Double-plate type ball valve

A plate type, ball valve technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as non-compact operation, the valve stem cannot be controlled and driven step by step, and the valve structure is complex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

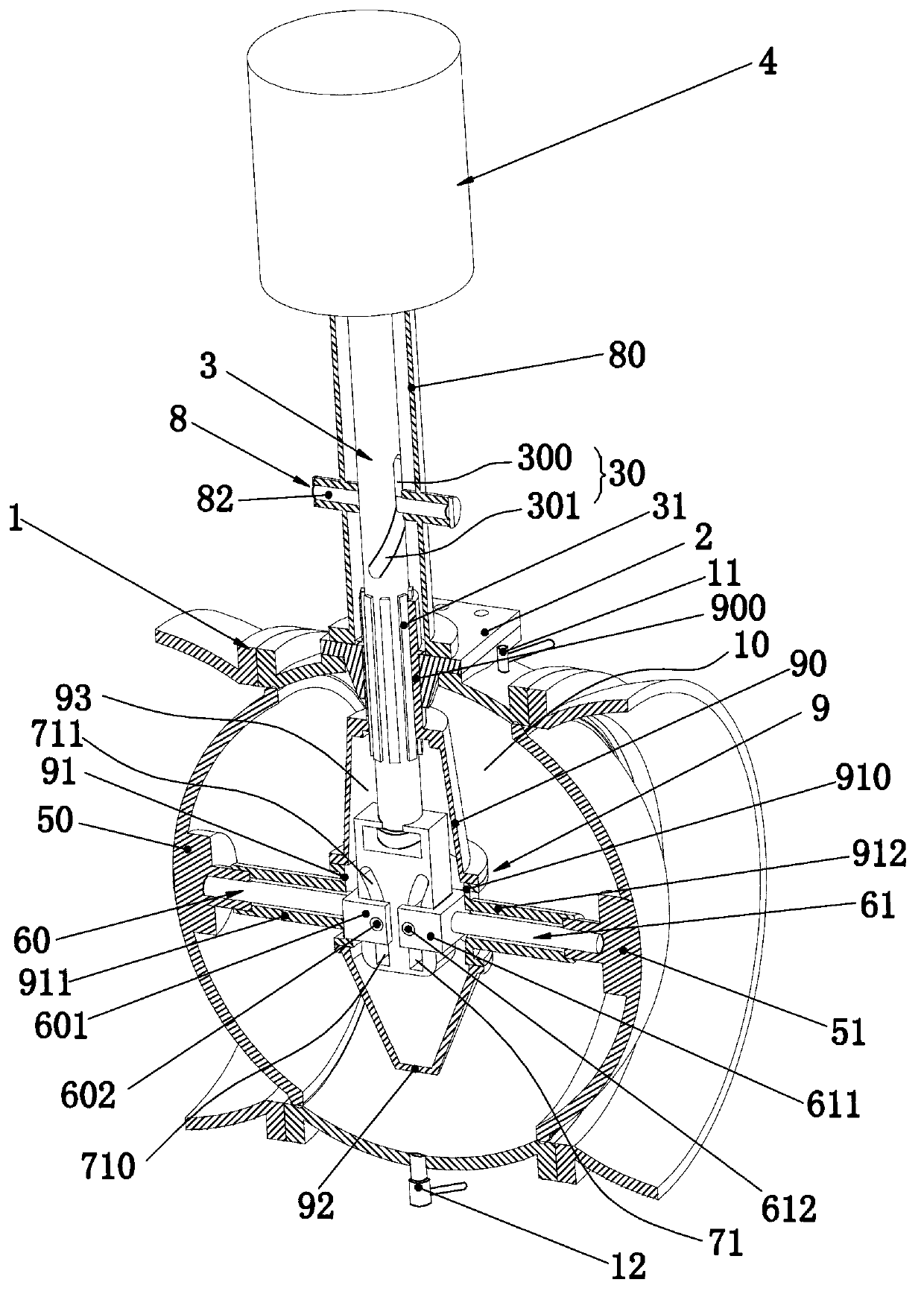

[0015] See attached figure 1 , a double-plate ball valve disclosed by the present invention includes a valve body 1, a valve cover 2, a valve disc, a valve stem 3 and a driving device 4. The valve body 1 is provided with a valve chamber 10, which is located at the inlet and outlet of the fluid. The valve seat is set, the valve body 1 is provided with inlet and outlet valves 11, 12 communicating with the valve cavity 10, the valve disc is provided with left and right spherical bodies 50, 51 which are sealingly matched with the valve seat, and the left spherical body 50 is fixedly connected with a left The telescopic rod 60, the right spherical body 51 is fixedly connected with the right telescopic rod 61, the valve rod 3 is movably inserted on the valve cover 2, one end of the valve rod 3 passes through the valve cover 2 and extends into the valve chamber 10, and the end is installed with a valve Rod 3 axially moves and slides up and down the inclined iron 7, and the inclined i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com