Numerical-control cutting machine combined with water jet scalpel and dicing saw

A technology of water cutting machine and cutting saw, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of slow water cutting speed, not as fast as speed, not suitable for cutting curves, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

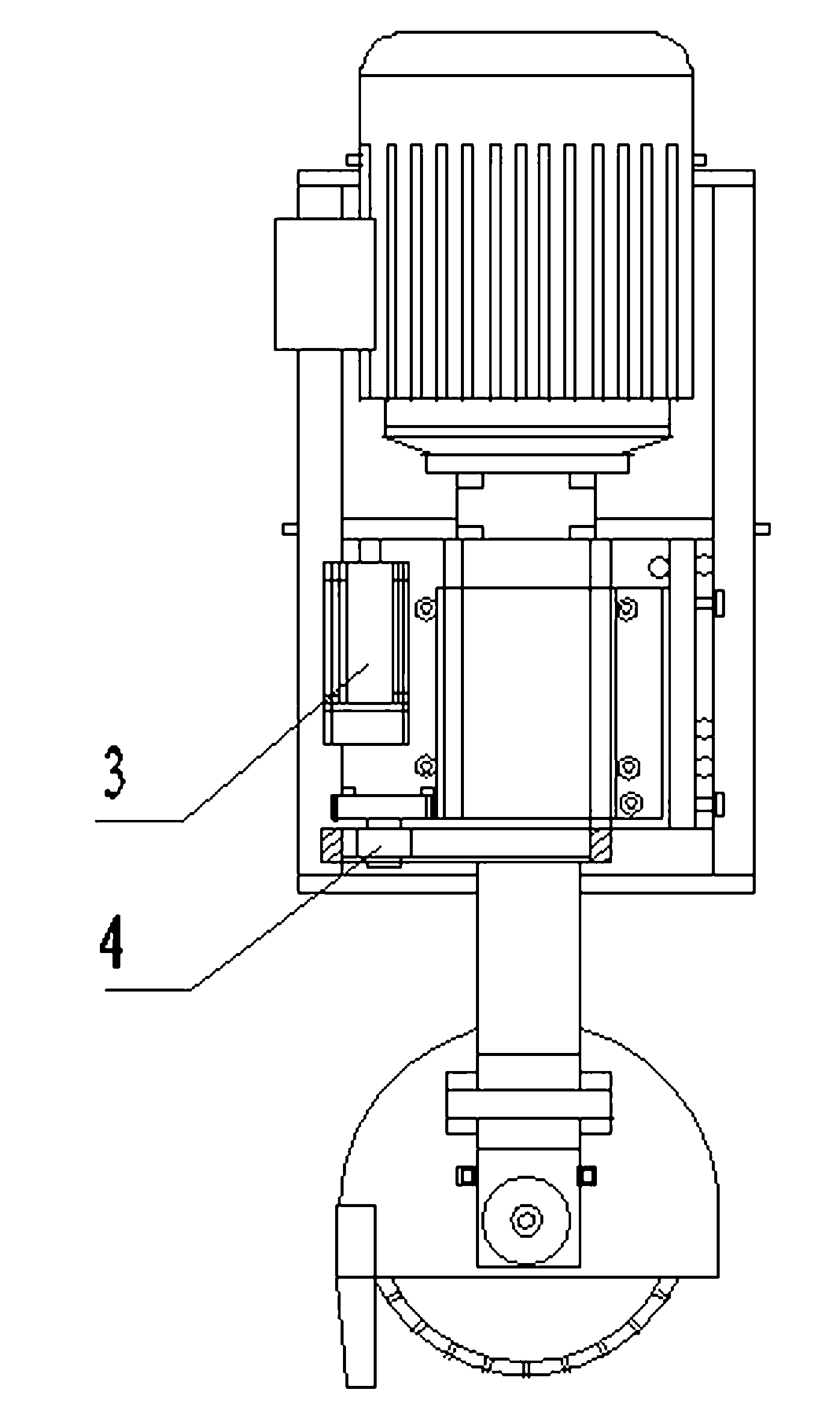

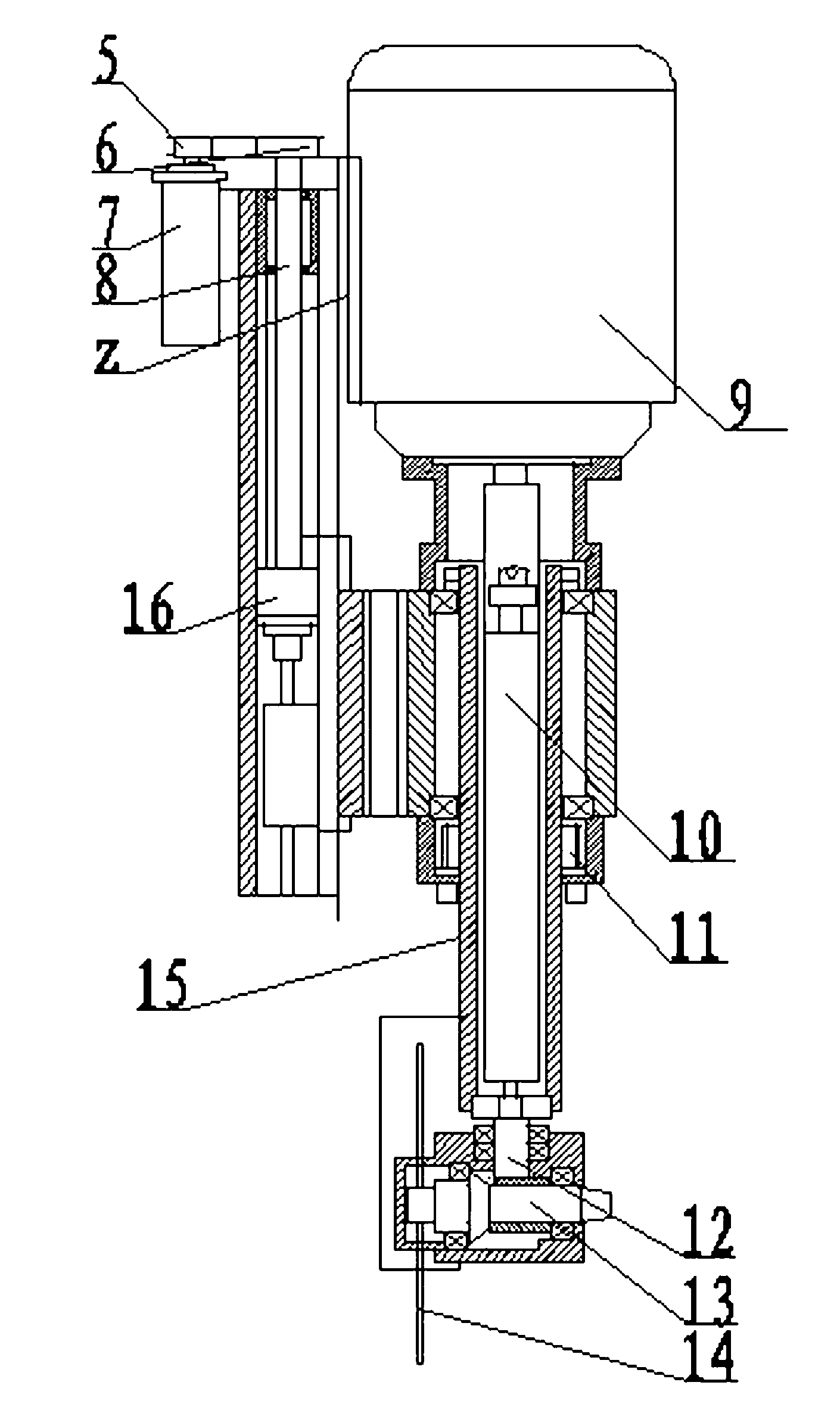

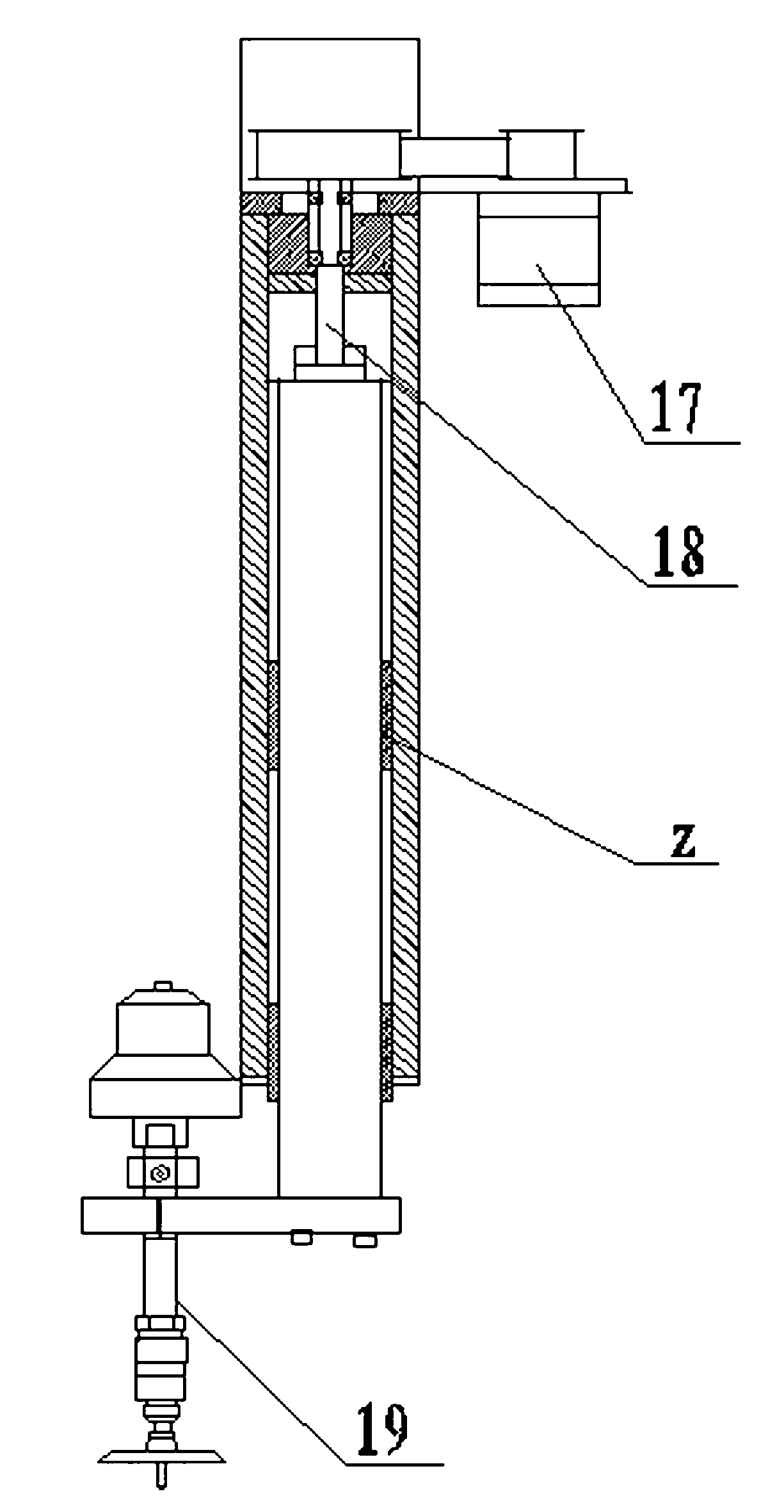

[0011] CNC cutting machine combined with water jet and cutting saw, including X axis of CNC water cutting machine, Y axis of CNC water cutting machine, water cutting device 2 set on the X axis of CNC water cutting machine, which can be lifted along the Z axis of water jet, can move along the cutting saw Z-axis lifting saw device 1. The cutting saw device is composed of a cutting saw Z-axis lifting transmission mechanism, a cutting saw driving mechanism and a cutting saw rotation transmission mechanism. The cutting saw Z-axis lifting transmission mechanism includes a cutting saw Z-axis lifting motor 7 , a cutting saw lifting driving pulley 5 , a cutting saw lifting driven pulley 6 , and a cutting saw lifting screw rod 8 . The cutting saw lifting driving pulley 5 is installed on the output shaft of the cutting saw Z-axis lifting motor 7, the cutting saw lifting driven pulley 6 is mounted on the cutting saw lifting screw rod 8, the cutting saw lifting driving pulley 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com