Automobile gearbox shell body pressure casting technology

A technology of automobile transmission and die-casting technology, which is applied in the field of die-casting technology, can solve the problems of being unsuitable for automobile lightweight, low product qualification rate, and harsh production environment, and achieve the effects of improving the production environment, beautiful appearance, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

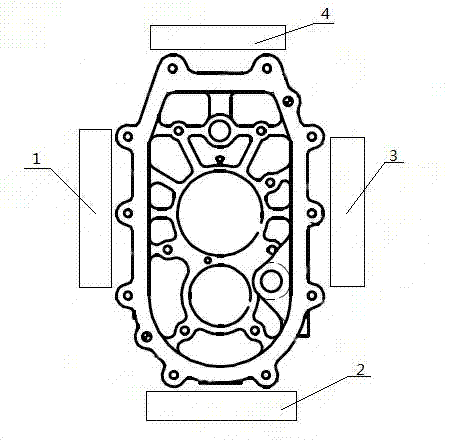

[0024] Such as figure 1 As shown, the present invention provides automobile transmission housing die-casting process, comprises the following steps:

[0025] Step 1: Preparation before die-casting, including raw material inspection, storage, protection, smelting and aluminum water transportation;

[0026] Step 2: Die-casting process, that is, first spray a layer of release agent on the surface of the die-casting mold; then insert the core-pulling, the sequence of core-pulling insertion is: live block → front slider 2 and rear slider 4 → left slider 1 and right Slider 3; the next step is to close the mold; after the mold is closed, the injection starts; after the injection is completed, the mold is opened; Slider 3 → front slider 2 and rear slider 4; finally take out the blank, and use the ejector device to eject the loose block, wherein, the range of system pressure in this step is: 14MPa~16MPa, and the range of injection time It is: 9s~10s, the range of mold opening time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com