Control system and control method of electronic gun crucible positioning

A positioning control, electron gun technology, applied in sequence/logic controller program control, electrical program control, control using feedback, etc., can solve the problem of increased scrap rate, inability to find and deal with crucible cards, affecting production, etc. , to avoid production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

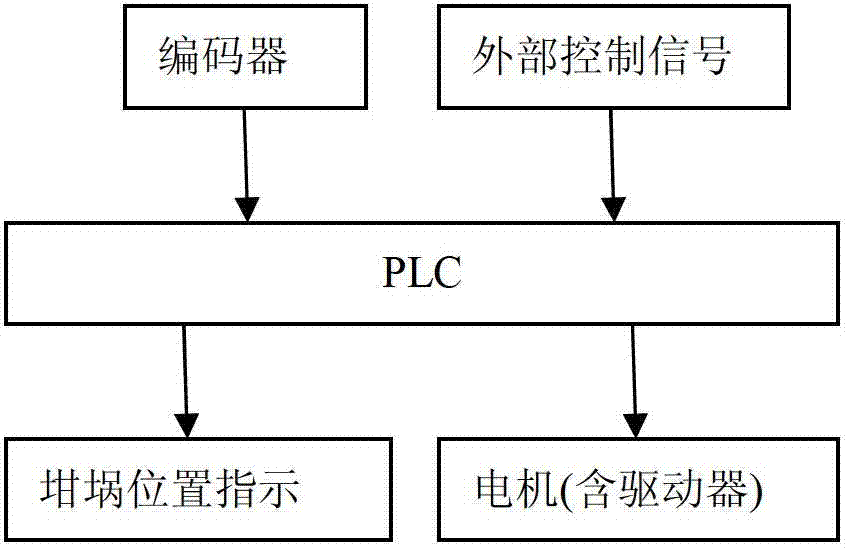

[0029] Such as figure 1 As shown, a kind of electronic gun crucible positioning control system of the present invention comprises PLC, encoder, stepper motor (including driver), wherein: PLC is the main control component, and its input end receives encoder position signal and external crucible control signal, and output end Connect the motor driver to control the stepping motor; the encoder will be the detection device, responsible for feeding back the crucible position information to the PLC; the external crucible control signal is a switch control signal, used to select the crucible; the motor is a stepping motor, AC servo motor, AC The reduction motor drives the crucible to rotate.

[0030] An encoder is a device for measuring angular displacement, which can convert angular displacement into a periodic electrical signal (pulse). The number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com