Magnetic sensor and manufacturing process thereof

A magnetic sensor and manufacturing process technology, applied in buoy liquid level indicators and other directions, can solve problems such as poor pressure resistance and stability under water immersion, complex structure, etc., and achieve the effects of avoiding contact with water, increasing sensitivity, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

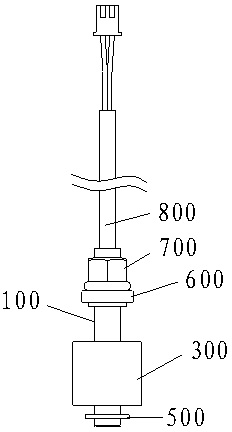

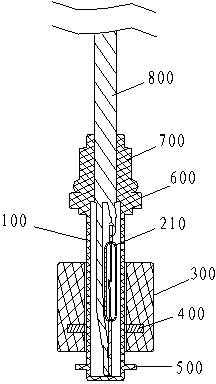

[0036] Such as figure 2 As shown, in this embodiment, the magnetic sensor is set as a reed switch 210 .

[0037] The magnetic sensor includes a housing 100, a reed switch 210, a float 300, a permanent magnet 400, a limit ring 500, a limit block 600, and a rotating sliding sleeve 700; 210 and the electric wire 800 are welded and placed vertically into the housing 100; in this embodiment, the float 300 is arranged in a ring shape, and the permanent magnet 400 is arranged on the inner surface of the float 300, specifically, the permanent magnet 400 is arranged in a ring shape, The permanent magnet 400 is concentric with the float 300; the shell 100 passes through the float 300, in order to prevent the float 300 from breaking away from the shell 100 in actual work, the upper end of the shell 100 is provided with a limit block 600 to limit the upward movement distance of the float 300, inside the shell 100 The dry reed switch 210 cooperates with the permanent magnet 400 on the in...

Embodiment 2

[0045] In this embodiment, except that the welding position of the reed switch 210 and the electric wire 800 is different from that described in Embodiment 1, other structures are the same as those described in Embodiment 1.

[0046] In this embodiment, the connection mode between the reed switch 210 and the electric wire 800 is as follows Figure 7b as shown, Figure 7b Among them, h4 represents the length of the lead wire at the upper end of the reed switch 210, h5 represents the distance between the bottom end of the glass tube of the reed switch 210 and the welding point between the bottom end of the reed switch 210 and the wire 800, and h6 represents the bottom end of the reed switch 210 and the wire 800 The distance between the welding place and the lowest end of the lead wire at the lower end of the reed switch 210. In the manufacturing process of the magnetic sensor described in the present invention, it is necessary to use resin to fill the housing 100 to protect and...

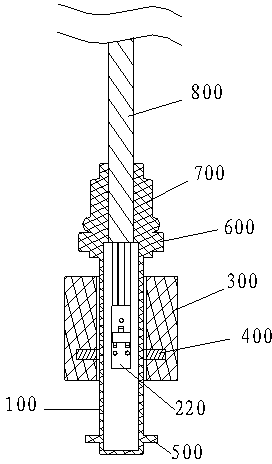

Embodiment 3

[0048] Such as image 3 As shown, the magnetic sensitive element in this embodiment is MR (Magneto Resistance) magnetoresistor 220, and other structures are the same as those described in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com