Elastic support structure of planet wheel

An elastic support, planetary gear technology, applied in belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems affecting the meshing accuracy of the planetary gears, the limit of the number of planetary gears used, and the large size of the gearbox. Achieve the effect of reducing machining accuracy, good load sharing, and reducing overall size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

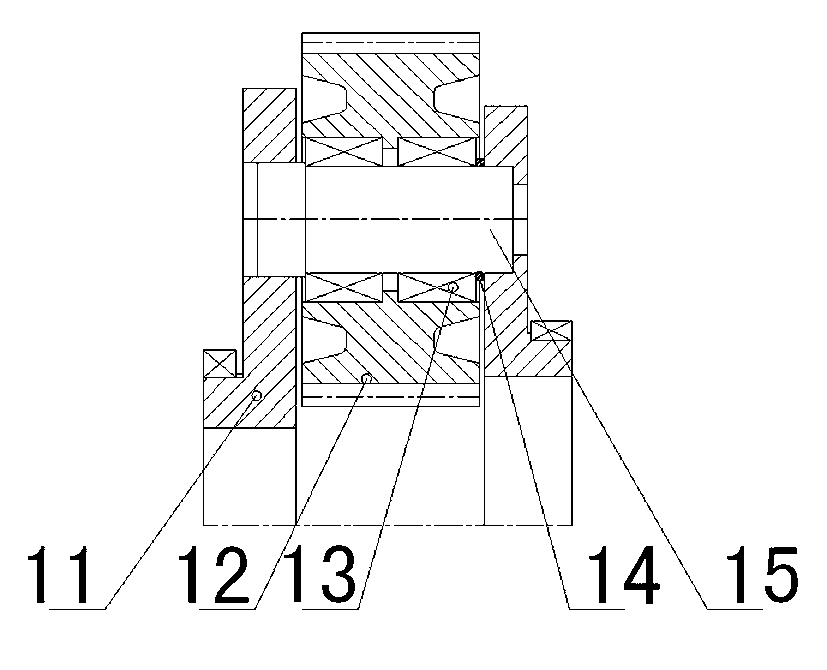

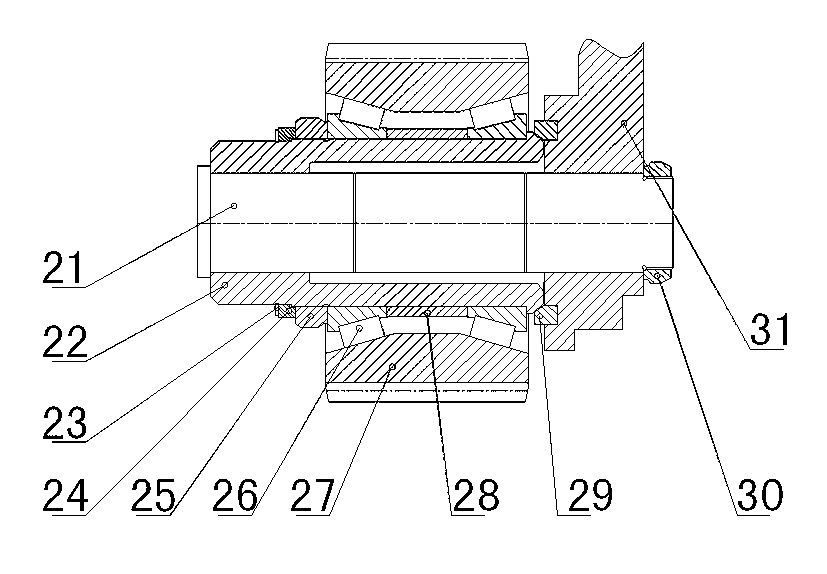

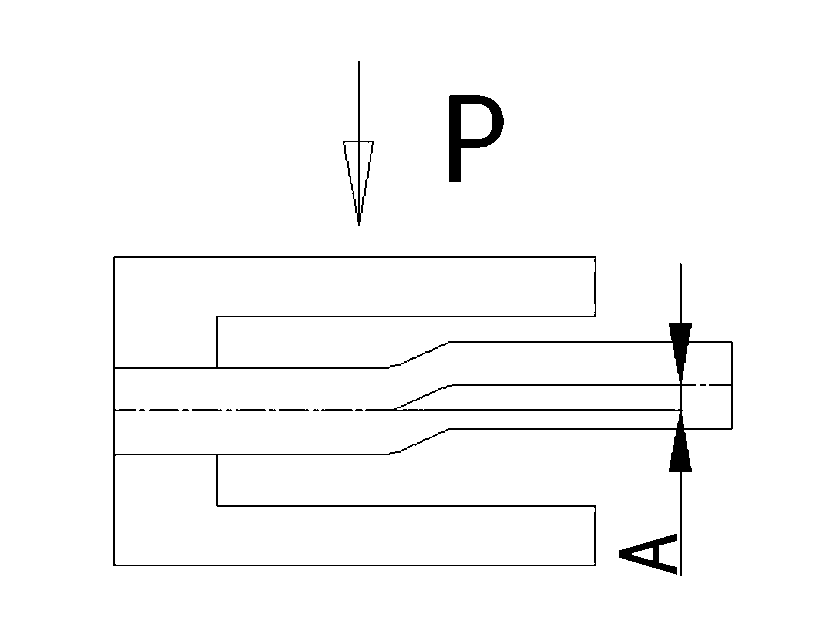

[0021] Example: such as figure 2 : the planetary wheel 27 is supported on the planetary shaft 22 through two tapered roller bearings 26 without outer rings, the bearing ends are locked with a round nut 25, and the round nut 25 is equipped with an adjusting spacer ring 24 and a spring retaining ring 23 , together with the round nut 25, the bearing 26 has a double protection effect, which greatly improves the operational reliability of the product. The planet shaft 22 is in interference connection with the planet pin 21 , and the planet pin 21 is also in interference connection with the bracket 31 . A round nut 30 is installed at the end of the planetary pin 21 for axial positioning. Such as image 3 As shown, when the planetary wheel 27 is stressed, the planetary pin 21 is elastically deformed, and the offset is A. The limiting cone ring 29 has an overload protection effect on the planetary pin 21 when the planetary wheel 27 is overloaded.

[0022] Since the planetary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com