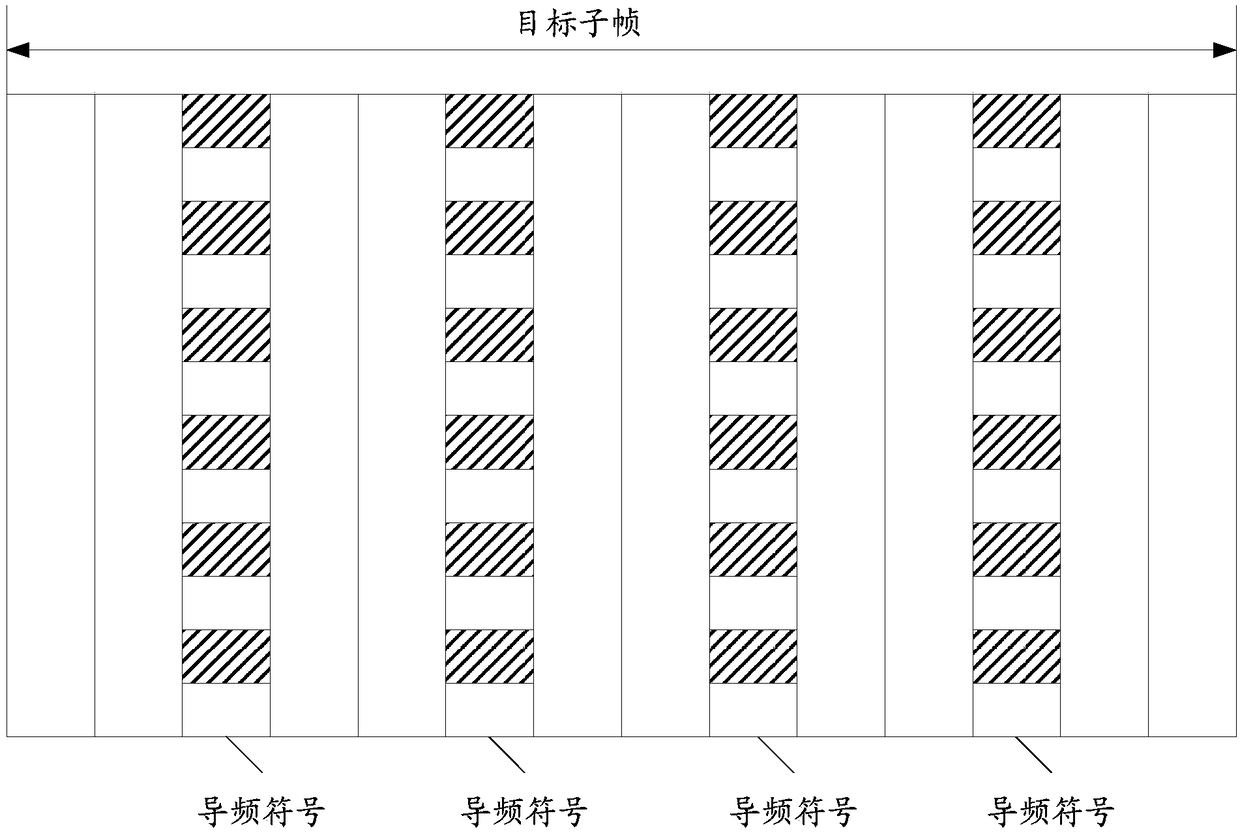

ActiveCN108631991ARealize multiplexingAchieve the purpose of transmissionPilot signal allocationError prevention/detection by diversity receptionCarrier signalTransmit diversity

The invention provides a diversity emission method and apparatus in a multi-antenna communication system. The method includes steps: determining a to-be-transmitted pilot frequency sequence of each antenna port; and respectively mapping the to-be-transmitted pilot frequency sequence of each antenna port to a resource element (RE) included by a pilot frequency symbol of a target sub-frame to enableN antenna ports reuse the pilot frequency symbol of the target sub-frame, wherein each antenna port respectively emits the to-be-transmitted pilot frequency sequences on the REs mapped to the to-be-transmitted pilot frequency sequence of the antenna port, of the pilot frequency symbol. According to embodiments of the method and apparatus, the to-be-transmitted pilot frequency sequence of each antenna port is respectively mapped to the resource element (RE) included by the pilot frequency symbol of the target sub-frame so that reuse of the pilot frequency symbol for different antenna ports isrealized; besides, the transmission of the pilot frequency sequence of each antenna port can satisfy the characteristic of a single carrier so that the goal of multi-antenna port transmission is achieved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Automatic saw cutter

ActiveCN112894383AImprove processing efficiencyEasy to processMetal sawing devicesOther manufacturing equipments/toolsStructural engineeringTransfer mechanism

The invention relates to the technical field of copper tube cutting and discloses an automatic saw cutter. The automatic saw cutter comprises a rack, wherein a first saw cutter, a second saw cutter and a third saw cutter are arranged on the rack from left to right in sequence, both the first and third saw cutters are provided with limiting platforms, a limiting groove and a first transfer mechanism for transporting a copper tube are arranged on each limiting platform, a discharge opening is formed in the side, close to the tail end, in the conveying direction, of the first transfer mechanism, of the limiting groove, a baffle plate for closing the discharge opening is vertically and slidably connected to the limiting groove, and a first adjusting assembly for adjusting a cutting position of the copper tube is arranged in any one limiting groove; second transfer mechanisms are arranged on the first saw cutter, the second saw cutter and the third saw cutter, the first and third saw cutters are both provided with first polishing mechanisms in a fit manner, and the second and third saw cutters both are provided with second polishing mechanisms in a fit manner. The automatic saw cutter is simple in structure, cuts the copper tube in multiple sections, and improves the copper tube cutting efficiency.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

Method for manufacturing edible fungus four-pipe baking oven

The invention provides a method for manufacturing an edible fungus four-pipe baking oven. A fuel inlet is formed in the lower portion of the four-pipe baking oven, a smoke exhaust port is formed in the upper portion of the four-pipe baking oven, a first arc-shaped top plate, a first side plate, a second side plate, a first bottom plate, a grate bridge and a hearth are sequentially arranged in a burning region in the four-pipe baking oven, a second arc-shaped top plate, a first bearing plate, a third side plate, a fourth side plate, a first back plate, a first pipeline type heating pipe, a second pipeline type heating pipe, a third pipeline type heating pipe and a fourth pipeline type heating pipe are sequentially arranged on a heat conducting channel in the four-pipe baking oven, a second bearing plate, a fifth side plate, a sixth side plate, a second bottom plate, a second back plate, a first sealing cover, a second sealing cover, a third sealing cover and a fourth sealing cover are sequentially arranged on a dust remover in the middle of the four-pipe baking oven, and a mask plate, a seventh side plate, an eighth side plate, a third back plate, a third bottom plate, a first supporting column, a second supporting column and a connecting screw are sequentially arranged on a smoke guide outlet in the four-pipe baking oven. The edible fungus four-pipe baking oven is economical and applicable.

Owner:CHENGDU DRAGON WATER TREATMENT TECH RES INST

Loading device used for casting mold in production process

InactiveCN114406248AIncrease productivityReach pourMould handling equipmentsManufacturing engineeringRack and pinion

The invention relates to the technical field of loading devices, in particular to a loading device used for a casting mold in the production process, and provides the following scheme that the loading device comprises a base, a supporting rod is fixedly connected to the top surface of the base, a second column is rotationally connected to one side of the supporting rod, and a mold body is fixedly connected to one end of the second column; a second rod is fixedly connected to the top face of the supporting rod, a first rod is fixedly connected to one side of the second rod, an air cylinder is fixedly connected to the bottom of the first rod, a fifth rod is fixedly connected to the extension end of the air cylinder, a cover is fixedly connected to one side of the fifth rod, and the cover is matched with the opening; the bottom of the fifth rod is fixedly connected with a third rod, the bottom end of the third rod is fixedly connected with a second rack, the outer portion of the second column is fixedly connected with a second gear, and the second gear is matched with the second rack. The purpose of avoiding consuming a large amount of manpower to take and demold the parts so as to improve the production efficiency is achieved.

Owner:ANHUI UNIV OF SCI & TECH

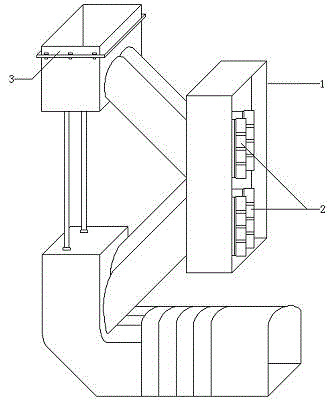

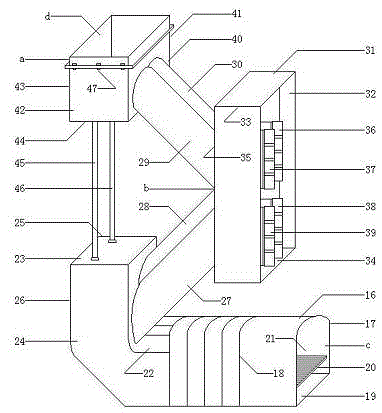

an electronic device

ActiveCN111315175BImprove reliabilityAchieve the purpose of transmissionClamping/extracting meansControl theoryMechanical engineering

The present invention provides an electronic device, comprising: a housing, a power mechanism, a rotating part, a sliding part and a driven part, and the power mechanism, the rotating part and the sliding part are all arranged in the housing; the The first end of the rotating part is connected with the power mechanism, and the surface of the rotating part is provided with a spiral slide groove; the first end of the sliding part is connected with the driven part, and the sliding part is provided with a The spiral chute is matched with the first slider; wherein, the power mechanism drives the rotating part to rotate, and drives the first slider to slide in the helical chute, so that the driven part It has a first state protruding from the housing and a second state being accommodated in the housing. In the embodiment of the present invention, the rotating part and the sliding part work together to achieve the purpose of transmission, and the rotating part and the sliding part have a better effect of resisting external impact force, thereby enhancing the reliability of driving the driven part.

Owner:VIVO MOBILE COMM HANGZHOU CO LTD

Data transmission method and device

ActiveCN108628683BAchieve the purpose of transmissionImprove transmission efficiencyInterprogram communicationTransmissionData transmissionReal-time computing

The invention discloses a data transmission method and device. Wherein, the method includes: receiving the first request sent by the first target object; sending a first response message to the first target object in response to the first request, and transmitting the first target data to the second target object through the network, and the first response message Used to simulate the response message sent by the second target object after receiving the first target data; receive the second request sent by the first target object in response to the first response message, and the second request is used to request transmission to the second target object through the network Second target data for remote debugging; sending a second response message to the first target object in response to the second request, and transmitting the second target data to the second target object through the network, wherein the second response message is used to simulate the first target object The response message sent by the second target object after receiving the second target data. The invention solves the technical problem of low transmission efficiency of data transmission in the related art.

Owner:TENCENT TECH (SHENZHEN) CO LTD

A method and device for transmitting diversity in a multi-antenna communication system

ActiveCN108631991BRealize multiplexingAchieve the purpose of transmissionPilot signal allocationError prevention/detection by diversity receptionCommunications systemResource element

Provided by the present disclosure are a method and apparatus for transmitting diversity in a multi-antenna communication system, the method comprising: determining a pilot frequency sequence to be transmitted of each antenna port; mapping the pilot frequency sequence to be transmitted of each antenna port respectively to a resource element (RE) comprised in a pilot frequency symbol of a target subframe, so that the N antenna ports multiplex the pilot frequency symbol of the target subframe; on the target subframe, each antenna port respectively transmitting the pilot frequency sequence to be transmitted on the RE of the pilot frequency symbol to which the pilot frequency sequence to be transmitted of the antenna port is mapped.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Suspending type track material conveying system

InactiveCN110422577AThere will be no danger of fallingAchieve the purpose of transmissionMechanical conveyorsEngineeringMechanical engineering

The invention discloses a suspending type track material conveying system which comprises a shell assembly, a track and a moving assembly. The shell assembly comprises a box. Through grooves are symmetrically formed in the bottom of the box. The track is welded to the inner side wall of the box. The moving assembly comprises a first plate body and second plate bodies. The second plate bodies are symmetrically welded to the top of the first plate body. Fixing blocks are welded to the opposite sides of the two second plate bodies. When a user uses the system, materials are placed into a materialbox, four clamping devices work to fix the material box to the box, then an electric pushing rod is controlled, thus the material box is guided into the box, at the moment, a first motor is controlled to work, thus a limiting wheel moves on the track, the purpose of conveying the material box is achieved, in the conveying process, conveying of the materials is not interfered by moving of personnel, and due to arrangement of the box, the situation that in the material conveying process, the materials fall off, and danger is caused can be prevented.

Owner:苏州旗开得电子科技有限公司

Fixed-length detection discharging device for filter bag cutoff

PendingCN110936425AAchieve the purpose of transmissionPrevent deviationMetal working apparatusElectric machineTransmission belt

The invention discloses a fixed-length detection discharging device for filter bag cutoff and relates to the technical field of fixed-length detection discharging devices. The fixed-length detection discharging device comprises a base. A first motor and a fixing plate are fixedly connected to the top of the base. A pressing wheel and a first transmission wheel are movably connected in the fixing plate. A first conveyor belt is movably connected to one side of the first transmission wheel. The end, away from the first transmission wheel, of the first conveyor belt is movably connected with theoutput end of the first motor. A workbench is fixedly connected to the top of the base, and the workbench is located on the right side of the fixed plate. According to the fixed-length detection discharging device for filter bag cutoff, by arranging a sensitive switch, the purpose of stopping a transmission device in time is achieved; and through the matching arrangement between a driving motor, ascrew rod, an electric telescopic rod and a scale plate, the purpose of accurately adjusting the cutoff length of a filter bag is achieved.

Owner:苏州海蓝环保科技有限公司

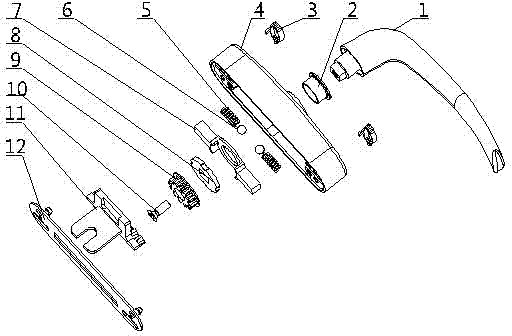

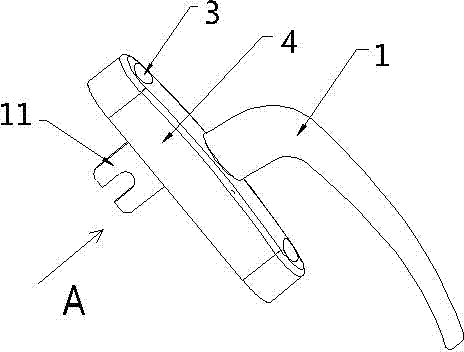

Aluminum alloy handle for doors and windows

InactiveCN103410379BAchieve closureAchieve the purpose of transmissionWing handlesWing knobsAlloyMaterials science

The invention relates to the field of accessories for door windows, in particular to an aluminum alloy handle for door windows. The aluminum alloy handle is characterized in that a shaft sleeve and a handle seat of the aluminum alloy handle are assembled together, and a handle is penetratingly arranged in a hole of the shaft sleeve; springs are placed in a lining plate, then balls are placed in holes of the springs, the springs and the lining plate are assembled together and then are placed into the handle seat, then a gasket is assembled on the lining plate and is assembled on the other side of the handle seat, a gear is placed on the gasket, the handle seat and the handle are fixed to each other by the aid of a cross recessed countersunk head screw, a shift fork is placed into the handle seat and is meshed with the gear, mounting holes which are perforated through the handle seat are formed in the upper surface of the handle seat, threaded holes are formed in the lower surface of the handle seat, a bottom cover is fastened in the holes of the handle seat, and the mounting holes and the threaded holes can be exposed via the bottom cover. Assorted fastening covers are arranged on the mounting holes. The aluminum alloy handle has the advantages that the aluminum alloy handle not only can be applied to outward-opening windows, but also can be applied to inward-opening windows, only a large quantity of handles with identical specifications need to be prepared when assembled, and cannot be mixed up, and accordingly the practical performance of the aluminum alloy handle is improved.

Owner:ASSA ABLOY GUOQIANG SHANDONG HARDWARE TECH CO LTD

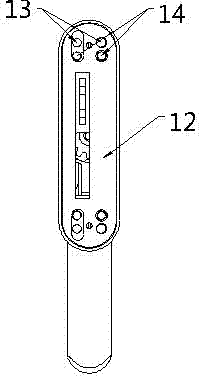

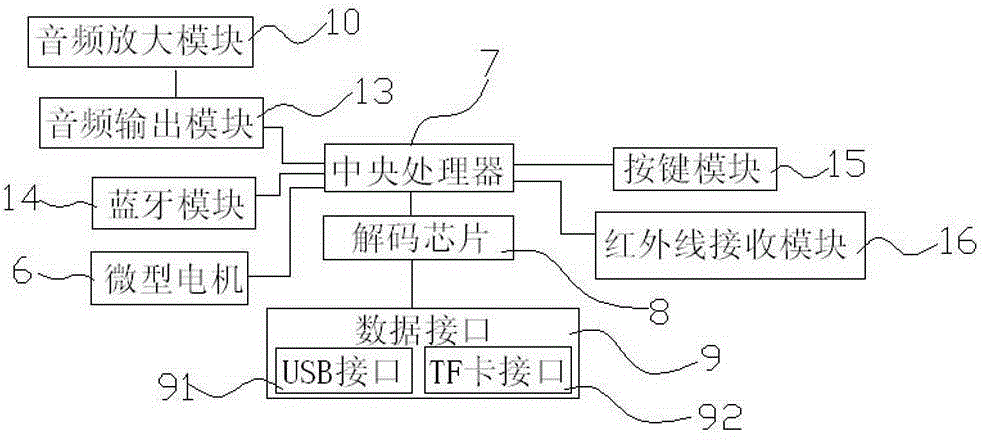

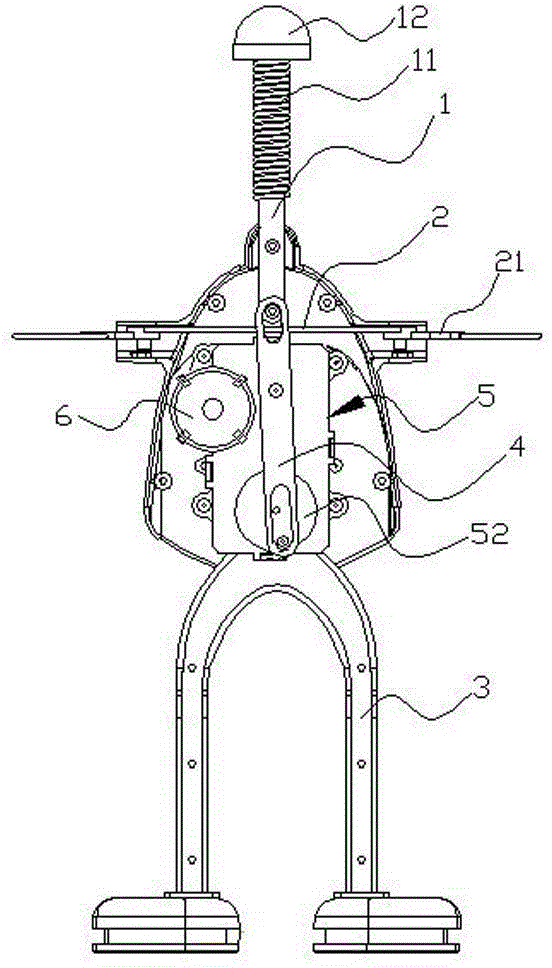

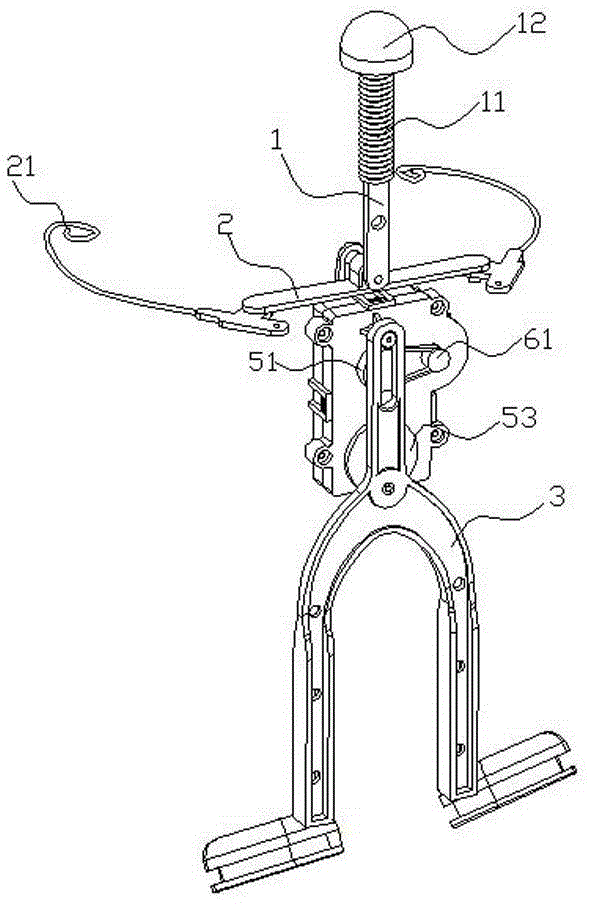

Toy movement and dancer toy manufactured thereby

InactiveCN105363212ASimple structureEnhance interestSelf-moving toy figuresToy gearsData informationLinkage concept

The invention discloses a toy movement, comprising: a data interface, receiving a data source input by a user; a decoding chip, receiving the data source of the data interface and decoding and outputting data information; a central processing unit, receiving and processing the data information output by the decoding chip and outputting a control signal; a miniature motor, outputting power to drive a main linkage shaft of a toy according to the control signal output by the central processing unit. A toy manufactured based on the toy movement comprises a main linkage shaft, a top linkage shaft, arm linkage shafts, a leg frame, and a gear box, the lower end of the top linkage shaft is movably connected with the top end of the main linkage shaft, and the middles of the arm linkage shafts are movably connected with the top end of the main linkage shaft, and the arm linkage shafts are perpendicular to the main linkage shaft. The toy allows data to be transmitted through the data interface and also through Bluetooth; upon startup of the toy, the toy can be remotely controlled directly through a remote control in addition to being operated through keys.

Owner:任思洪

Automatic sawing machine

ActiveCN112894383BImprove processing efficiencyEasy to processMetal sawing devicesOther manufacturing equipments/toolsStructural engineeringIndustrial engineering

The invention relates to the technical field of copper pipe cutting, and discloses an automatic sawing machine, which includes a frame on which a first sawing machine, a second sawing machine and a third sawing machine are sequentially arranged from left to right, Both the first sawing machine and the third sawing machine are equipped with a limit platform, and the limit platform is equipped with a limit groove and a first transmission mechanism for transporting copper pipes, and the limit groove is close to the side of the end of the first transmission mechanism in the conveying direction There is a discharge port, a baffle plate for closing the discharge port is vertically slidably connected to the limit slot, and a first adjustment component for adjusting the cutting position of the copper pipe is arranged in any limit slot; the first sawing machine, The second sawing machine and the third sawing machine are provided with a second transmission mechanism, the first sawing machine and the second sawing machine are provided with a matching first grinding mechanism, and the second sawing machine and the third sawing machine are provided with a second transmission mechanism. Both are provided with a matching second grinding mechanism. The invention has a simple structure, and is used for multi-section cutting of the copper pipe to improve the cutting efficiency of the copper pipe.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

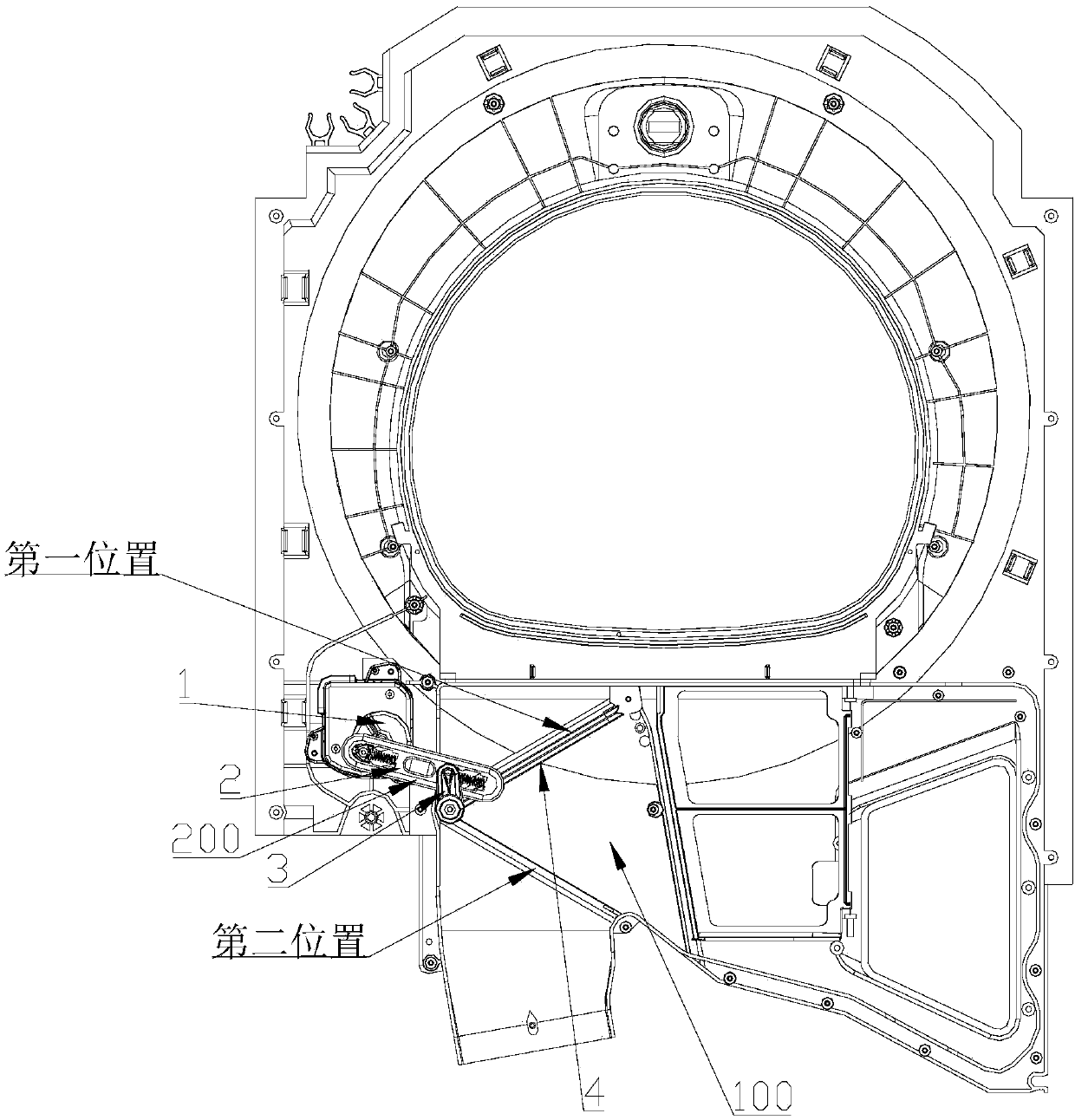

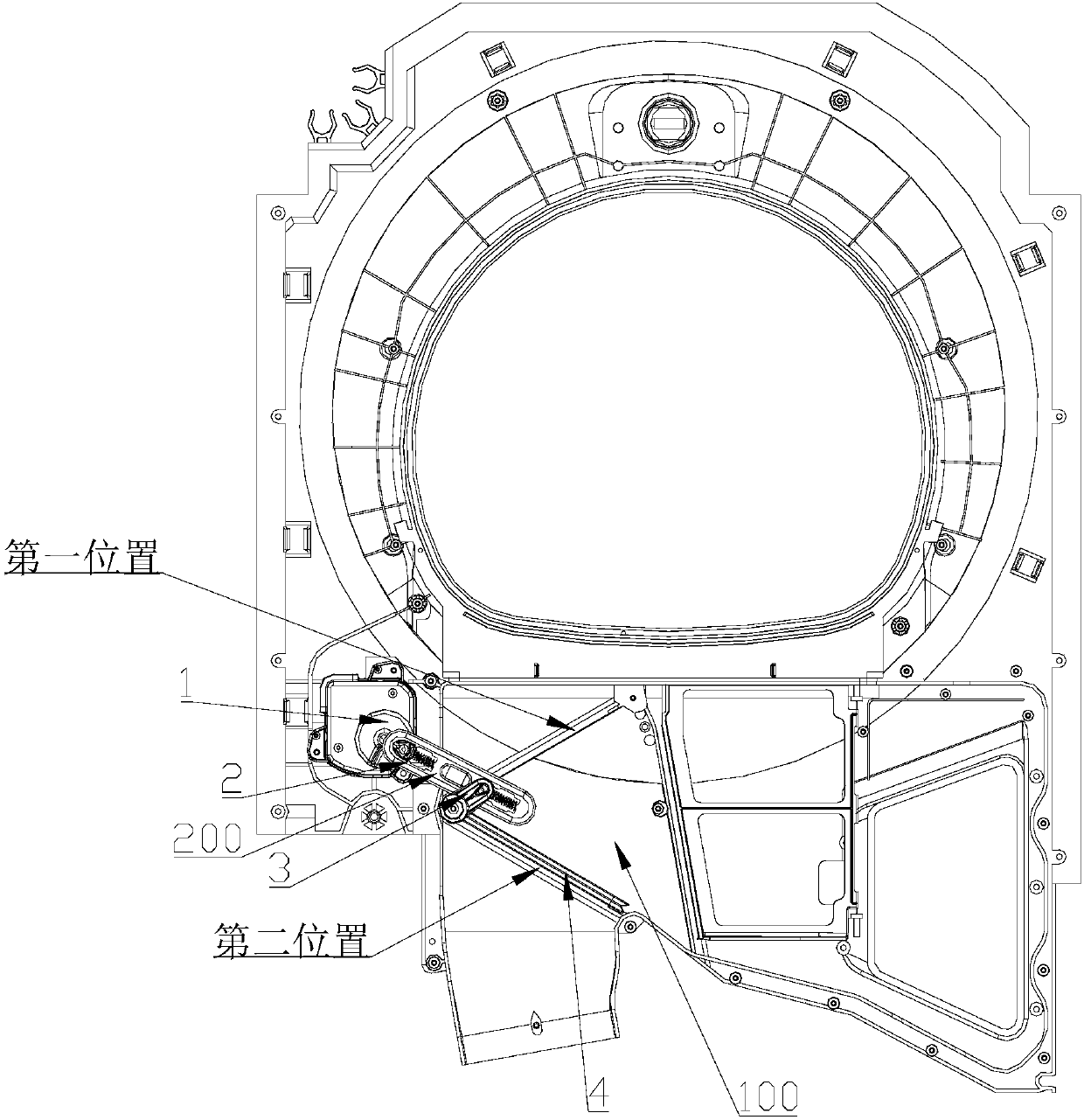

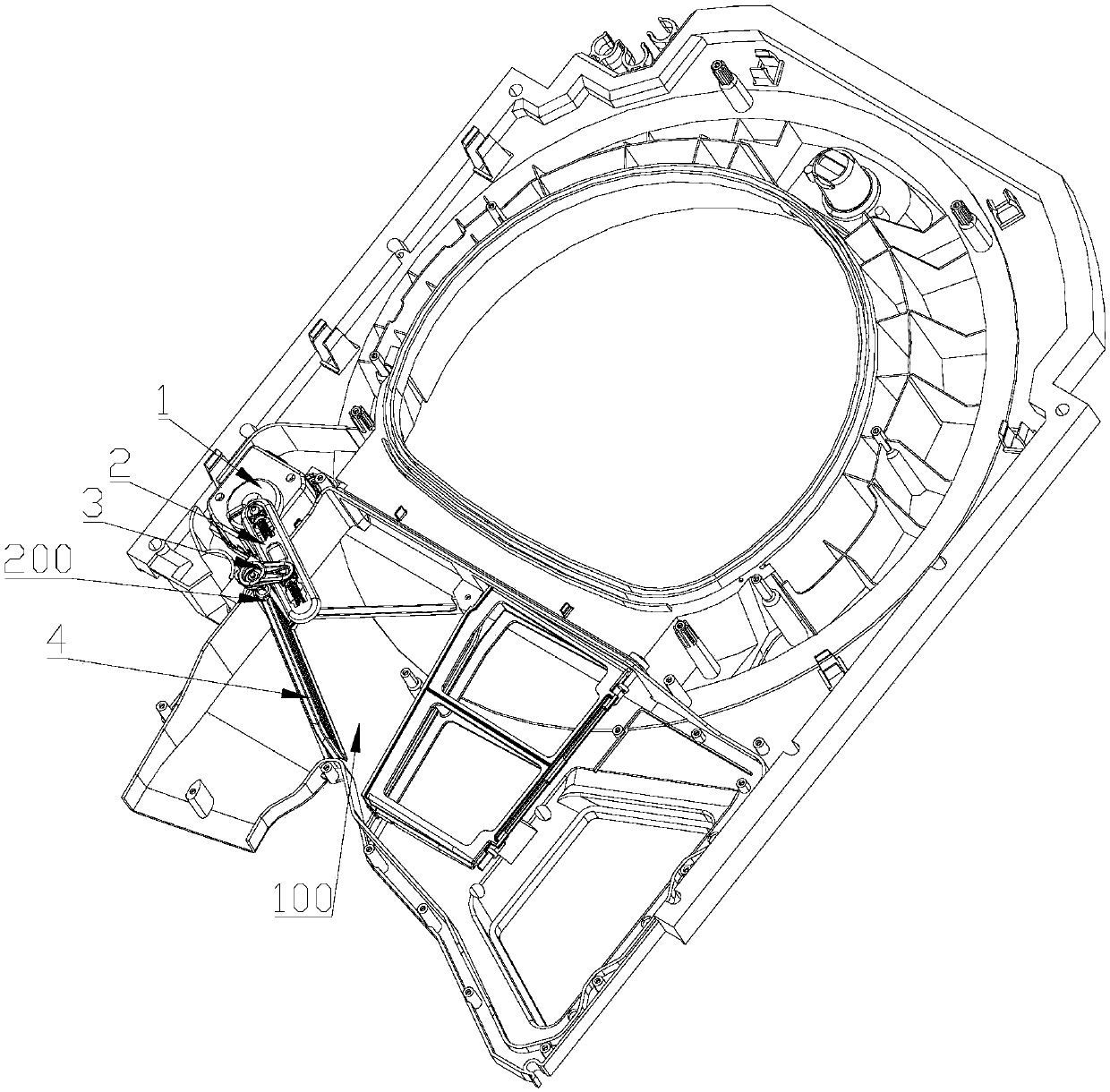

Air channel switching device adaptor and air channel switching device

PendingCN110107696AAchieve the purpose of transmissionShorten the path of movementOperating means/releasing devices for valvesWashing machine with receptaclesEngineeringElectrical and Electronics engineering

The invention discloses an air channel switching device adaptor. An adaption shaft and an adaption sleeve are respectively arranged at two ends of the adaptor; the adaption shaft is connected with a connection cross beam of the air channel switching device in a manner of rotating around the shaft; the adaption sleeve is fixedly connected with an air channel baffle of the air channel switching device in a manner of not rotating relative to each other. The invention also discloses an air channel switching device. The air channel switching device comprises an air channel baffle mounted on an airchannel in a manner of relatively rotating; a motor output shaft is connected with the air channel baffle through a linkage mechanism; the linkage mechanism drives the air channel baffle to rotate around the shaft in a rotation process of the motor output shaft, so that the air channel baffle is switched and moved between a first position and a second position; the linkage mechanism comprises theair channel switching device adaptor. According to the air channel switching device adaptor, the adaptor is additionally mounted on the air channel switching device, so that the connection cross beamis capable of driving the adaptor to generate a large-range rotation angle by only swinging to a small-range angle; the rotation angle of the air channel baffle is ensured; and the purpose of reducingthe movement path of the air channel switching device is achieved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

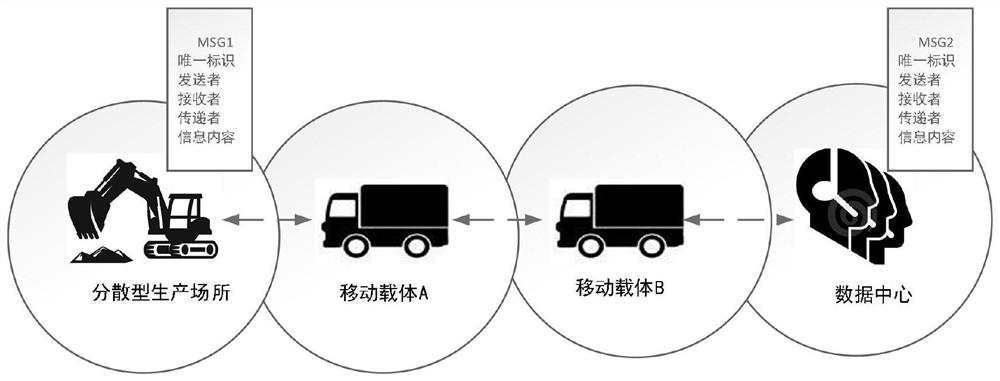

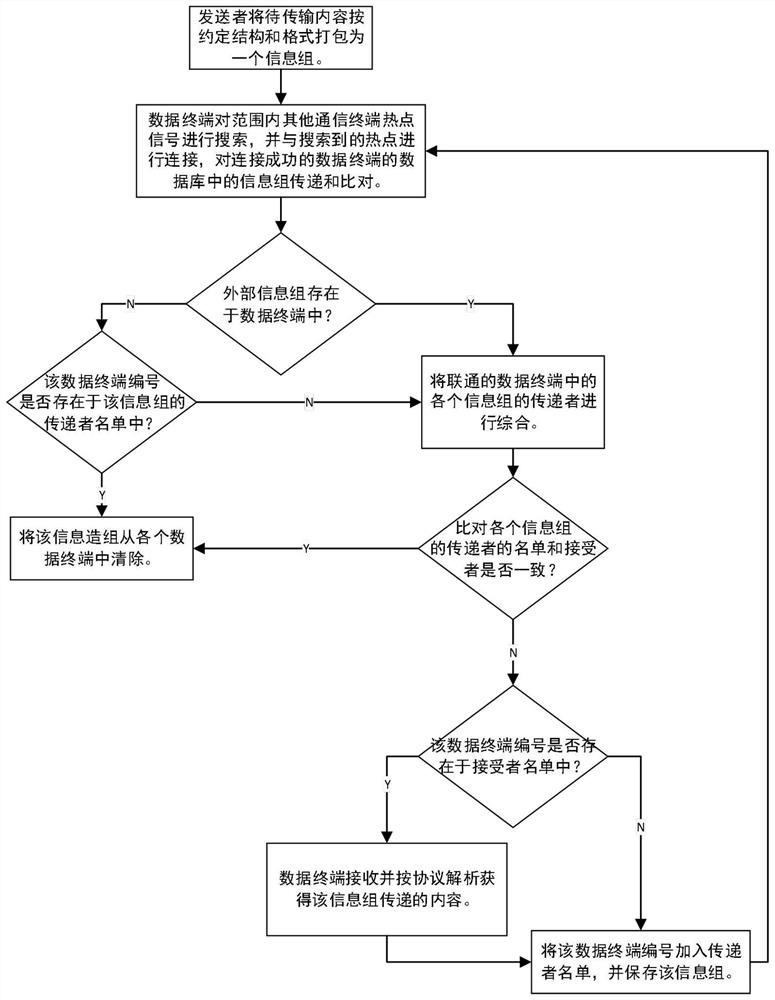

a data transfer method

ActiveCN109873798BLow costAchieve the purpose of transmissionTransmissionData terminalProcess engineering

The present invention relates to the field of computer communication, in particular to a data structure, a transmission method and a data terminal device. The terminal device on a mobile carrier realizes information reception, processing, storage and transmission, and provides time-sensitive distributed production sites. A low-cost, high-efficiency information transfer method, and in animal and plant conservation, provides an efficient collection method for relevant information. In the process of moving the carrier between the decentralized production sites, the data terminal on the mobile carrier realizes the transmission of data between the terminal devices on the mobile carrier through broadcasting, further achieving the purpose of information transmission between the decentralized production sites; in addition, During the transfer process, rules will be judged on the transfer content, and the transferred information content will be cleared in a timely manner to avoid the waste of resources such as storage, judgment and calculation due to the accumulation of a large amount of transfer information.

Owner:CHINA NONFERROUS METAL CHANGSHA SURVEY & DESIGN INST CO LTD

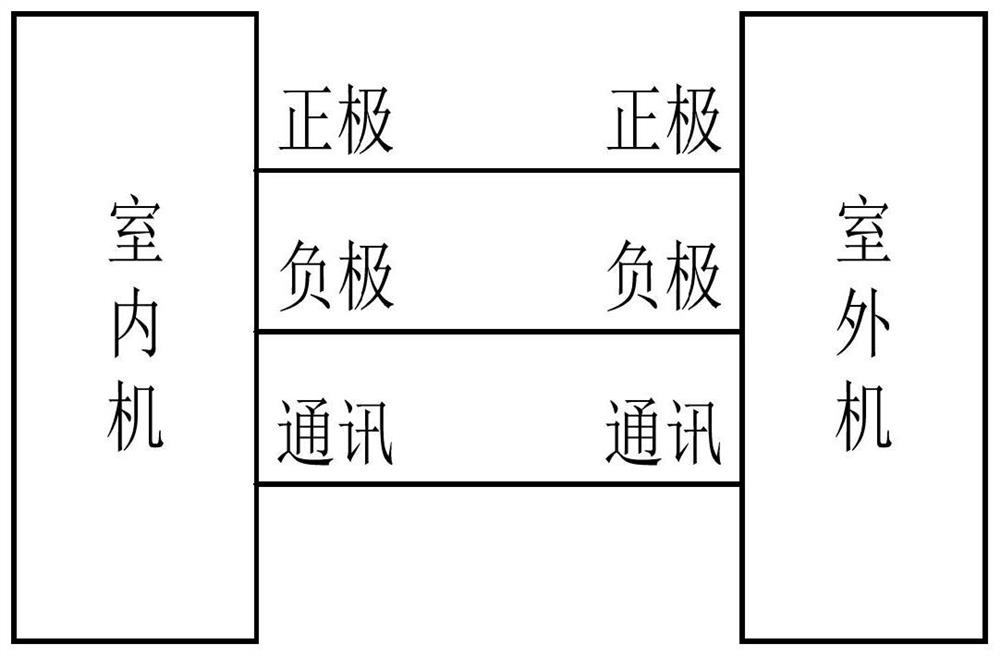

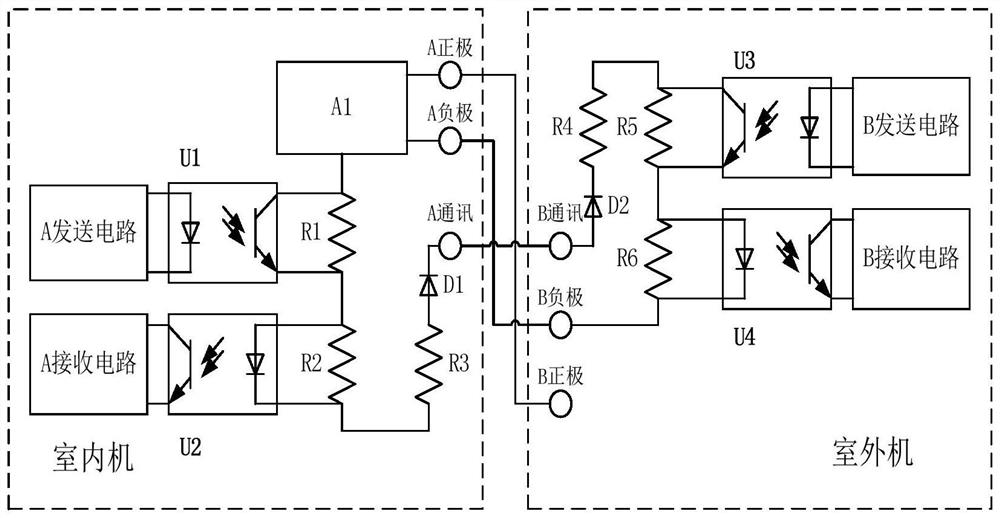

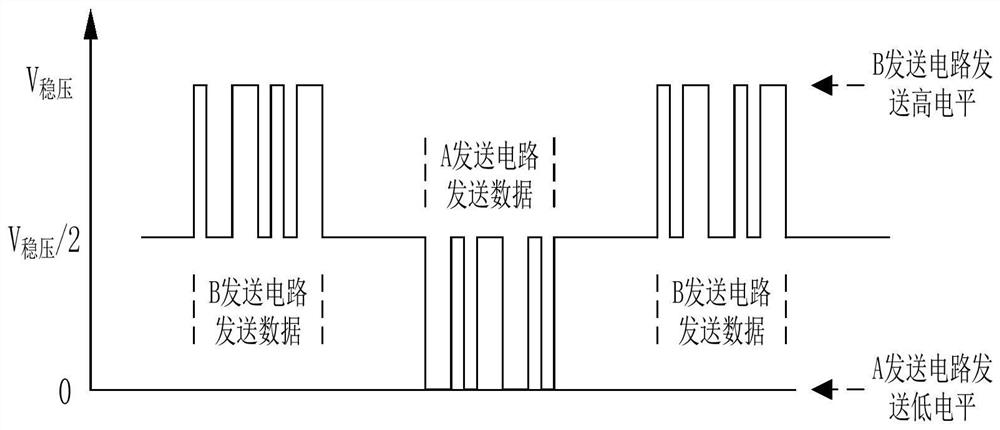

A data transmission method and communication device for a vehicle air-conditioning system

ActiveCN112140837BMeeting Communication NeedsSimple system structureAir-treating devicesVehicle heating/cooling devicesControl engineeringElectrical connection

The present application relates to a data transmission method and communication equipment for a vehicle air-conditioning system, wherein the communication equipment is applied to the first communication circuit of one of the indoor unit and the outdoor unit, and is applied to the other of the indoor unit and the outdoor unit. The second communication circuit; the positive pole of the first communication circuit is electrically connected to the positive pole of the second communication circuit; the negative pole of the first communication circuit is electrically connected to the negative pole of the second communication circuit; the communication end of the first communication circuit is connected to the second communication circuit Communication terminal communication connection. The application solves the technical problem that the communication cost of the internal and external units of the vehicle air conditioner is relatively high.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com