Airflow purification production line special for sericite

A technology of sericite powder and production line, which is applied in the field of airflow purification production line for sericite powder, can solve the problems of wasting sericite raw ore, electricity and labor, poor product purity, and affecting product quality, so as to improve performance and product quality, wind power The effect of maintaining stable strength and improving thickness stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

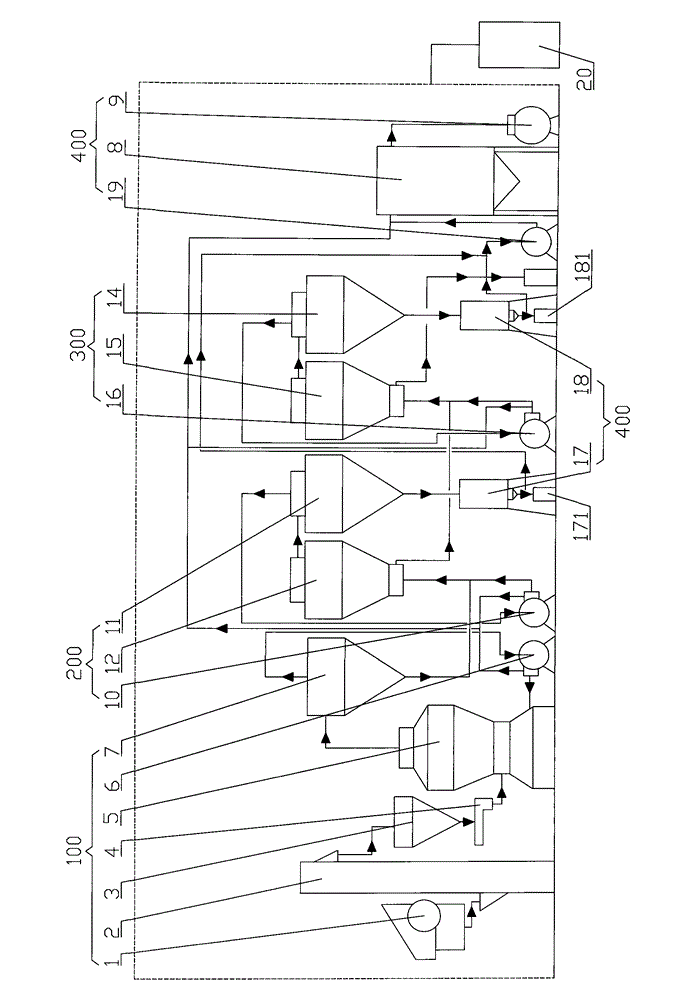

[0014] Examples, see figure 1 Shown: Sericite powder special airflow purification production line, including grinding system 100, purification system 200, classification system 300, dust removal system 400, iron removal system and electric control system. In this way, a relatively complete production line has been formed, and several important links in the production of sericite powder have been considered.

[0015] The following systems are optimized:

[0016] The grinding system 100 includes: a jaw crusher 1 , a bucket elevator 2 , a storage tank 3 , a feeder 4 , a pendulum mill 5 , a first air blower 6 and a powder collecting box 7 . Wherein, the air outlet at the front end of the first air blower 6 sends air to the pendulum mill 5, the upper part of the pendulum mill 5 communicates with the powder collecting box 7, and the upper part of the powder collecting box 7 communicates with the first blower 6 backend pipeline. In this way, the sericite raw ore is crushed to a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com