Optical fiber coating system and coated optical fiber

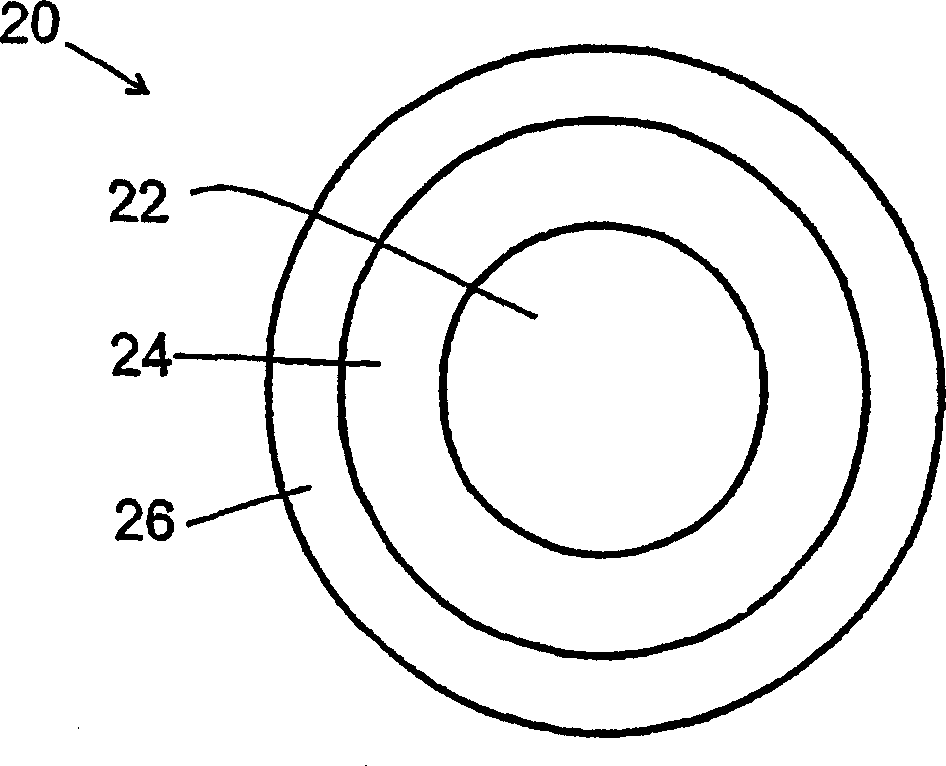

一种光纤涂层、体系的技术,应用在玻璃光纤、包层光纤、光学等方向,能够解决微弯曲损失提供足够的保护等问题,达到改善易加工性、高断裂韧度、低微弯曲损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] Primary curable compositions 1-7 were formulated with a high speed mixer in a suitable vessel heated to 70°C with a heating wire or heating mantle. In all cases, the components were weighed into containers using a scale and mixed until the solid components were completely dissolved and the mixture appeared homogeneous. The curable composition is formulated so that the sum of the amounts of oligomer, monomer and photoinitiator is 100% by weight; other additives such as antioxidant are added to the total mixture in units of parts per 100 parts. BR3741 is an oligomer available from Bomar Specialties. PHOTOMER 4003 is a monomer available from Cognis. TONE M-100 is a monomer available from Dow Chemical. IRGACURE 819 and IRGACURE 184 are photoinitiators available from Ciba Specialty Chemical. (3-propenyloxypropyl)trimethoxysilane is an adhesion promoter available from Gelest. IRGANOX 1035 is an antioxidant available from Ciba. Pentaerythritol tetrakis(3-mercaptopropionat...

Embodiment 2

[0113] Secondary curable compositions 8-9 were formulated in jacketed beakers heated to 70°C using a high speed mixer. In all cases, the components were weighed into jacketed beakers using a balance and mixed until the solid components were completely dissolved and the mixture appeared homogeneous. The curable composition is formulated so that the sum of the amounts of oligomer, monomer and photoinitiator is 100% by weight; other additives such as antioxidant are added to the total mixture in units of parts per 100 parts. KWS 4131 is an oligomer available from Bomar Specialties. PHOTOMER 4028 and PHOTOMER 3016 are monomers available from Cognis. LUCIRIN TPO is a photoinitiator available from BASF. The components used to formulate secondary curable compositions 8-9 are detailed in Table 4 below.

[0114] secondary curable composition

components

8

9

KWS 4131 (weight%)

10

10

PHOTOMER 4028 (weight%)

82

82

...

Embodiment 3

[0118] By coating a large effective area optical fiber (LEAF) with a coating system of the present invention comprising a primary coating 1 and a secondary coating 8 , purchased from Corning Corporation) to prepare coated optical fibers 1 and 2. The results of the scalable drum microbending test are given in Table 6. LEAF coated with conventional coating system Optical fibers typically have values greater than 1.4 dB / km / % strain in the scalable drum test and at 1550 nm.

[0119]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com