Main bearing sealing system for wind generating set

A technology for wind turbines and sealing systems, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of burnt out bearings, unavailability of bearings, waste of lubricating grease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

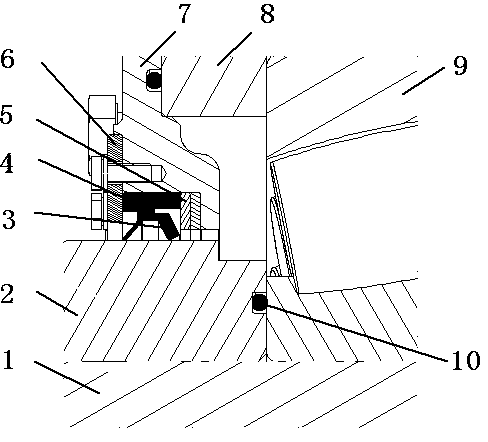

[0012] figure 1 The marks shown are as follows: main shaft 1, bearing front positioning ring 2, skeleton oil seal 3, V-shaped dust ring 4, sealing spacer 5, front sealing end cover 6, bearing front end cover 7, bearing housing 8, main bearing 9, O-ring 10.

[0013] figure 1 A new type of sealing device for the main bearing of a wind power generating set is shown, including bearing front and rear positioning rings, front and rear sealing covers, sealing spacers, skeleton oil seals, V-shaped dustproof rings, O-rings, front and rear bearing end covers, etc.

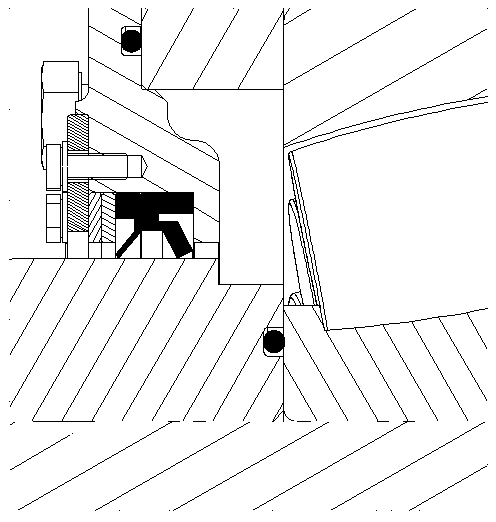

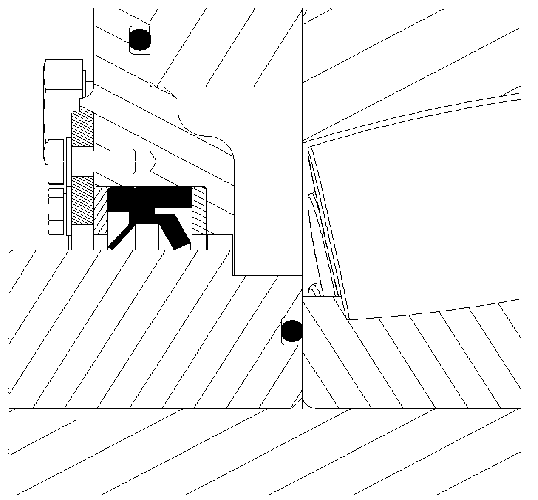

[0014] figure 1 It is the structural relationship of each component of the sealing system when it is put into operation for the first time. When it is detected that the contact parts between the V-shaped dustproof ring, the skeleton oil seal and the front and rear positioning rings of the bearing, and the dents caused by scratches exceed the allowable value, remove a piece of spacer on the outside and adjust it to figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com