Method for manufacturing edible fungus four-pipe baking oven

A baking oven and edible fungus technology, applied in the fields of application, food processing, food science, etc., to achieve high drying output, remarkable effect, and unique appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

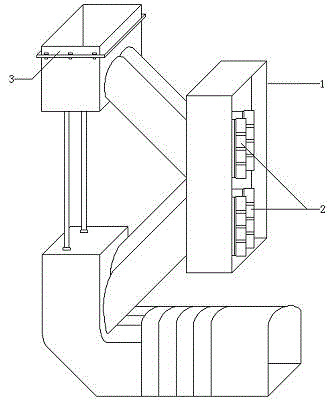

[0012] figure 1 The situation of the four-tube baking oven device of the present invention is shown, as for the use of edible fungi growers and edible fungus production enterprises, first the device 1 of the present invention is placed in a suitable position, and then the sealing cover 2 on the dust collector is placed Install it, and install the external chimney 3 at the same time and it can be used normally.

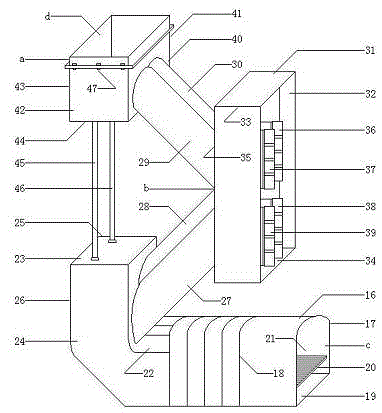

[0013] figure 2 Among them, the four-tube oven device is composed of an oven b and an external chimney a, and the oven b and an external chimney a are connected by sets of screws. The lower part of the four-tube oven is provided with a fuel inlet c, The upper part is provided with a flue gas outlet d, and the combustion zone in the four-tube oven is provided with a first arc-shaped top plate 16, a first side plate 17, a second side plate 18, a first bottom plate 19 and a furnace bridge 20 and Furnace hall 21, the heat conduction channel in the four-tube baking furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com