Preparation method of color ink powder for printers

A technology for color toners and printers, applied in the field of pigments, can solve the problems of fast fading, poor color, unfavorable long-term storage and large-scale printing, etc., and achieves the effect of simple process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

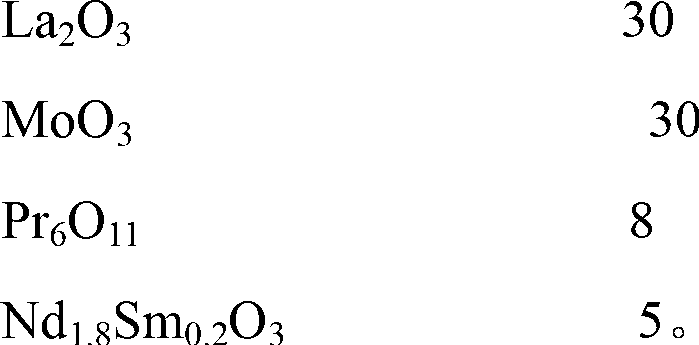

Embodiment 1

[0027] 1. Mix the raw materials for removing silicon dioxide in the kneading device and transfer them to the extruding device for extrusion at 140°C;

[0028] Described toner, by mass percentage, is made up of following components:

[0029]

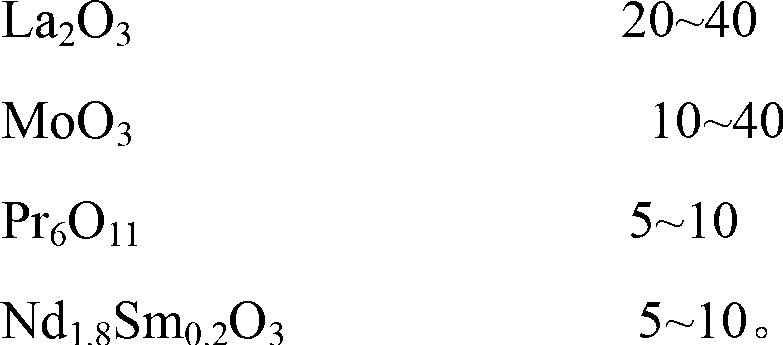

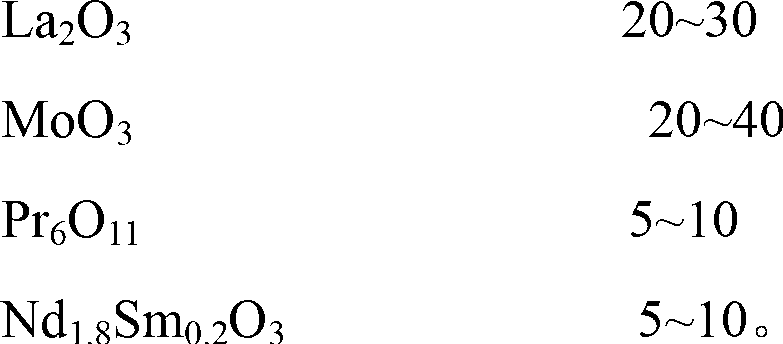

[0030] Described yellow pigment, by mass parts, is made up of following components:

[0031]

[0032] II. Coarsely pulverizing the fragments obtained in step I to an average particle size of 20 μm, and then further pulverizing to an average particle size of 2 μm;

[0033] III. Mix the granules obtained in step II with silicon dioxide to make the fluidity 20%, and then crush them through a 200-mesh sieve.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap