An automatic cutting machine

A cutting machine, automatic technology, used in thin material processing, metal processing, sending objects and other directions, can solve the problems of low accuracy, low efficiency, easy to occur safety accidents, etc. order, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

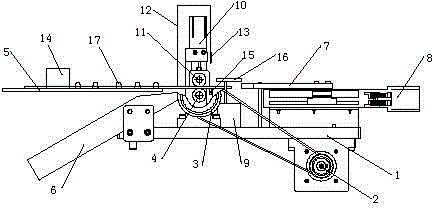

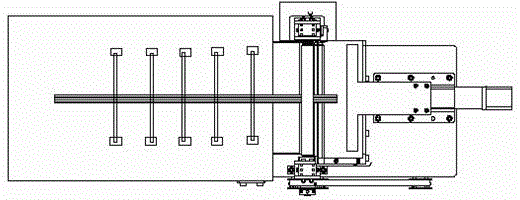

[0016] Combine below Figure 1 to Figure 3 Specific description embodiment:

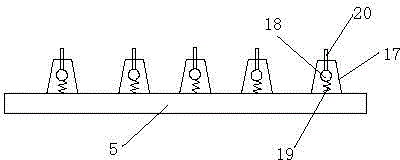

[0017] An automatic cutting machine, comprising a frame 1, the frame 1 is provided with a feed motor 2, the feed motor 2 is connected with a runner 3, and the runner 3 is connected with a driving roller 4, One side of the driving roller 4 on the frame 1 is provided with a rod release plate 5, and the bottom of the driving roller 4 is located at a side of the rod release plate 5 and is provided with a waste material outlet groove 6; the frame 1 The other side of the driving roller 4 is provided with a sliding limit plate 7, the sliding limiting plate 7 is connected with the limit motor 8 through a threaded rod, and a Outlet chute 9; said frame 1 is provided with cylinder 10 at both ends of driving roller 4, said cylinder 10 is connected with driven roller 11, and said driven roller 11 is under the effect of cylinder 10 It can be clamped and fed with the driving roller 4; the frame 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com