Mini-type metacarpal bone and finger bone external fixing support

A metacarpophalangeal and external fixation technology, applied in the field of external fixation devices, can solve problems such as affecting the function and the inability of early exercise of fingers, and achieves the effects of firm fixation, satisfactory recovery of appearance and function, and reduction of tendon adhesions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

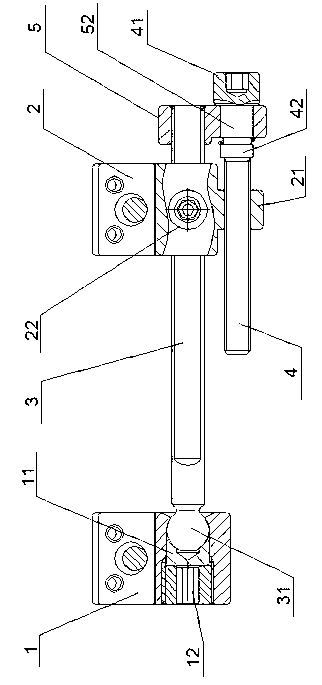

[0026] refer to figure 1 , in this embodiment, the microcarpal and phalangeal fracture external fixation bracket includes a first clamping block 1 and a second clamping block 2 , and the first clamping block 1 and the second clamping block 2 are connected by a connecting rod 3 .

[0027] The second clamping block 2 is provided with a through hole, the connecting rod 3 passes through the through hole, and one end is connected to the clamping block 1 .

[0028] The second clamping block 2 is provided with a threaded hole to communicate with the through hole and the outside, and the compression screw 22 is screwed in from the threaded hole to fix the connecting rod 3 .

[0029] When in use, the bone needle is fixed on the bone, and the outer end is clamped by the first clamping block 1 and the second clamping block 2, thereby realizing the connection of broken bones.

Embodiment 2

[0031] On the basis of embodiment 1, with reference to figure 1 The connecting rod 3 is connected with a fixed block 5 at the outer end of the second clamping block 2 , and the fixed block 5 is provided with a through adjusting screw hole 52 on the side of the connecting rod 3 .

[0032] The second clamping block 2 is also provided with a protruding part 21 on the side of the through hole, and the protruding part 21 is provided with a through adjusting screw screw hole, the adjusting screw hole 52 of the fixed block 5 and the adjusting screw screw of the second clamping block 2 The holes are on the same straight line.

[0033] The adjusting screw 4 passes through the adjusting screw hole 52 of the fixing block 5 and the adjusting screw hole of the second clamping block 2 in sequence.

[0034] Rotate the adjusting screw 4, the second clamping block 2 can move back and forth, thereby driving the bone nail clamped by the second clamping block 2 to move forward and backward, ther...

Embodiment 3

[0037] On the basis of embodiment 1 or 2, with reference to figure 1 , the first clamping block 1 is provided with a spherical cavity, one end of the connecting rod 3 inserted into the first clamping block 1 is a spherical end 31, and the spherical end 31 is placed in the spherical cavity to form a universal joint with the spherical cavity .

[0038] The connection between the connecting rod 3 and the first clamping block 1 is designed as a universal joint, which has good adjustability and can effectively correct the fracture rotation or angular deformity. If the fracture is found to be angled or rotated after surgery, it can be obtained by adjusting the fracture. Good alignment of fractures.

[0039] In this case, there is an arcuate block 11 at the rear end of the spherical cavity, and the rear end of the arcuate block 11 is a clamping screw 12 for better control of the universal joint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com