A rubber shock absorber with high dynamic and static stiffness ratio for high-speed trains

A technology for rubber shock absorbers and high-speed trains, applied in springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve problems such as short service life of equipment, low dynamic stiffness, and system instability , to achieve good vibration damping function, small lateral stiffness, good vibration isolation and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

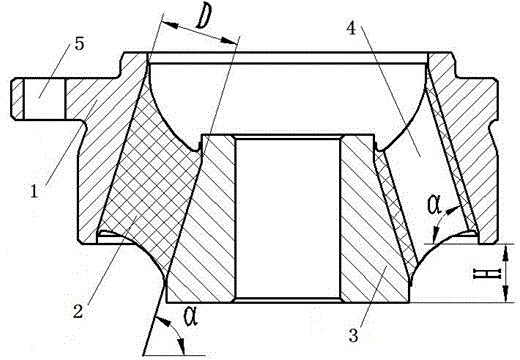

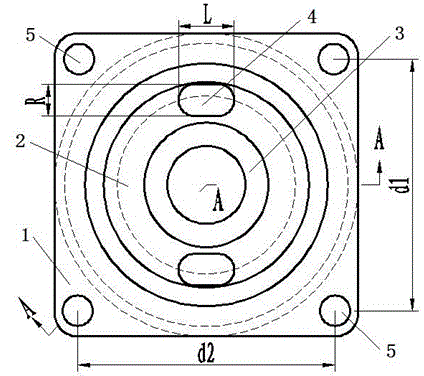

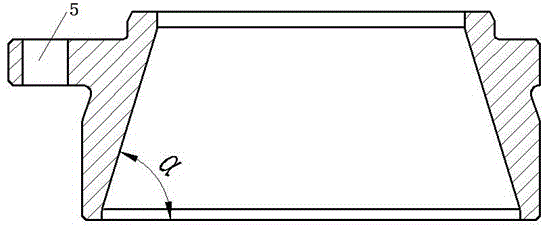

[0024] Embodiment 2: The difference from Embodiment 1 is that two through holes 4 are provided along the inclination direction of the vulcanized rubber layer 2 at the symmetrical position of the vulcanized rubber layer 2 at a 90° direction from the horizontal position, that is, the inclination angle of the through hole 4 The angle is the same as the inclination angle of the cross-section of the inner wall of the metal jacket 1. The function of opening the through hole 4 is to adjust and reduce the transverse stiffness of the rubber shock absorber, so that the transverse stiffness of the rubber shock absorber is small and the longitudinal stiffness is large. The shock absorber has different stiffness characteristics in the longitudinal direction and the transverse direction to meet the vehicle dynamics requirements; the cross section of the through hole 4 is a waist hole; the lateral stiffness of the rubber shock absorber can be adjusted by adjusting the size of the through hole ...

Embodiment 3

[0025] Embodiment three: the difference from embodiment two is that the numerical relationship between the length and width of the cross-section of the through hole 4 is L=2R+8mm (L represents the length of the cross-section of the through hole, and R represents the length of the cross-section of the through hole. width of the cross-section of the hole), in this embodiment, the length of the cross-section of the through-hole 4 is 16mm, and the width of the cross-section of the through-hole 4 is 4mm. Of course, in other embodiments, the cross-section of the through-hole 4 The length of the cross-section and the width of the cross-section of the through hole 4 can also be other values that satisfy the aforementioned conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com