Normal/radial parallel mixed excitation magnetic synchronization motor

A hybrid excitation synchronous and parallel technology, applied in the direction of synchronous machine components, etc., can solve the problems of difficult full adjustment of the main magnetic field, many air gaps in the magnetic circuit, complex structure, etc., and achieve convenient magnetic field adjustment, good fault tolerance performance, and high excitation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

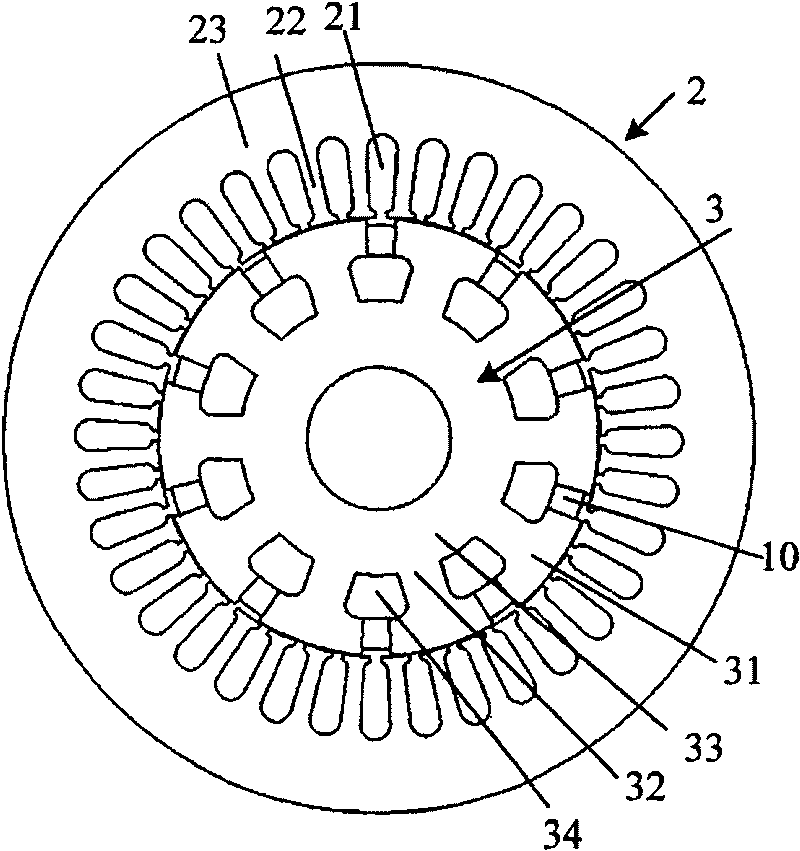

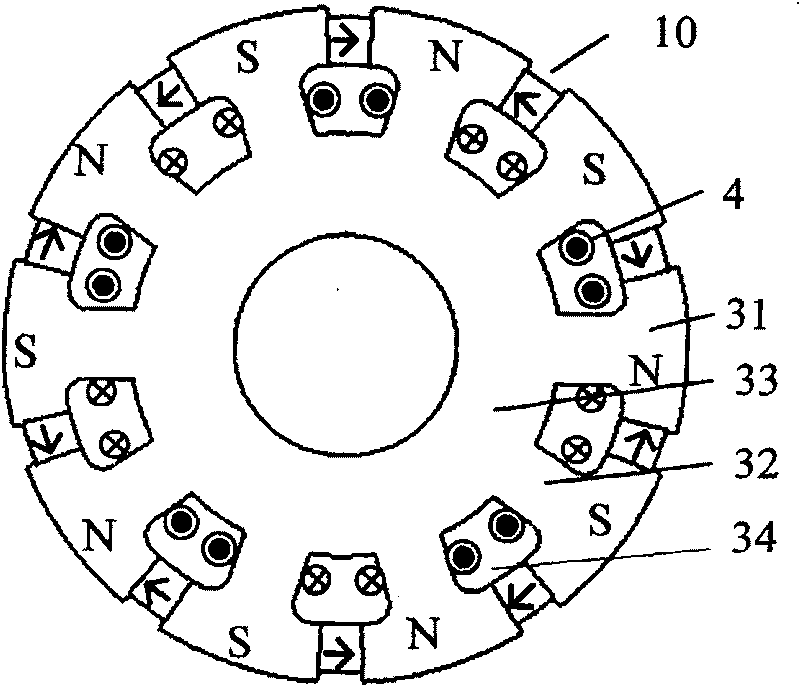

Embodiment Construction

[0018] There are many ways in which the tangential and radial parallel hybrid excitation synchronous motor of the present invention can be specifically realized: through the difference of the power supply of the excitation winding, it can be divided into separate excitation type and self-excitation type; according to whether there is a brush or not, it can be divided into brush type, Rotating rectifier type brushless excitation, etc., according to the different rotating parts, can be rotating magnetic pole type and rotating armature type; the stator core can be a salient pole structure or a hidden pole structure; the winding can be a distributed winding or a concentrated winding ;wait. For the sake of simplicity, a six-pair rotating magnetic pole type brushed synchronous motor is taken as an example to illustrate the specific implementation.

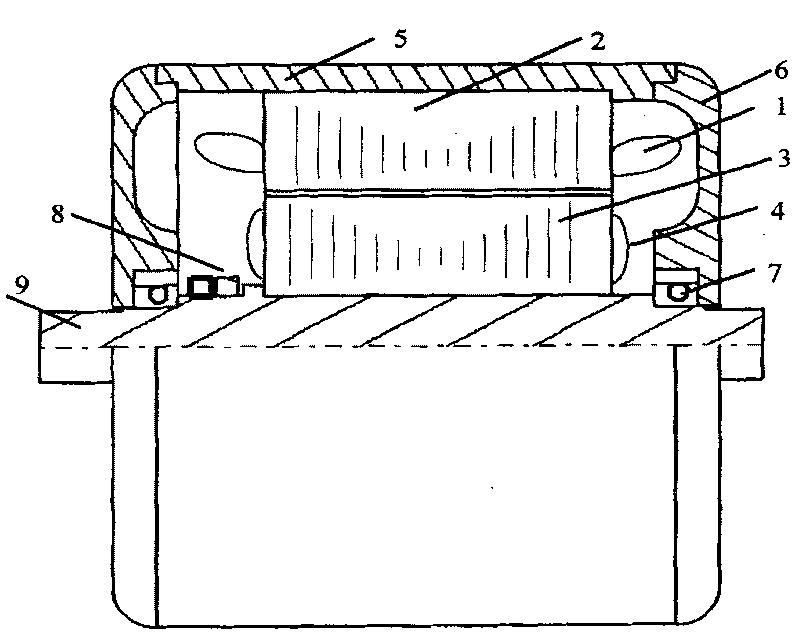

[0019] attached figure 1 The motor structure diagram of this scheme includes the stator and the rotor. The stator is composed of stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com