Electromagnetic reel

A reel and electromagnetic technology, applied in the textile field, can solve the problems of cumbersome design, production and installation, production interruption, labor consumption and other problems, and achieve the effect of convenient control and viewing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described:

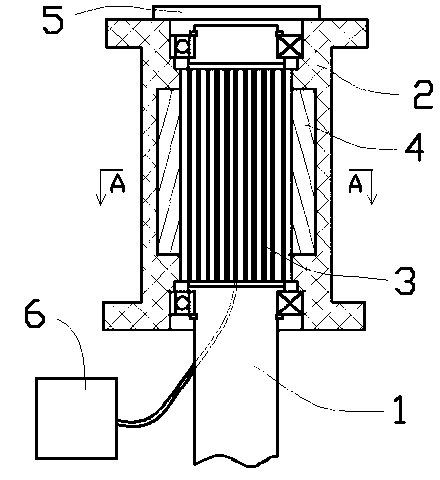

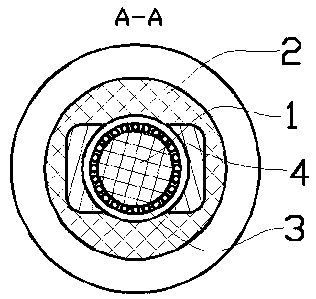

[0015] Such as figure 1 and figure 2 As shown in the embodiment, the electromagnetic reel includes a fixed shaft 1 and a rotating wheel 2; the fixed shaft 1 and the rotating wheel 2 are coaxially rotatable, and the fixed shaft 1 and the rotating wheel Use bearing to connect between wheel 2. The fixed shaft 1 is equipped with a metal coil 3 connected to the circuit, and the inner surface of the rotating wheel 2 is equipped with a pair of magnets 4 ; the position of the magnet 2 is symmetrical with respect to the axis of the fixed shaft 1 .

[0016] The electromagnetic winding wheel is used on the spinning machine, and adopts an electromagnetic structure. By passing an alternating current to the metal coil 3, an alternating magnetic field is generated, and the rotating wheel 2 equipped with a pair of magnets 4 is driven to rotate to complete the winding. action. Since the fixed shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com