Device and method of bus control of molecular pump

A bus control and molecular pump technology is applied in the detection and control of molecular pumps, the detection and control device of photovoltaic conductive glass production lines, and the field of magnetic control of conductive glass for solar thin film batteries, which can solve the inconvenience and control of molecular pump dynamic parameters. The problems of high module consumption and high equipment failure rate can achieve the effect of increasing stability, reducing failure rate and improving the ability of normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] For further elaborating the technical means and effect that the present invention takes to achieve the predetermined invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the molecular pump on the conductive glass magnetron sputtering equipment of a kind of solar thin film battery that proposes according to the present invention The bus control device and method are described in detail as follows.

[0025] Different embodiments of the present invention will be described in detail below to implement different technical features of the present invention. It should be understood that the units and configurations of the specific embodiments described below are used to simplify the present invention, which are only examples and not limiting scope of the invention.

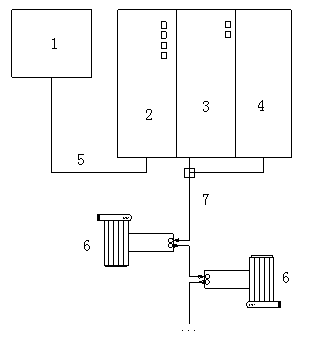

[0026] figure 1 Shown is the bus control device of the molecular pump on the solar thin film battery conductive glass magnetron sputtering equipment, which includes: mai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap