Dry-type transformer

A dry-type transformer, low-voltage coil technology, applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, etc. Limits, winding process difficulties and other problems, to achieve strong anti-sudden short-circuit ability, solve the problem of unrepairable, small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

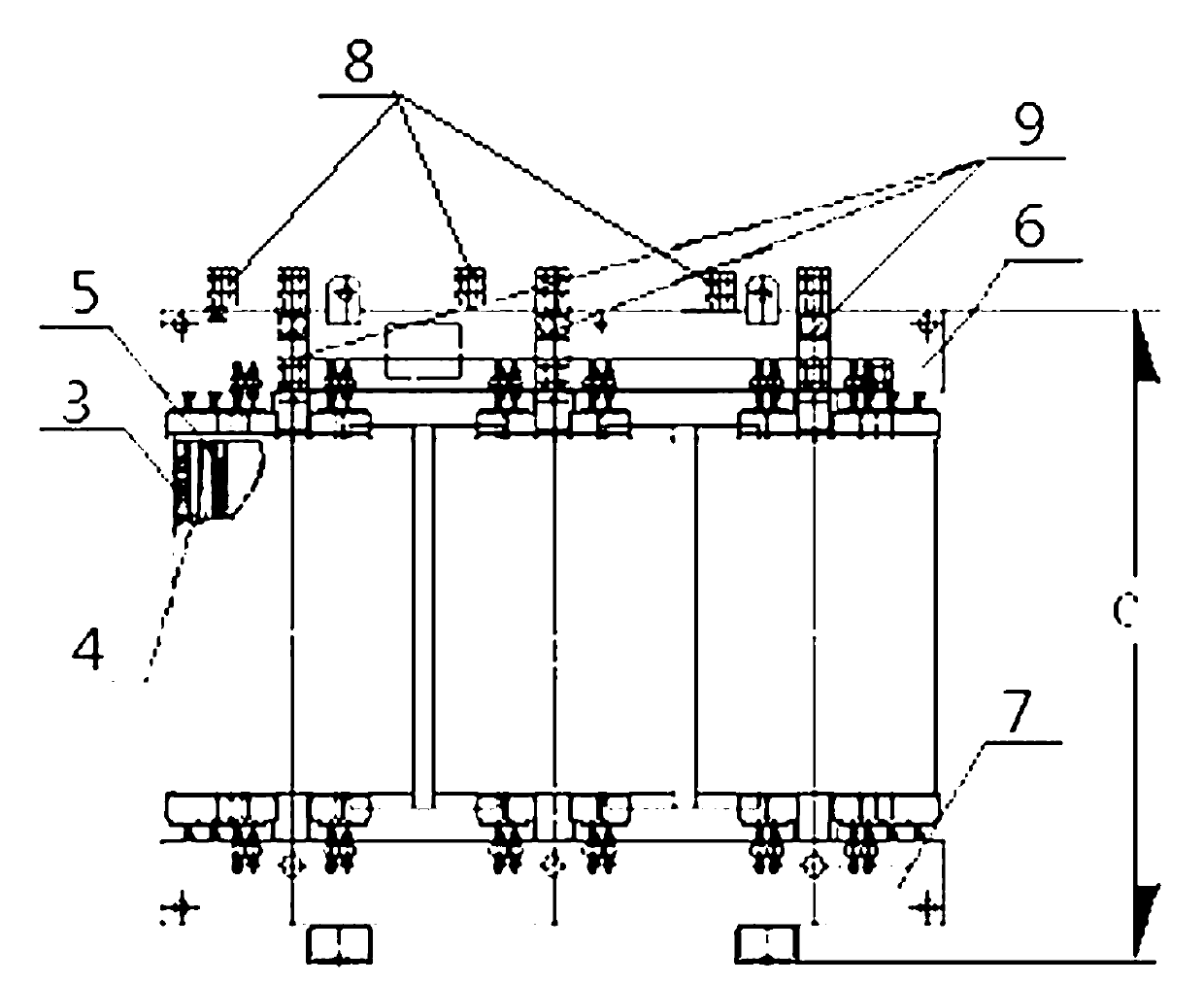

[0008] A dry-type transformer, comprising a housing 10, an iron core 1 is installed inside the housing 10, the iron core 1 is a three-phase three-column iron core, and the cross-sectional shape of the three core columns 2 of the iron core 1 is a rectangular open coiled iron core , there are two fractures 11 in each layer, and the positions of the fractures 11 are set on three core columns 2, and the three core columns 2 of the iron core 1 are filled with low-voltage coils 3, and the exterior of the low-voltage coils 3 is fastened with an insulating layer 4, A high-voltage coil 5 is installed outside the insulating layer 4 , an upper clamp 6 and a lower clamp 7 are fixed on the iron core 1 , and a high-voltage terminal 8 and a low-voltage terminal 9 are led out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com