Strip workpiece cutting device and cutting method

A strip-shaped workpiece and cutting device technology, which is applied in the direction of shearing device, cutting forming blank device, manufacturing tools, etc., can solve the problems of easy deformation of the cutting end, affecting the work efficiency of the production line, and generating sawing debris, etc. , to achieve the effect of stable cutting action, small workpiece deformation and high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

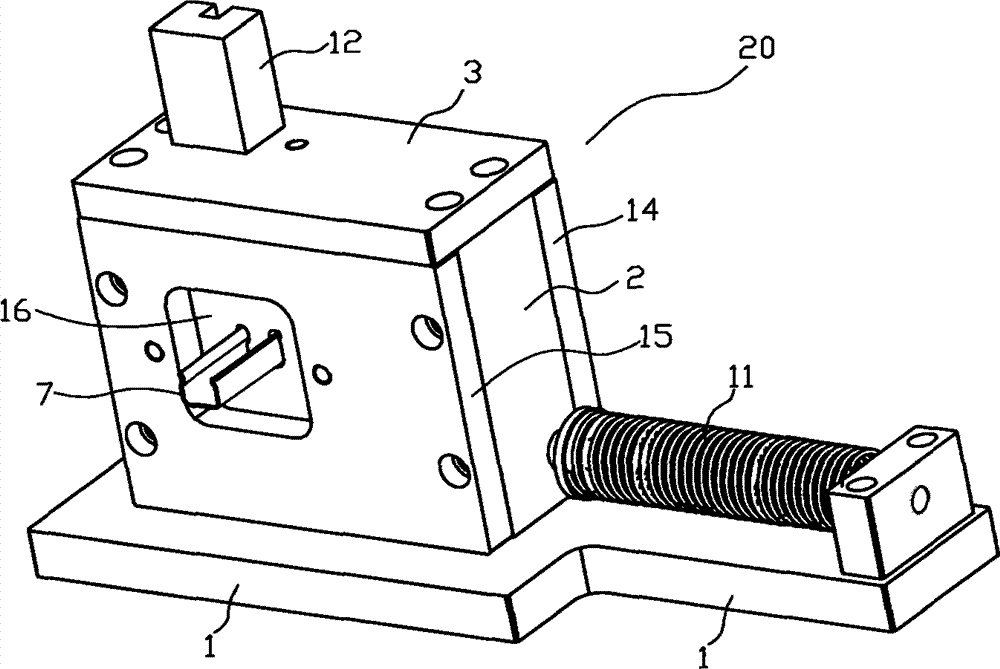

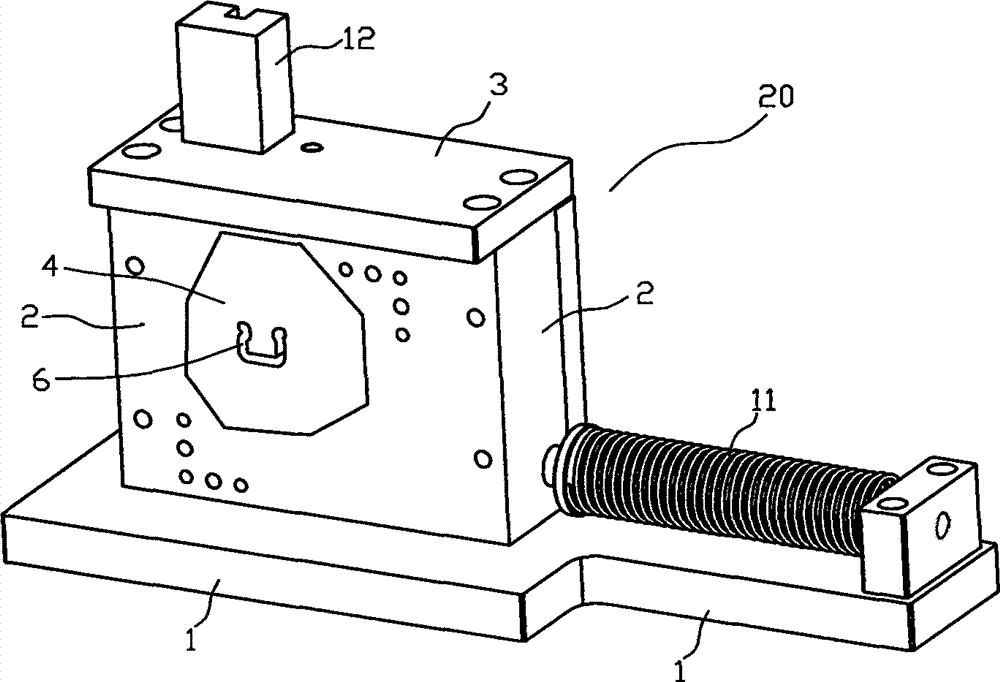

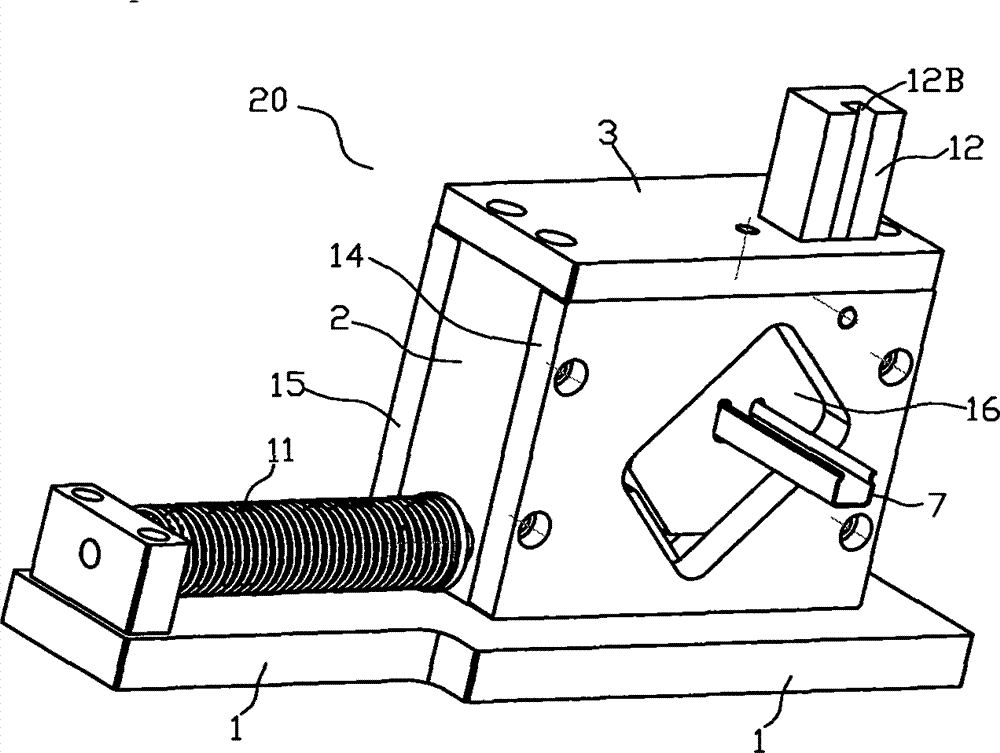

[0038] Such as Figure 1 to Figure 6 As shown, the strip-shaped workpiece cutting device 20 of the present invention includes a base plate 1, a mold frame 2 fixedly installed on the base plate 1, an upper cover plate 3 fixedly installed on the formwork frame 2, and a front and rear panel positioned under the upper cover plate 3. The fixed module 4 and the moving module 5 are closely stacked together, and the middle position of the fixed module 4 and the moving module 5 is provided with a workpiece passage 6, and the cross-sectional shape of the workpiece passage 6 is similar to that of the strip-shaped workpiece 7; the fixed module 4 is fixed Installed in the formwork 2; the moving module 5 is an entity extending along its cross section, and its cross section is a polygon including at least four inclined working sides, forming smooth upper left working slopes, lower left working slopes, upper right working slopes, The lower right working inclined surface, wherein, the upper le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com