Optical fiber connector in which Bragg grating is built

A Bragg grating and fiber optic connector technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems such as differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to express the features and advantages of the present invention more clearly, the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0078] Embodiments of the present invention are described below.

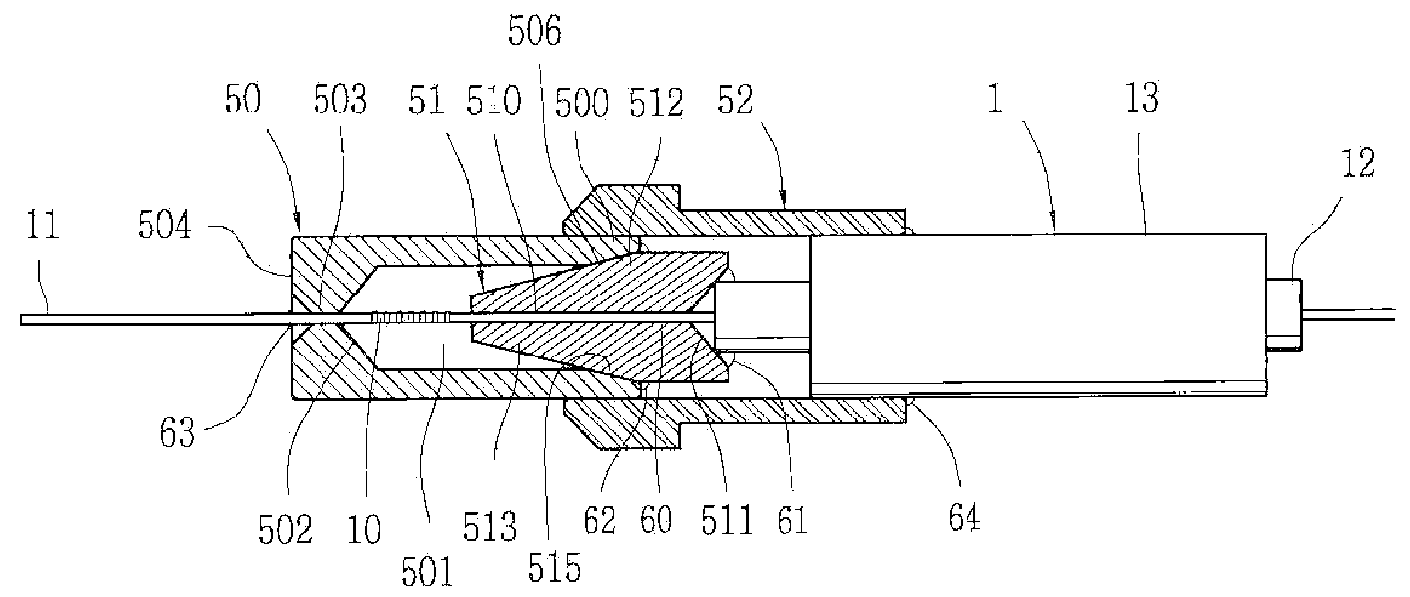

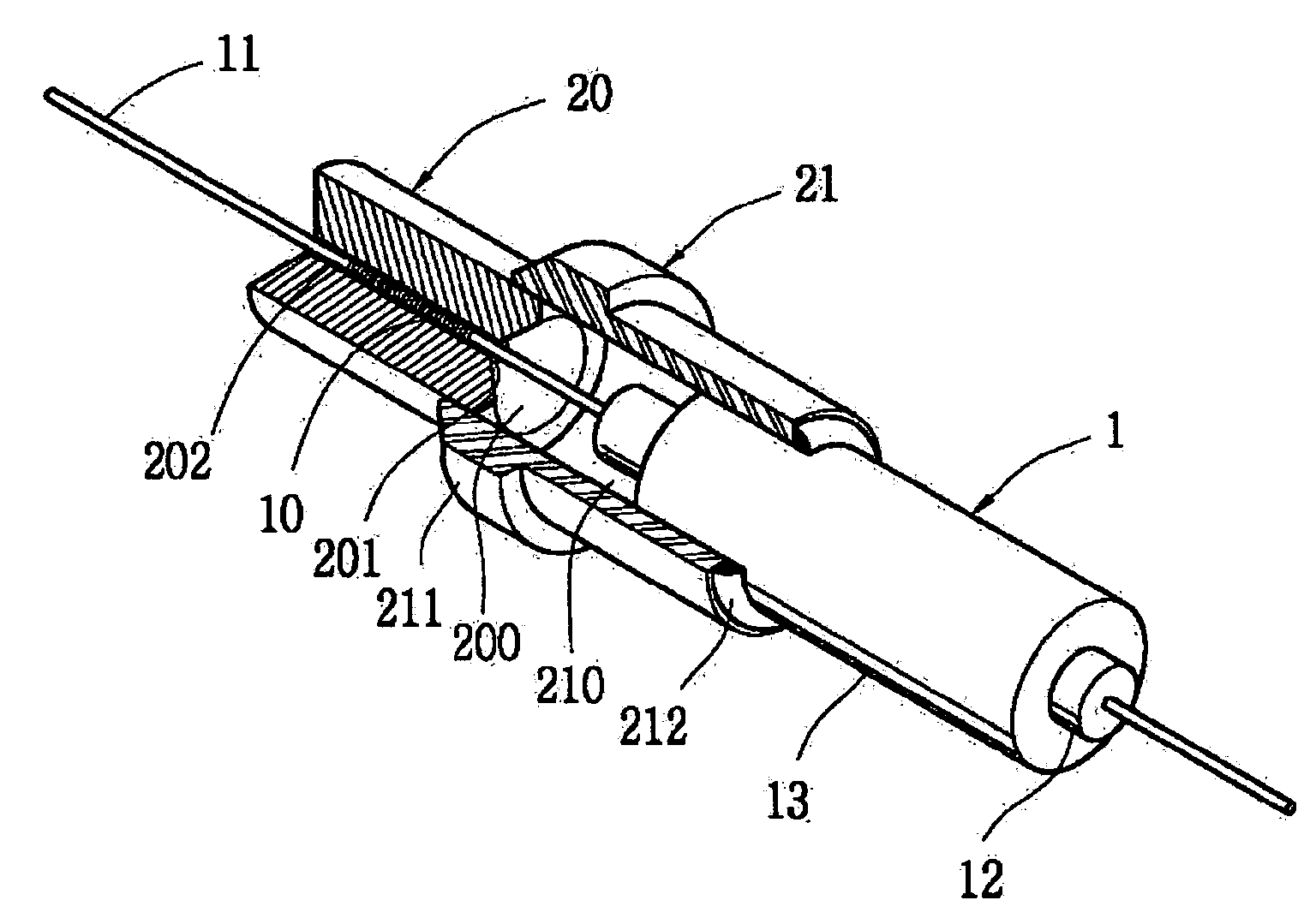

[0079] Figure 5 It is an exploded oblique view of the internal structure of the fiber optic connector with built-in fiber Bragg grating according to the embodiment of the present invention, Image 6 yes means Figure 5 The state of the component structure.

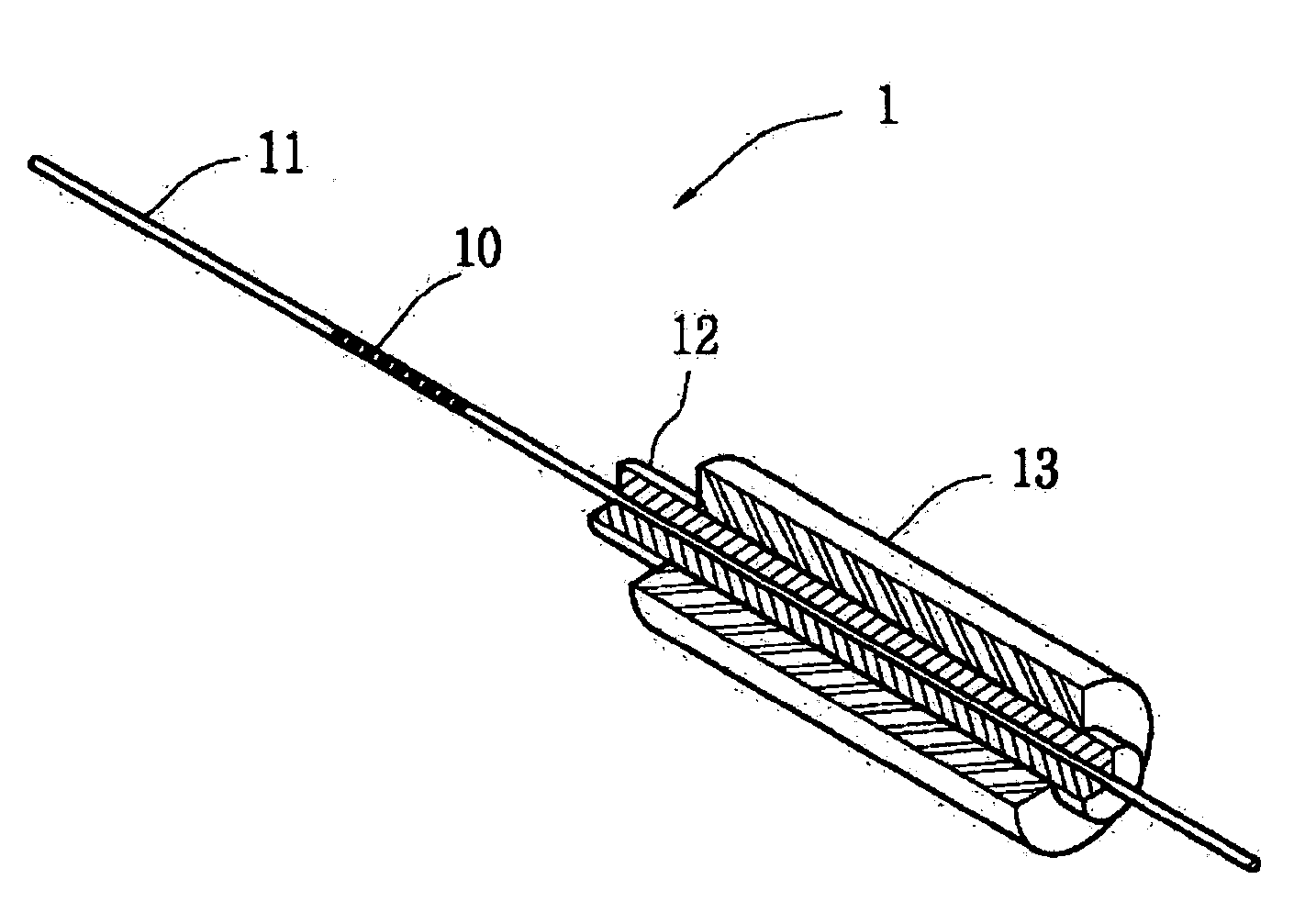

[0080] The optical fiber cable 1 has a known structure and its composition includes: an optical fiber 11 forming a Bragg grating 10; an optical fiber coating 12 formed with a polymer material to protect the Bragg grating 10 and the optical fiber; and an optical fiber coating 13 made of a polymer material .

[0081] The optical fiber connector 5 of the present invention is composed of a ferrule 50 , a connection port 51 for temperature compensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com