Motion positioning control system of vacuum equipment and control method

A technology of positioning control and vacuum equipment, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of heavy system wiring workload, complex software programming structure, poor scalability, etc., and achieve easy modification and simplified design , easy to maintain and expand the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] The solution of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

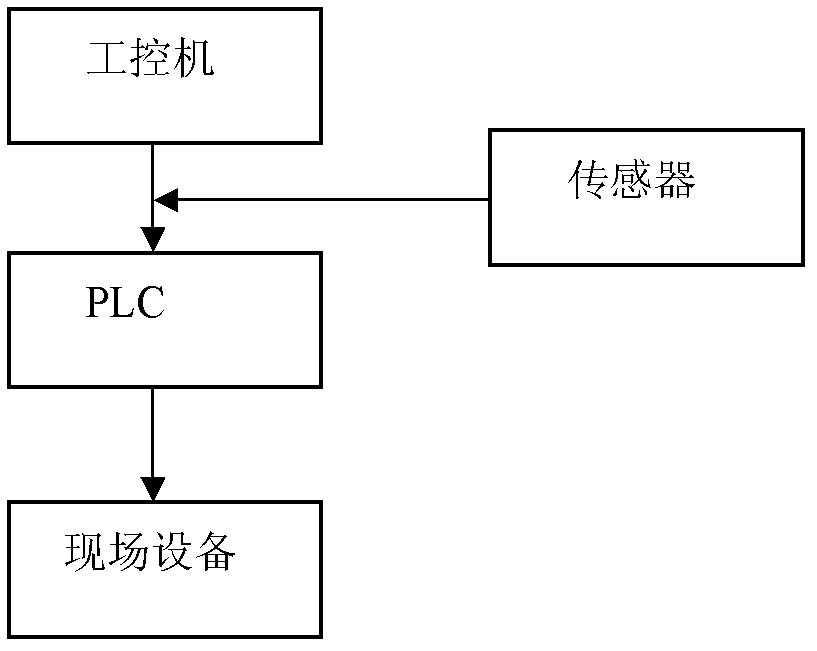

[0042] Such as figure 1 Shown is a block diagram of the system of the present invention. It is the system block diagram of the present invention. The invention is a vacuum equipment movement positioning control system, which is characterized by including PLC, industrial computer, field equipment and sensors; among them, PLC is the main control component, and its input terminal receives the field sensor signal, communicates with the industrial computer, and outputs Terminate field equipment; the industrial computer is the upper computer of the PLC, and the PLC control program is programmed, and the field equipment is controlled through the PLC. The field equipment includes a stepper motor driver and / or an AC servo motor driver and a motor. The motor is connected to the field sensor input terminal.

[0043] In this embodiment, the PLC uses the C...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap