Robot joint actuator with soft feature

A robot joint and driver technology, applied in the field of service robots, can solve problems such as the inability to meet robot requirements, and achieve the effects of easy processing, energy saving, and protection of human-machine safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

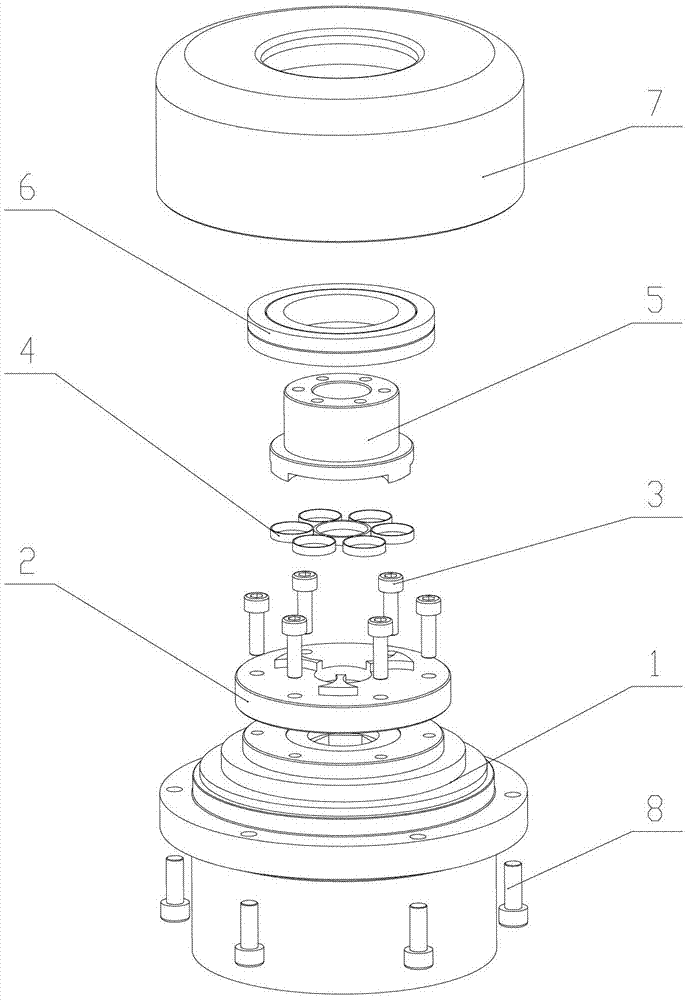

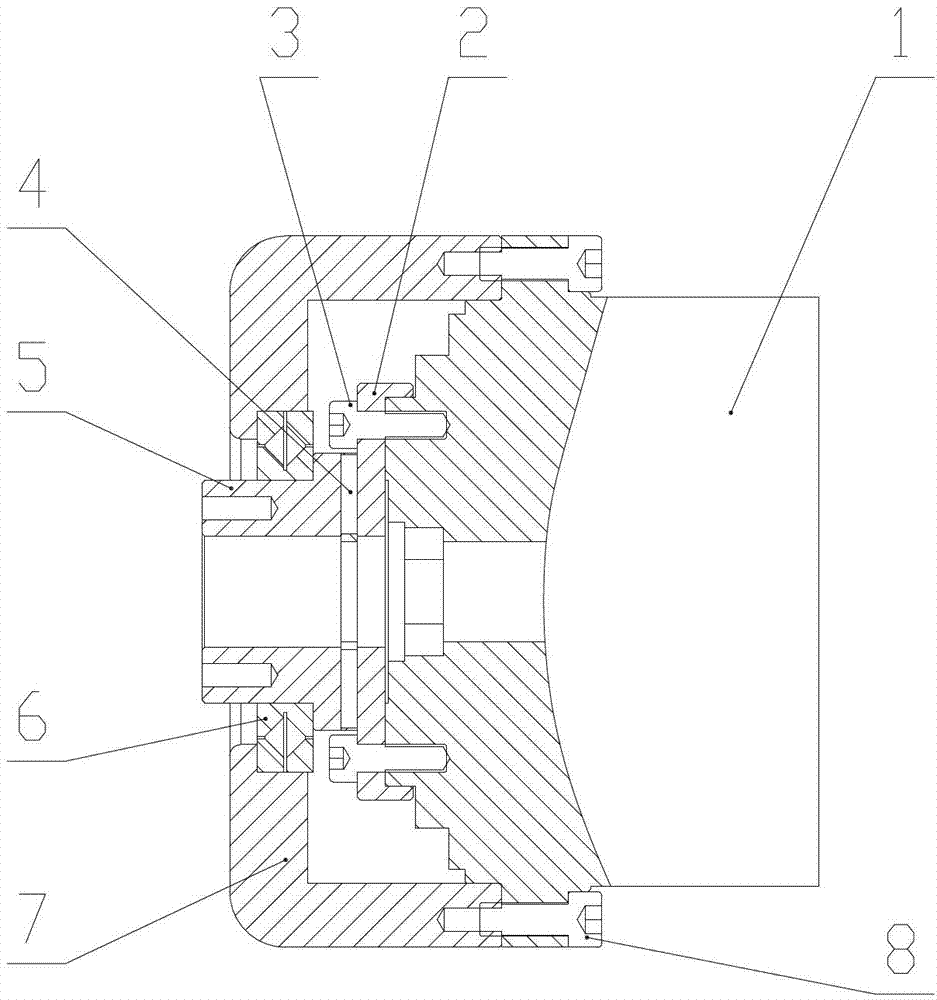

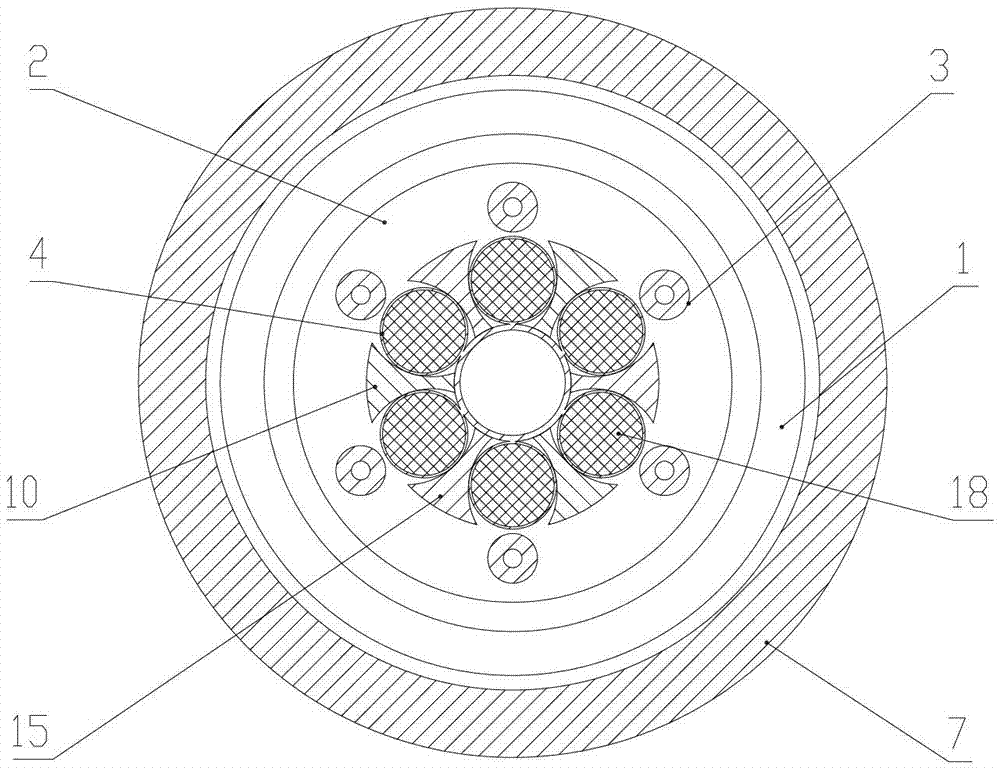

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

[0020] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a harmonic reduction motor 1, an input turntable 2, a screw 3, a flexible part 4, an output shaft 5, a crossed roller bearing 6, an outer shell 7, and a screw 8; The end face of the geared motor 1 is positioned and fixed with screws 3 and through holes 9, see Fig. 4(a) and Fig. 4(b); The sides of the three evenly distributed fan-shaped bosses 10 are close to each other, and ensure that the threading hole 12 and the base ring 13 are coaxial, see Figure 5 (a) and Figure 5 (b), to position and install the flexible part 4; use auxiliary The mounting part 19 squeezes the thin-walled ring 14 to cause a radial displacement of several millimeters, so that the fan-shaped boss 15 on the output shaft 5 is pressed into the positioned flexible part 4 between the thin-walled rings 14, see Figure 8 (a) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com