Thermistor element

A thermistor element and resistance element technology, applied in the direction of resistors with negative temperature coefficient, resistors with positive temperature coefficient, etc., can solve the problem of poor heat transfer, unable to increase the maintenance current, low sensitivity to ambient temperature, etc. Problems, achieve the effect of improving the appearance, increasing the maintenance current, and increasing the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the above-mentioned and other technical contents, features, and advantages of the present invention more obvious and easy to understand, the following specific examples are given, and in conjunction with the accompanying drawings, detailed descriptions are as follows:

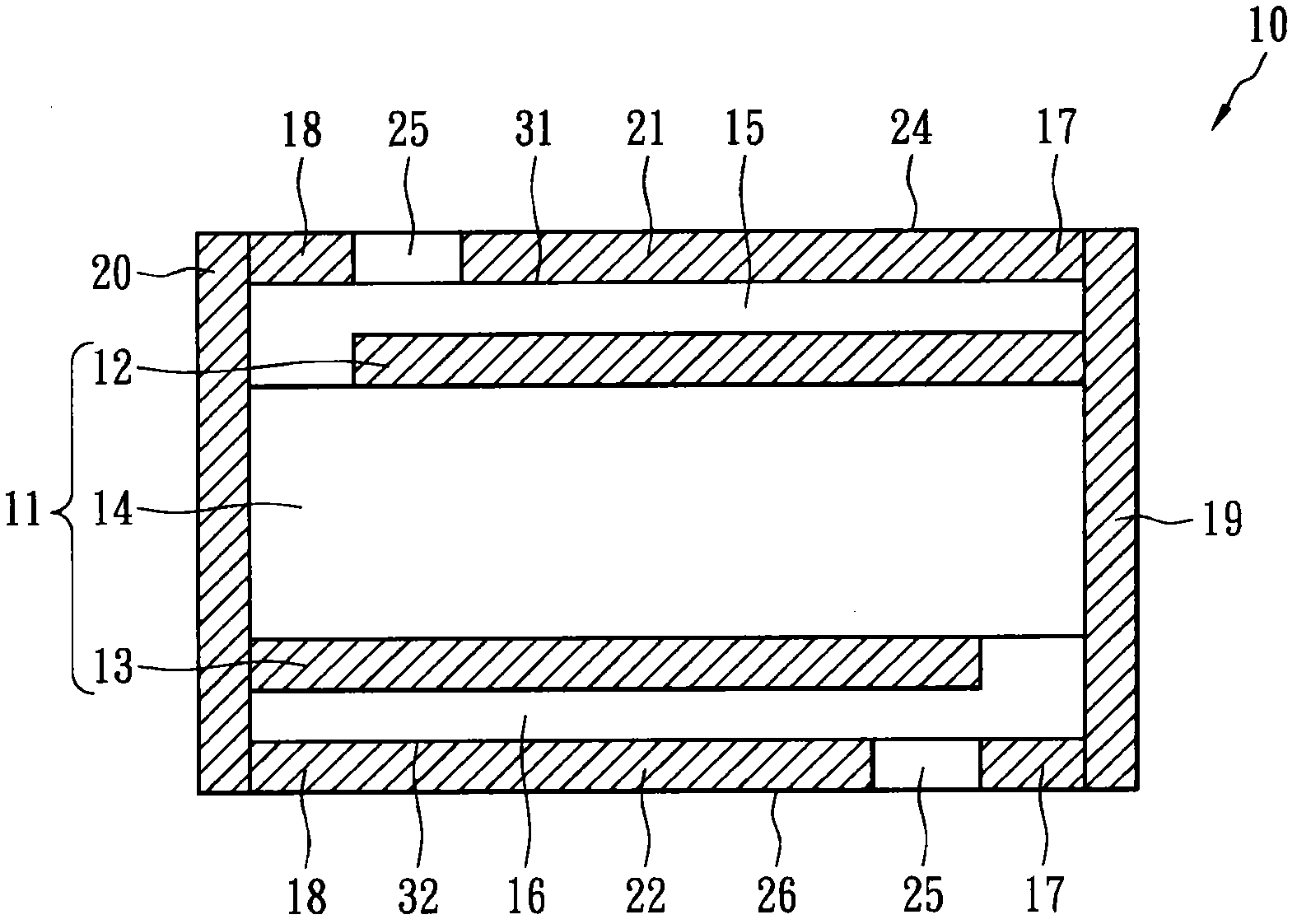

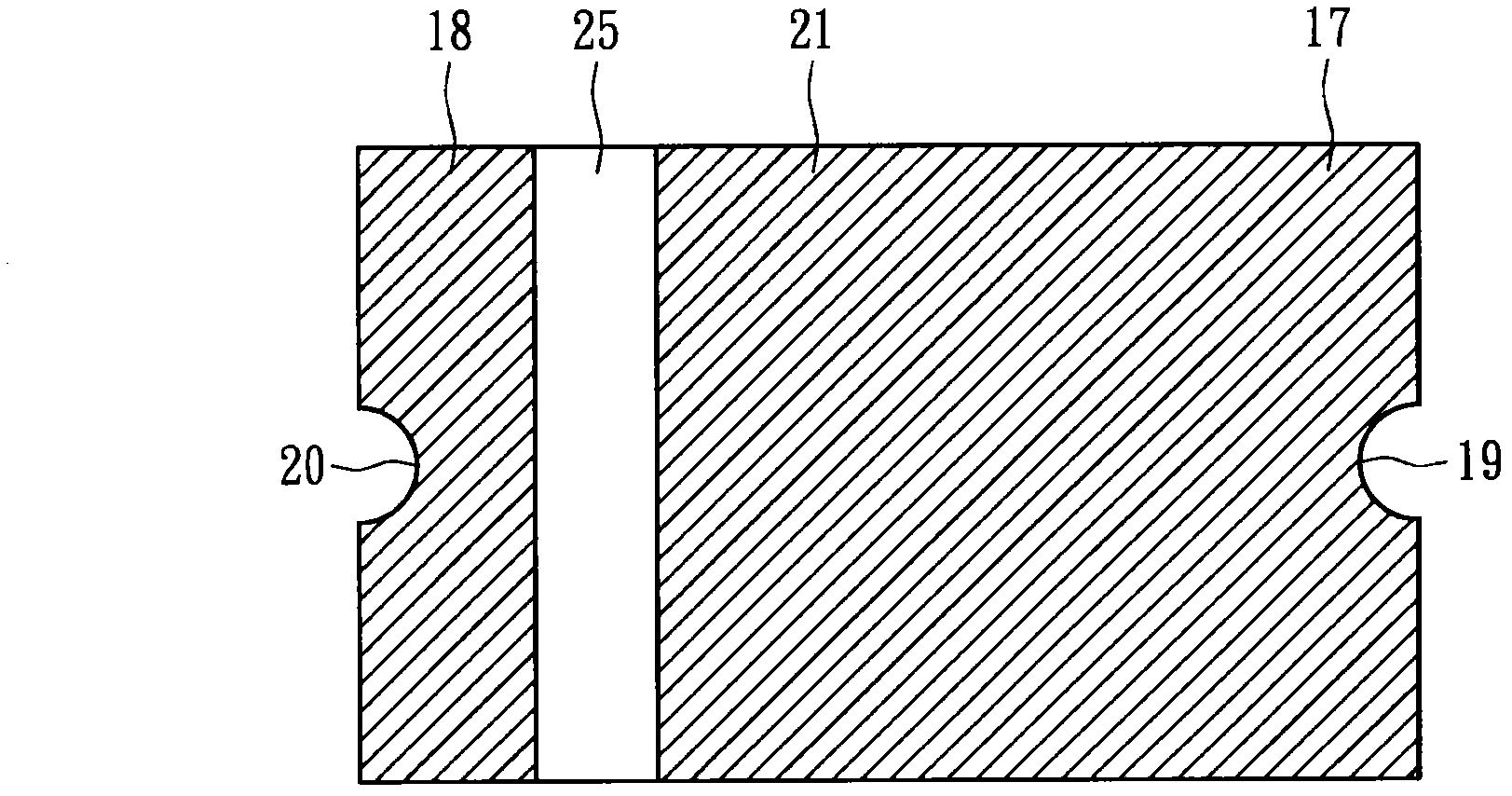

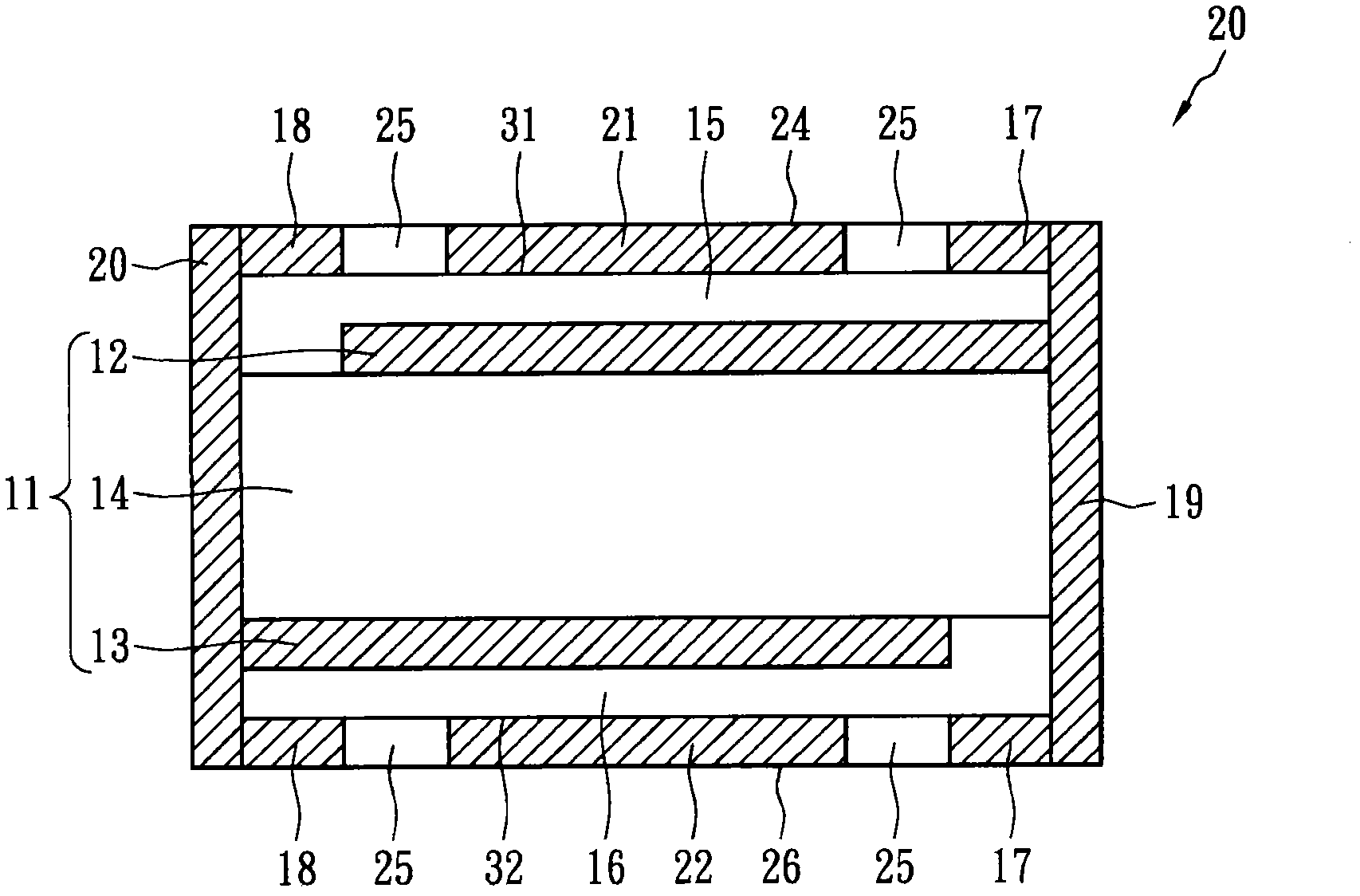

[0048] Figure 1A A schematic diagram of the thermistor according to the first embodiment of the present invention is shown. Figure 1B A top view of the thermistor element shown in FIG. 1 is shown. The thermistor 10 includes a sheet-type resistive element 11 , a first insulating layer 15 , a second insulating layer 16 , a first electrode 17 and a second electrode 18 . The sheet-type resistive element 11 includes a first conductive member 12, a second conductive member 13 and a polymer material layer 14, wherein the polymer material layer 14 is stacked between the first conductive member 12 and the second conductive member 13, which contains Conductive particles with positive or negativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com