Microvoid wire threading locating mechanism

A positioning mechanism and wire threading technology, applied in fuse manufacturing and other directions, can solve the problems that the threading quality and product quality cannot be guaranteed, the fuse wire is easily deformed, and the accuracy and success rate are limited, so as to improve the efficiency of threading and threading. The effect of quality, compact structure and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

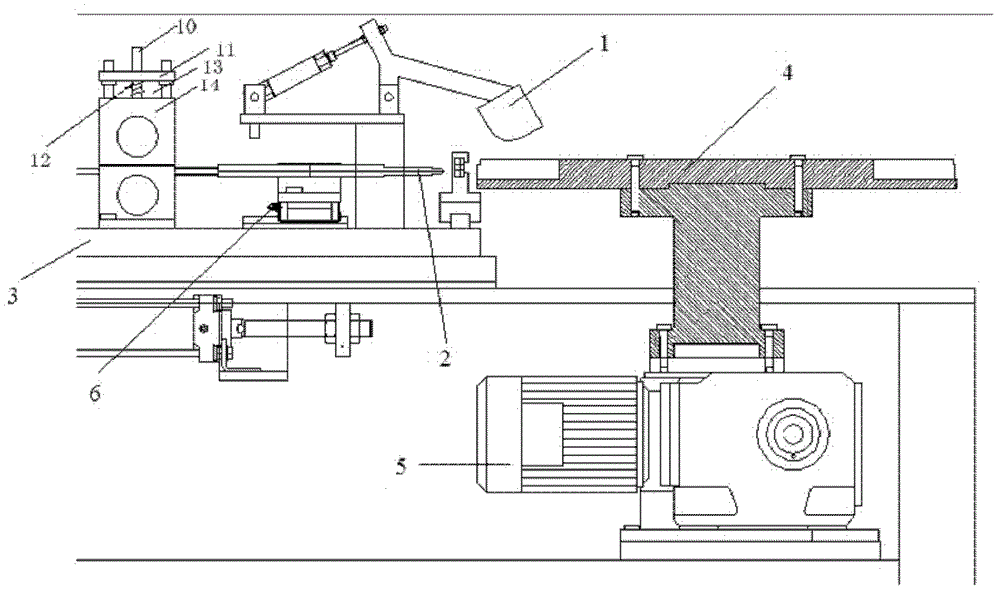

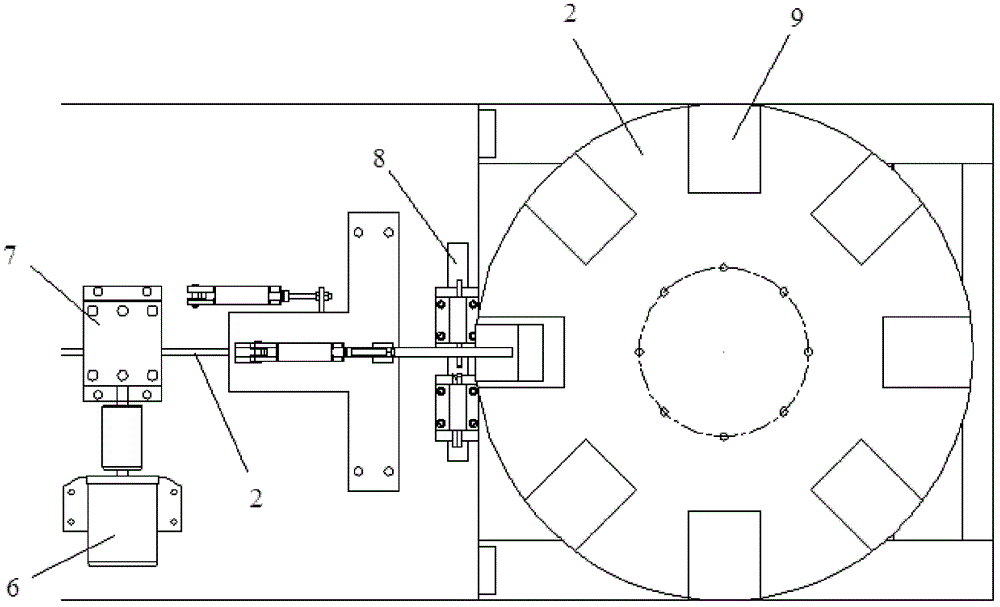

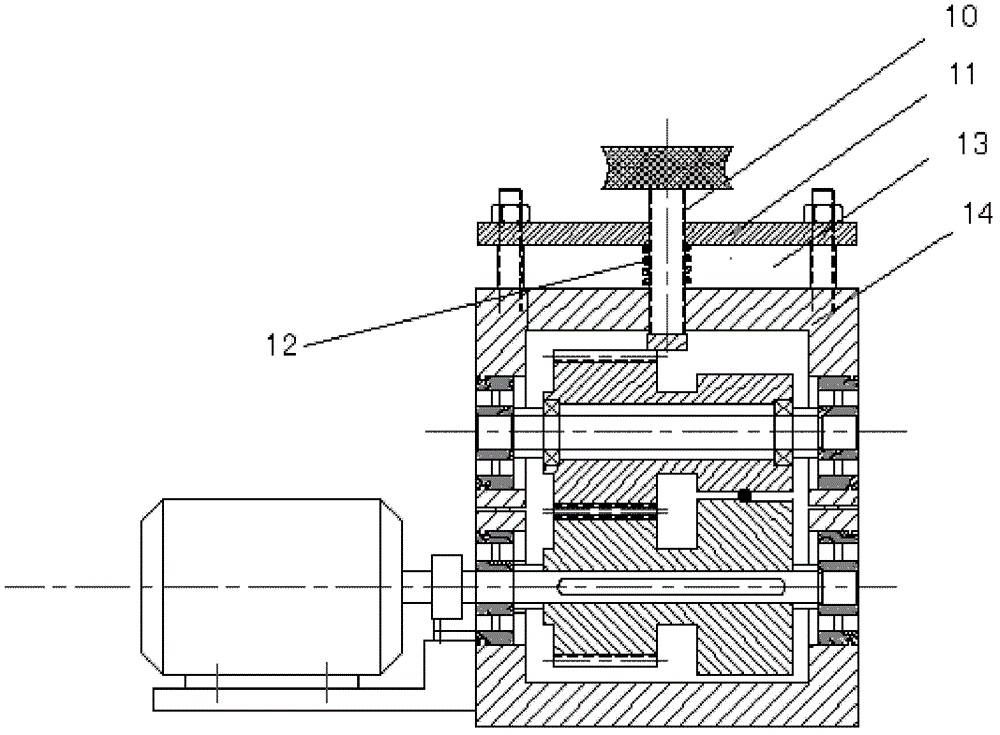

[0027] Such as Figure 1-2 As shown, a microhole threading positioning mechanism includes a turntable 4, a first motor 5, a capillary threading tube 2, a counter wheel wire feeding device, an upper cover plate 1, a negative electrode 8, a workbench 3, and a second motor 6 , the pair of wire feeding devices includes a pair of wire feeding rollers 7, a corresponding drive motor with the wire feeding rollers 7 and a controller for controlling the rotation angle of the driving motor, a pair of wire feeding rollers 7 as the main wheel and the slave The surface of the main wheel and the slave wheel are concave and convex, and the nominal diameters of the master wheel and the slave wheel are completely equal.

[0028] The lower end of the turntable 4 is provided with a stepping rotation mechanism, the upper end of the stepping rotation mechanism cooperates with the turntable 4, and the lower end is connected with the output shaft of the first motor 5, which is a stepping motor and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com