Front-end train assembly with anti-creeping energy-absorbing device

An energy-absorbing device and anti-climbing technology, applied in transportation and packaging, railway car body parts, railway vehicle wheel guards/buffers, etc., can solve the problems of reduced train strength, unfavorable end beam strength, mechanical properties changes, etc. , to achieve the effect of reducing and eliminating the impact force, highlighting the substantive characteristics, and reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

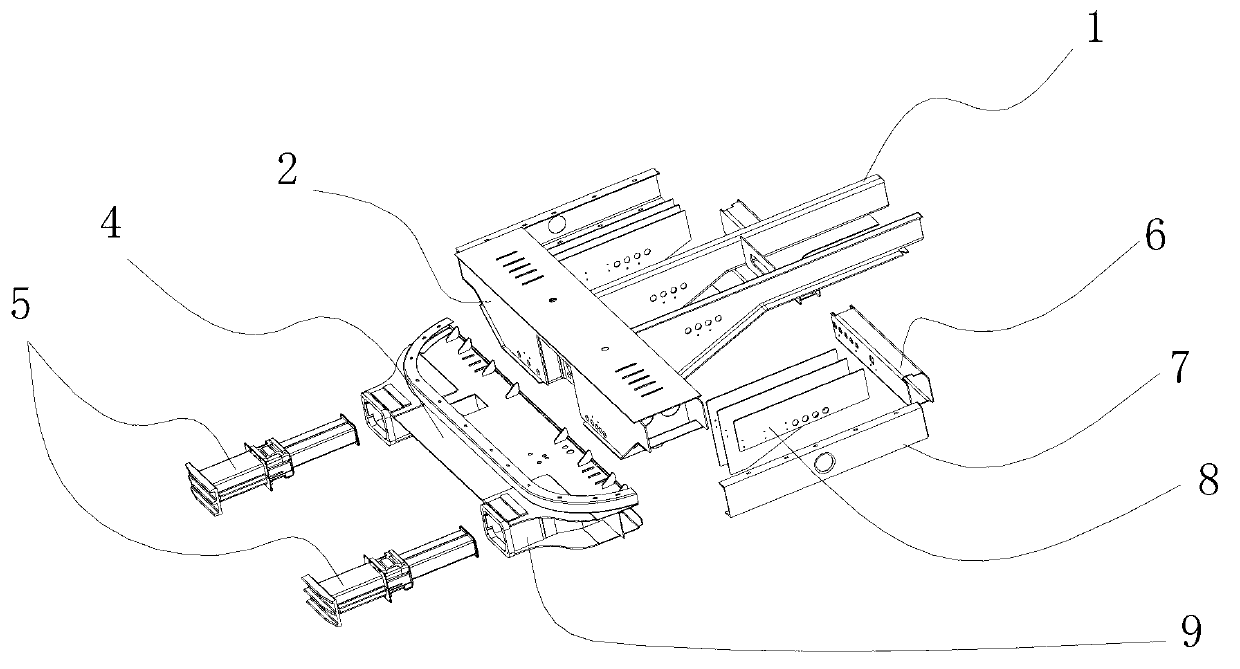

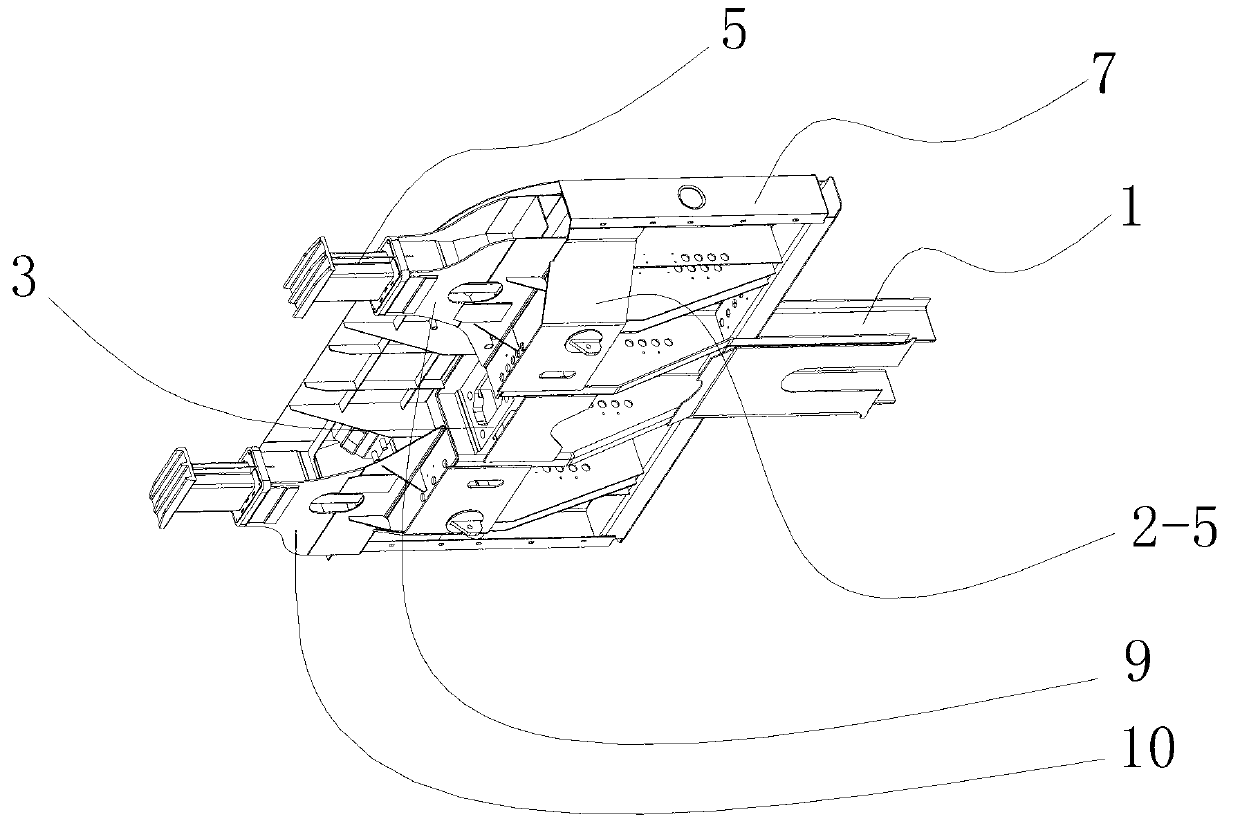

[0024] according to figure 1 As shown, the front end of the train with the anti-climbing energy-absorbing device in the present invention comprises a coupler box 2 connected to the front end of the traction beam 1 of the car body, a coupler mounting seat 3, an anti-climbing energy-absorbing device mounting seat 4 and an anti-climbing energy-absorbing device 5.

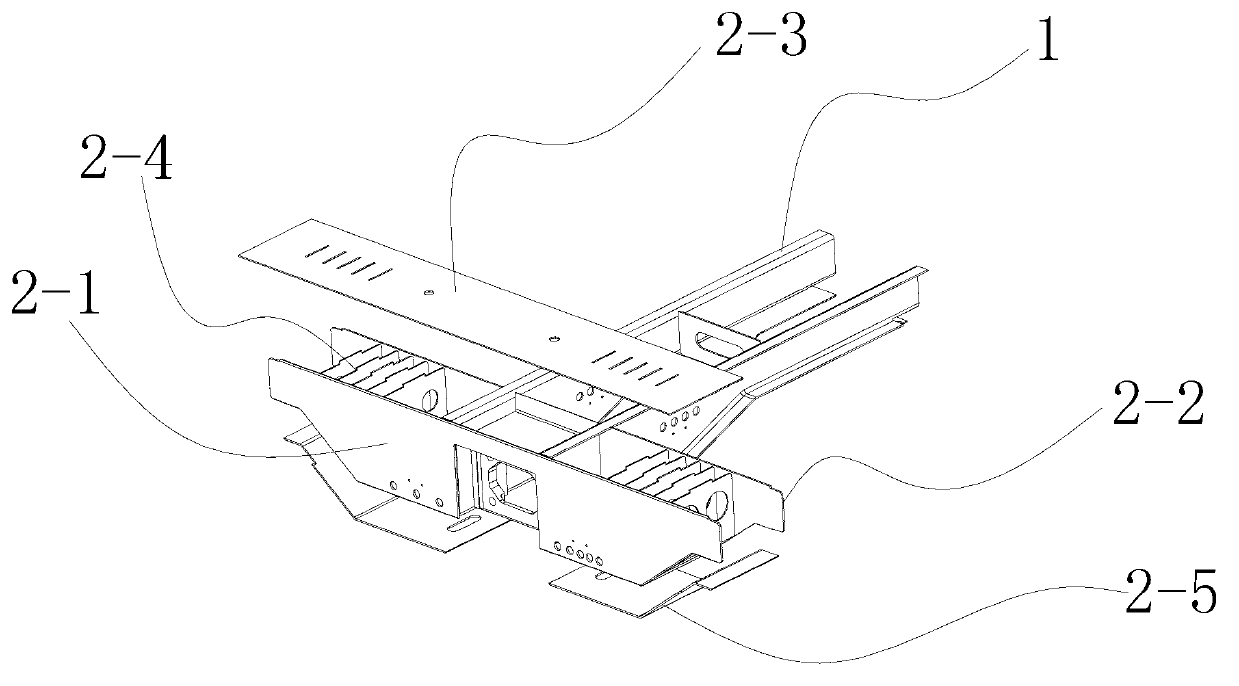

[0025] Among them, the coupler box 2 is mainly a box-shaped structure welded by the web, the upper cover plate 2-3, the partition plate 2-4 and the bottom plate 2-5. Two webs 2-1, 2-2. The coupler box 2 has a channel for the longitudinal passage of the coupler and the coupler mounting seat 3. The first and second webs 2-1, 2-2 and the coupler mounting seat 3 are respectively provided with rectangular gaps for the coupler to pass through. 1. The top of the second web 2-1, 2-2 is connected with an upper cover 2-3, the first and second web 2-1, 2-2 are connected with a partition 2-4, the first, The bottoms of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com