Wind turbine blade with narrow shoulder and relatively thick airfoil profiles

A technology of wind turbine and relative thickness, which is applied to wind turbines, wind turbines, motors, etc., which are consistent with the wind direction, can solve the problem that the blades of the wind turbine model cannot be replaced, and achieve the effect of reducing storm load and low trailing edge curvature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0076] Examples of wind turbine blades according to the invention are given below.

[0077] A wind turbine blade is provided with the following parameters regarding length, shoulder width, minimum radius of curvature for the trailing edge and root cylinder diameter:

[0078] parameter size L 42.13m L w 8.5m W 2.975m r o 10.3m r i 11.3m D 1.893m

[0079] Table 1

[0080] Chord length c, relative thickness t / c, and pre-bending Δy The distribution of is listed in Table 2:

[0081]

[0082] Table 2

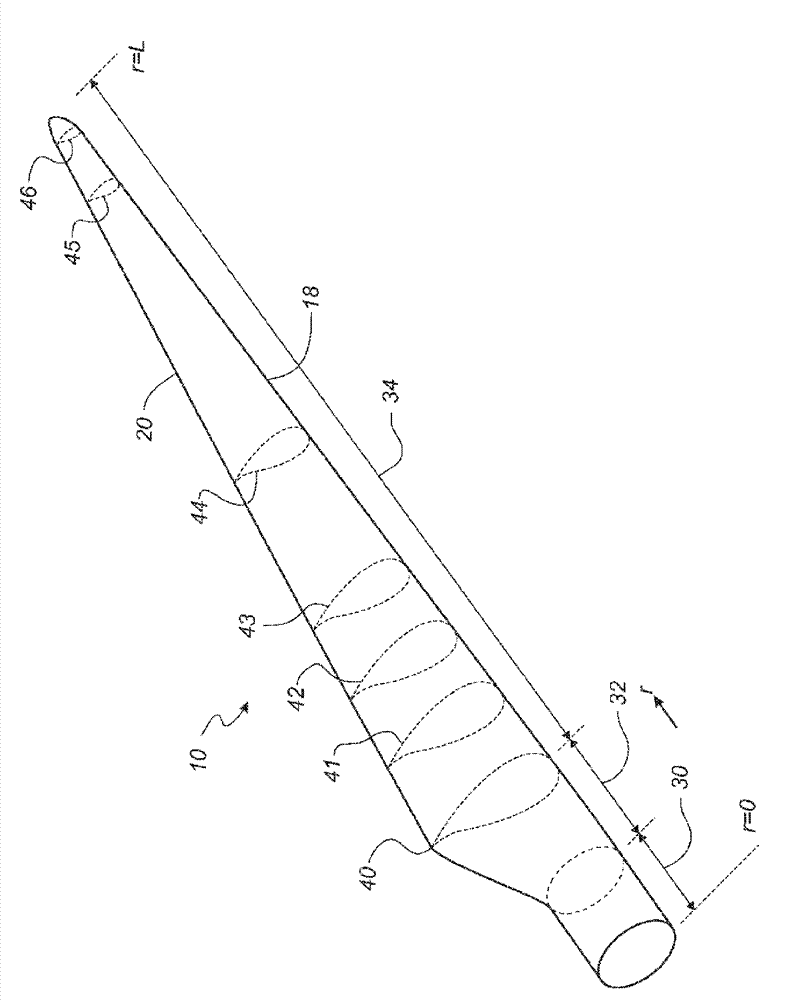

[0083] The wind turbine blade comprises six novel blade profiles 41-46 located at different longitudinal positions along the blade and such as figure 2 shown. Table 3 lists the relative thickness t / c of the profile and the position d of the maximum thickness t / c, position d of maximum pressure side camber p / c and approximate radial position r:

[0084] airfoil reference mark t / c d t / c d p / c r ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com