Rice storage bin device special for natural ventilation cooling in the process of rice processing

A natural ventilation and cooling technology, applied in the field of grain storage warehouses, achieves the effects of no energy consumption, low cost, and reduced broken rice rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

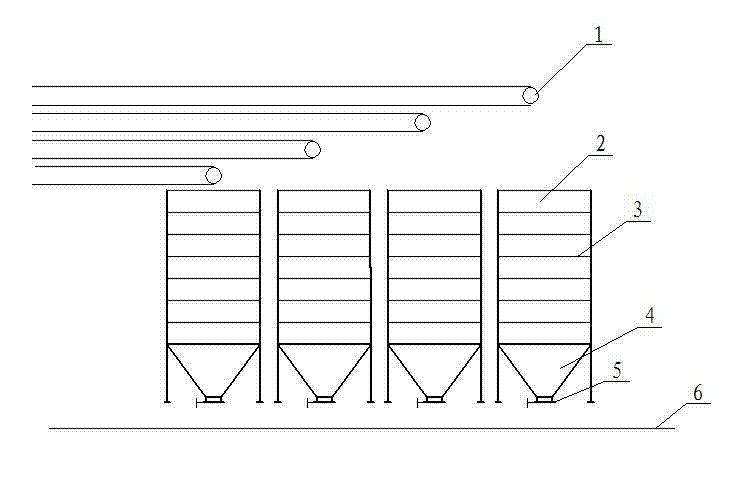

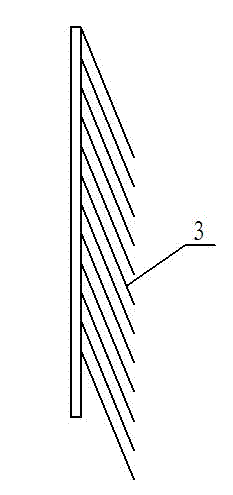

[0009] The specific implementation of the special rice storage bin device for natural ventilation cooling and cooling in rice processing according to the present invention will be described with reference to the accompanying drawings: its composition includes an upper conveyor belt 1, a bin body 2, a louvered bin wall 3, a bin Bottom funnel 4, valve 5, lower delivery tank 6. The bin body 2 is made into a square or rectangular or polygonal shape, and the volume of each bin body is 20-60 tons. The top of the bin is open, and a rice conveyor belt 1 is arranged above each bin top, and the lower end of the bin body 2 is set as a funnel at the bottom of the bin. 4. A valve 5 is provided at the bottom of the funnel 4 of the bin body, and a lower conveying trough 6 is respectively arranged under the valve 5, and each bin body 2 is arranged vertically and horizontally with the bin body 2 to form a bin body array group, and each bin body 2 is connected with the bin body The body is an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com