Method and equipment for removal of ceramic coatings by solid co2 blasting

A ceramic coating, CO2 technology, applied in the field of removing ceramic coatings and devices by solid CO2 spraying, which can solve the problems of low efficiency, damage to the substrate, long duration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

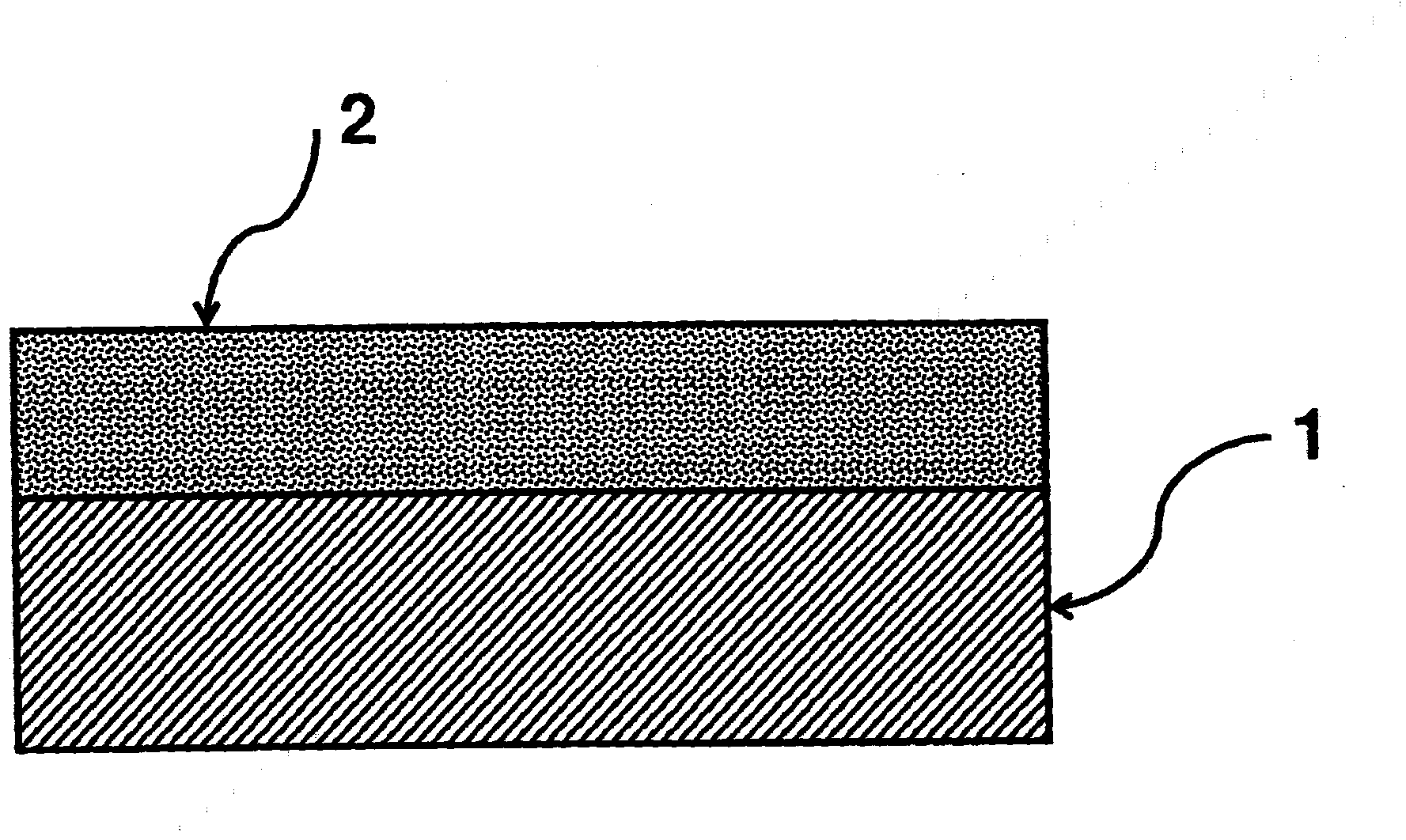

[0041] The present invention relates to a method and a device for removing a ceramic protective coating 2 (ie a thermal barrier coating such as yttria partially stabilized zirconia - YPSZ) with high removal efficiency and without compromising the properties of the substrate 1 .

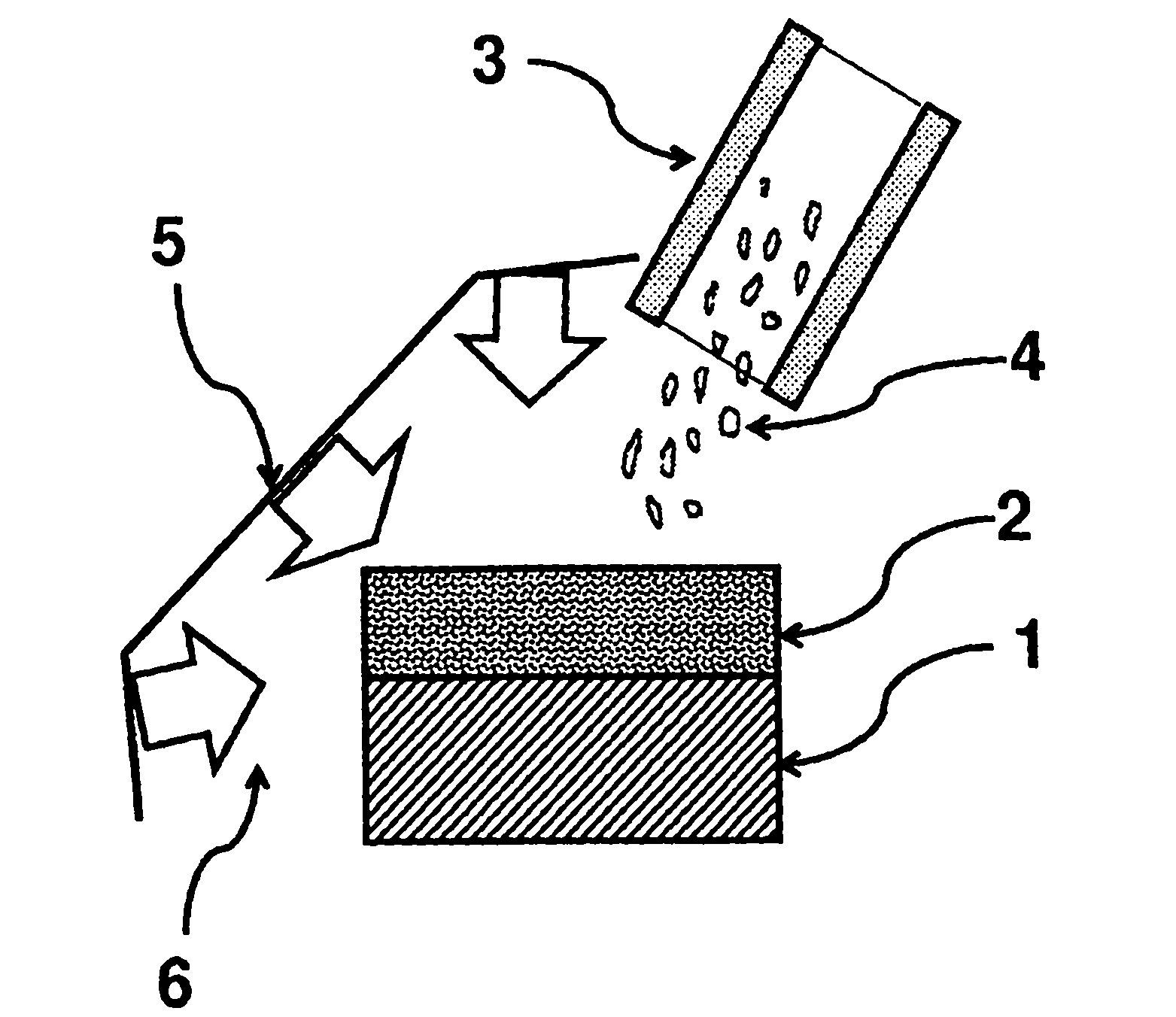

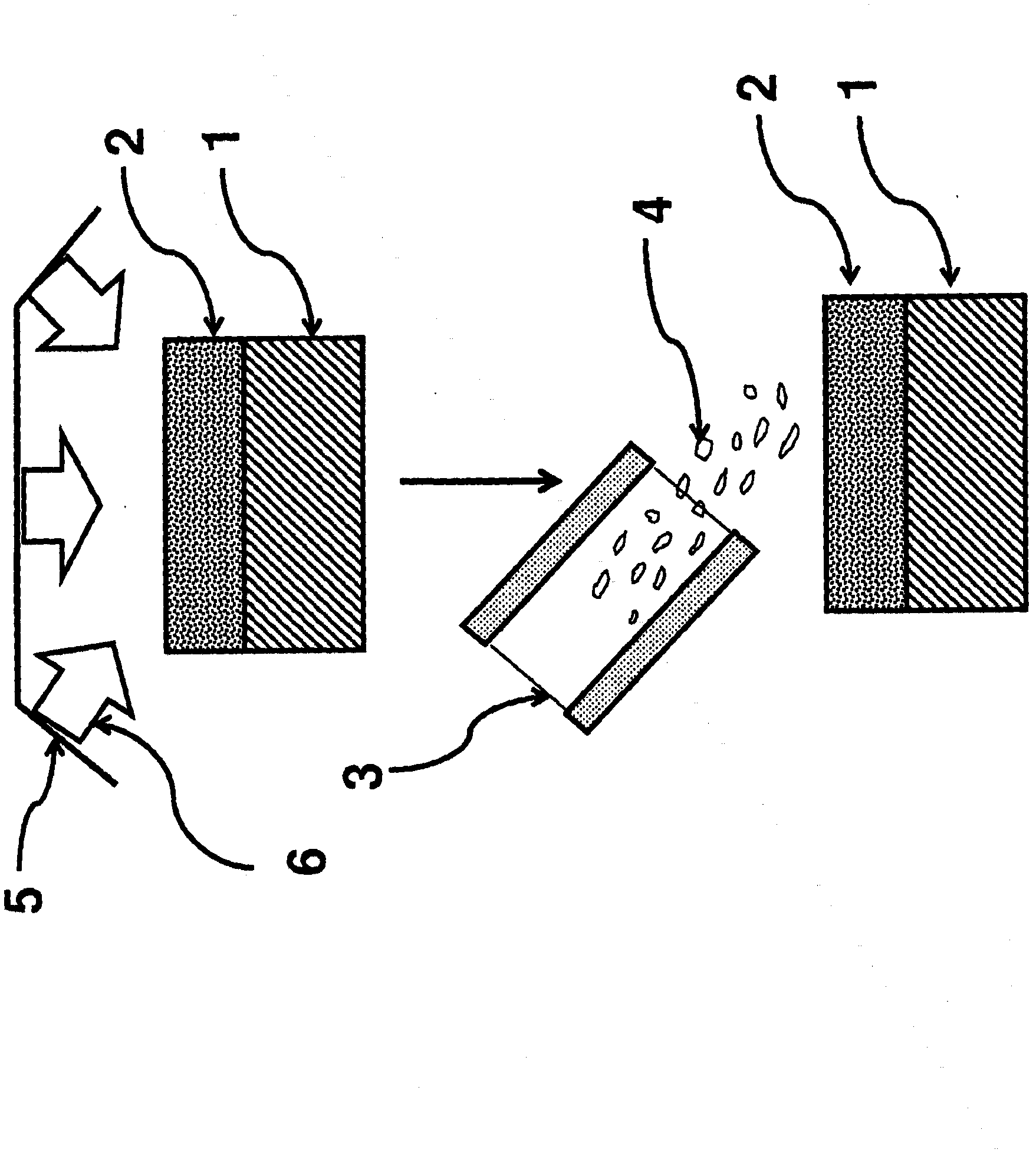

[0042] Removal of the ceramic coating 2 without compromising the properties of the substrate 1 was achieved by a combination of coating / substrate preheating by radiation and improved solid-state CO immediately before (Fig. 2(b)) or during (Fig. 2(a)) stripping. 2 4 injection parameters were obtained. Substrate 1 can be metal, ceramic, plastic or composite. Substrate properties not affected by the present invention are substrate thickness and roughness. The substrate thickness can vary from 1 μm to 1 m. The substrate can be rough (Ra > 9 μm) or smooth (Ra < 9 μm).

[0043] The stripping method is a single-stage process in which only solid CO 2 4 The combination of preheating during or immediately b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com