Temperature sensing plate of laminating machine

A technology of pressing machine sense and temperature sensing plate, applied in thermometers, thermometers using electric/magnetic elements directly sensitive to heat, using electromagnetic means, etc., can solve problems such as time-consuming and labor-intensive, and achieve the goal of saving procedures and working hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

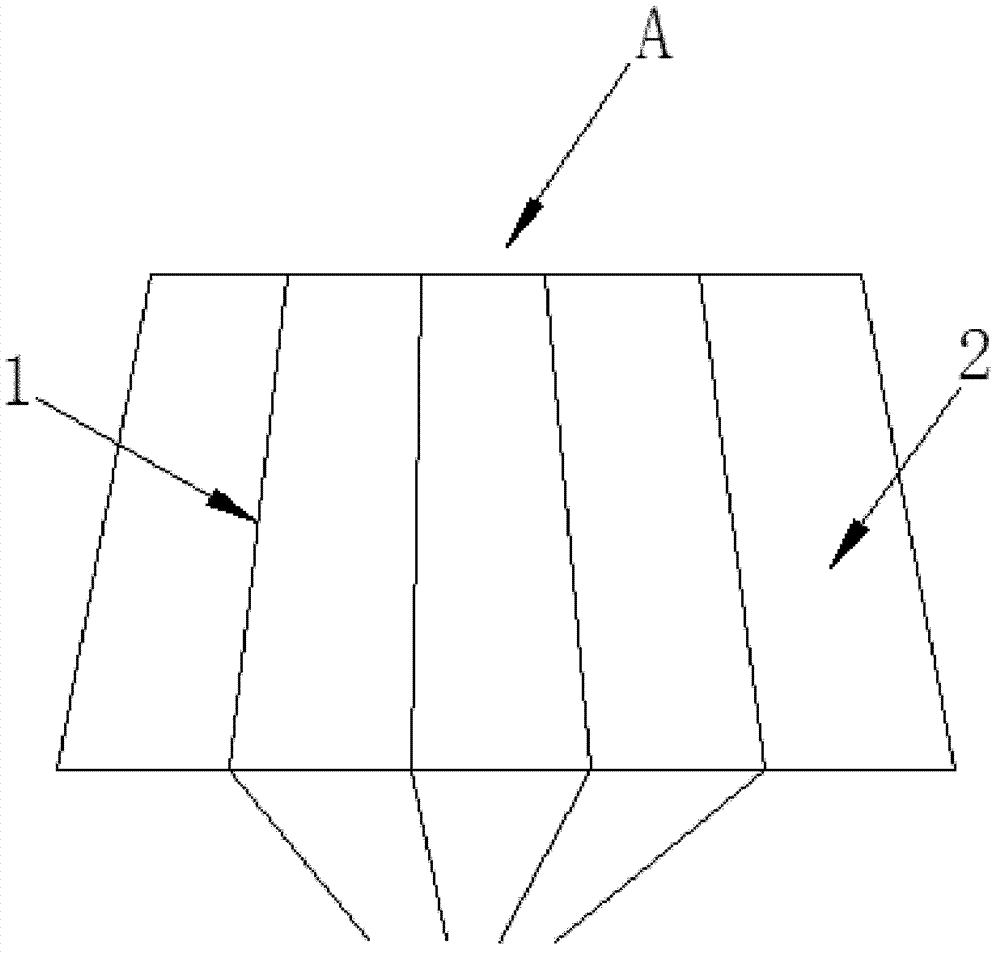

[0012] Embodiment: a temperature-sensing plate of a pressing machine is provided with several temperature-sensing wires, the temperature-sensing wires 1 are connected to the thermocouple thermometer, and a heat transfer plate 2 with heat transfer function is provided, and the temperature-sensing wires 1 is fixed on the heat transfer plate 2, and the temperature sensing line 1 and the heat transfer plate 2 constitute the temperature sensing plate A. When pressing, there is no need to stop the machine, only need to superimpose the temperature-sensing plate in parallel on the middle layer of the material layer to be pressed, which saves the process and time of slotting on the plate and connecting the temperature-sensing line, and can be used after pressing. Pull out the temperature sensing plate for the next reuse.

[0013] The heat transfer plate 2 is a metal plate.

[0014] The temperature sensing line 1 is buried and fixed in the heat transfer plate 2 .

[0015] Several temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com