Bulk molding compound (BMC) electric heating floor tile

A technology for electric heating floor tiles and floor tiles, which is applied in electric heating systems, heating methods, household heating, etc., can solve the problems of high structural floor and unfavorable bathroom drainage, etc., and achieves the effects of strong decoration, safe and reliable use, and moderate heating temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

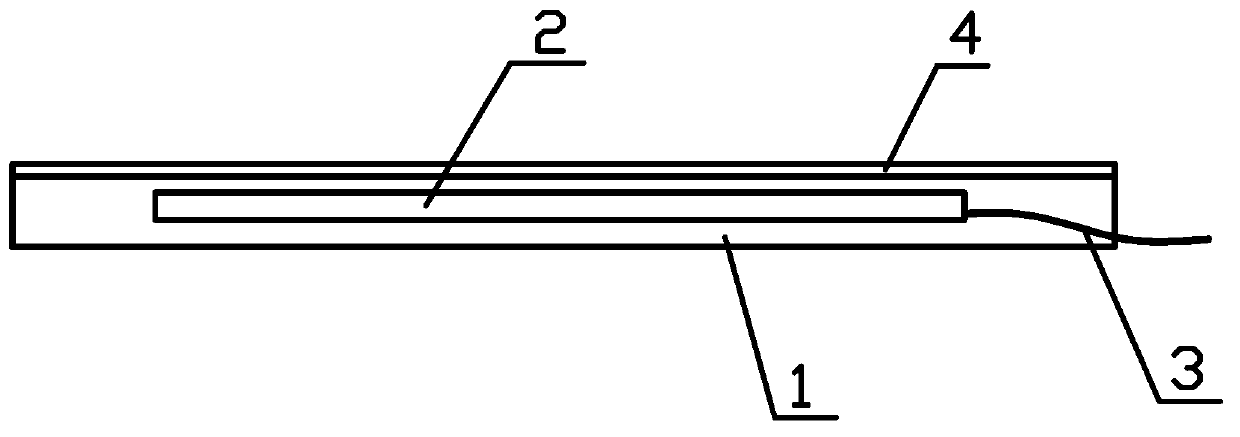

[0014] Such as figure 1 As shown, the BMC electric heating floor tile is composed of a floor tile main body 1, an electric heating device and a wire 3, the electric heating device is a semiconductor heating sheet 2, and the semiconductor heating sheet 2 is arranged in the middle of the floor tile main body 1, and one end of the wire 3 is connected to the The semiconductor heating sheet 2 is connected. The floor tile main body 1 of this embodiment is made of BMC material, and the BMC material encapsulates the semiconductor heating sheet 2 and the wire 3 in the inside of the floor tile main body 1 by molding, and forms an integral structure. stick out.

[0015] In this embodiment, the heating temperature of the semiconductor heating sheet 2 is 45°C to 60°C. The surface of the floor tile main body 1 is also provided with a layer of decorative material 4, and the wire 3 is a silicone insulated wire. The present invention adopts an integral molding structure, and the semiconduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com