Non-reciprocal circuit element

A technology of circuit components and ferrite, which is applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of high manufacturing costs, difficult processing of openings, cracking, etc., achieve good mass production, ensure processing allowance, Effect of Good Temperature Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

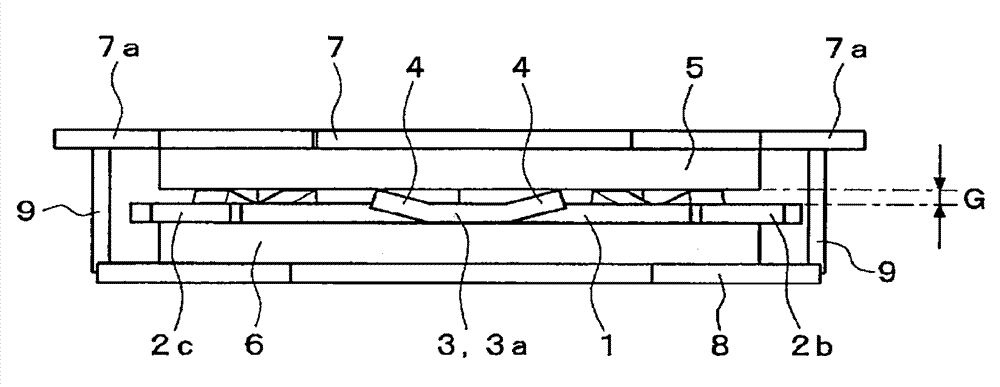

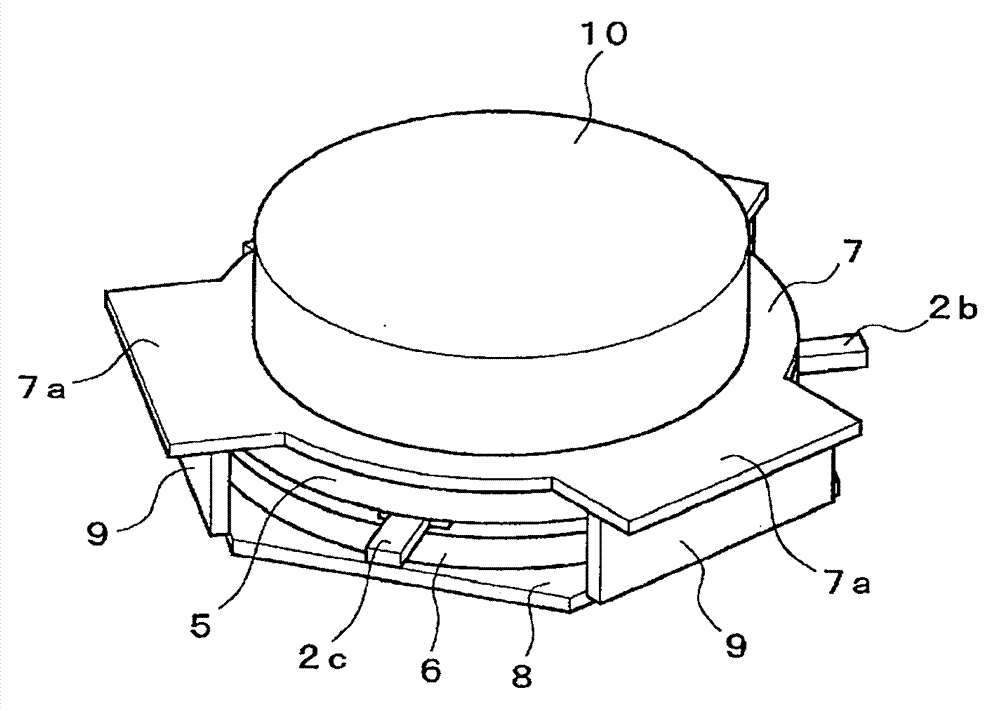

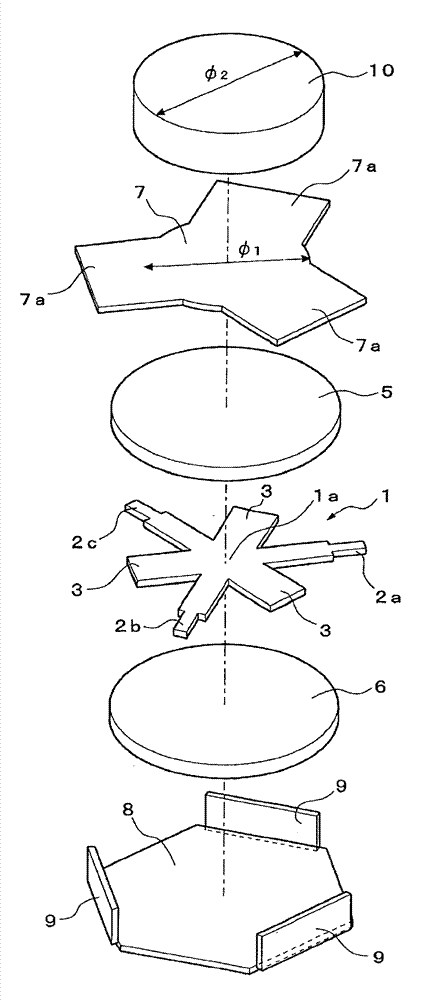

[0056] Figure 1 ~ Figure 4 It is a diagram showing an embodiment in which the non-reciprocal circuit element according to the present invention is applied to an isolator, and the reference numeral 1 in the figure is a center conductor.

[0057] The center conductor 1 is formed of a metal plate such as phosphor bronze, and has input and output terminals 2a, 2b, and 2c that extend radially in three directions from the center portion 1a toward the outside. Here, the input and output terminals 2a, 2b, and 2c have a center angle of 120° between each other, and are formed in a Y-shape as a whole. Between the input and output terminals 2a, 2b, and 2c adjacent in the circumferential direction, they are respectively formed facing outwards. Resonator 3 that extends radially. In addition, the resonator 3 is set to have a shorter length dimension than the input / output terminals 2a, 2b, and 2c.

[0058] In addition, each resonator 3 is formed in a T-shape by forming a protruding portion at it...

no. 2 Embodiment approach )

[0080] Figure 7 ~ Figure 9 This is a diagram showing the second embodiment in which the non-reciprocal circuit element according to the present invention is applied to an isolator. Similar to the above-mentioned first embodiment, the reference numeral 1 in the figure is a center conductor.

[0081] The center conductor 1 is formed of a metal plate such as phosphor bronze, and has input and output terminals 2a, 2b, and 2c that extend radially in three directions from the center portion 1a toward the outside. Here, the input and output terminals 2a, 2b, and 2c have a center angle of 120° between each other and are formed in a Y-shape as a whole. Between the input and output terminals 2a, 2b, and 2c adjacent in the circumferential direction, they are formed with the same outward facing Square resonator 3 extending radially. In addition, the resonator 3 is set to have a shorter length dimension than the input / output terminals 2a, 2b, and 2c.

[0082] In addition, the center conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com