Mixed-excitation synchronous motor with tripolar combination

A technology of hybrid excitation synchronization and combined magnetic poles, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous motors with rotating armatures and stationary magnets, magnetic circuits, etc., can solve difficult wide-range magnetic adjustment, Can not meet the problems of generator constant voltage operation, motor constant power and high power factor operation, etc., to achieve the effect of cost reduction, simple structure and small magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The three-pole combined magnetic pole hybrid excitation synchronous motor of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

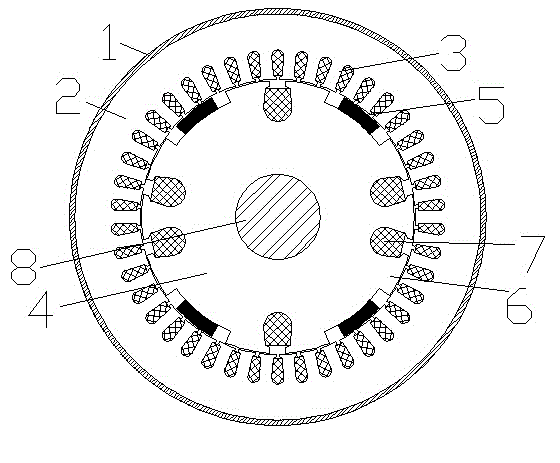

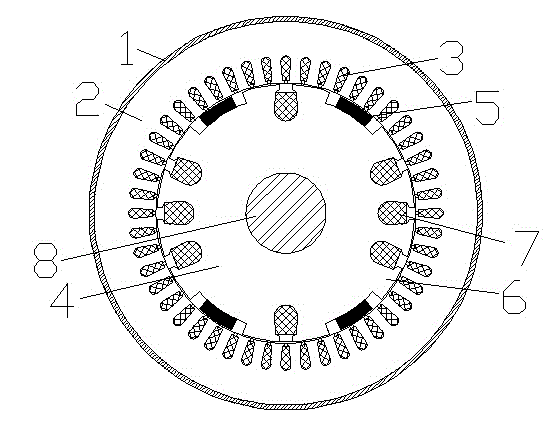

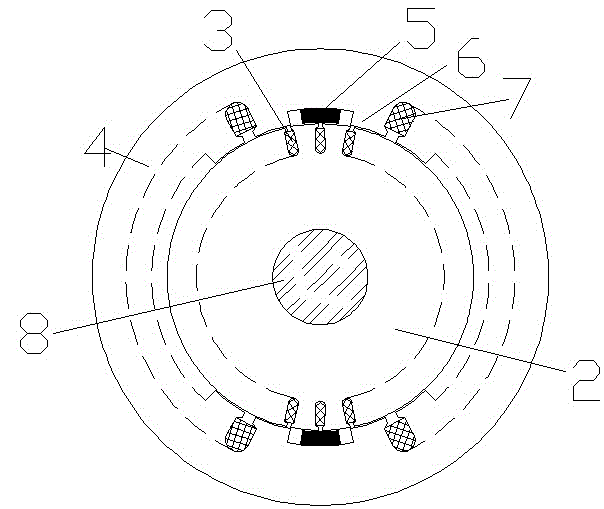

[0021] Depend on figure 1 , 2 It can be seen that the three-pole combined magnetic pole hybrid excitation permanent magnet motor of the present invention includes two parts: a stator with an armature winding and a rotor with a three-pole combined magnetic pole. The structure of the stator is the same as that of an ordinary motor. The armature windings are distributed in the stator slots, and the number of poles is the same as that of the rotor. When used as a generator, it is connected to the load, and as a motor, it is connected to the driving power supply. The magnetic circuit structure of the three-pole combination pole of the rotor pole is: the middle is a permanent magnet pole, the two sides are ferromagnetic poles, and there is no excitation winding i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com