Movable stand shifting device

A technology of mobile device and movable stand, which is applied in the direction of lifting device, lifting frame, etc., can solve the problems of high manufacturing cost and complex structure of the movable stand, and achieve the effects of low manufacturing cost, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

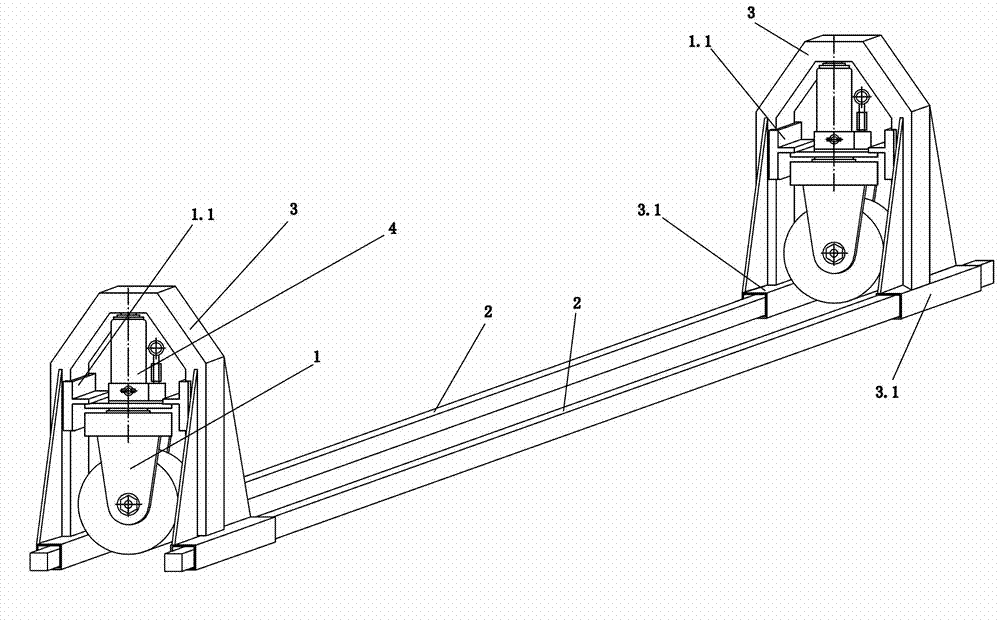

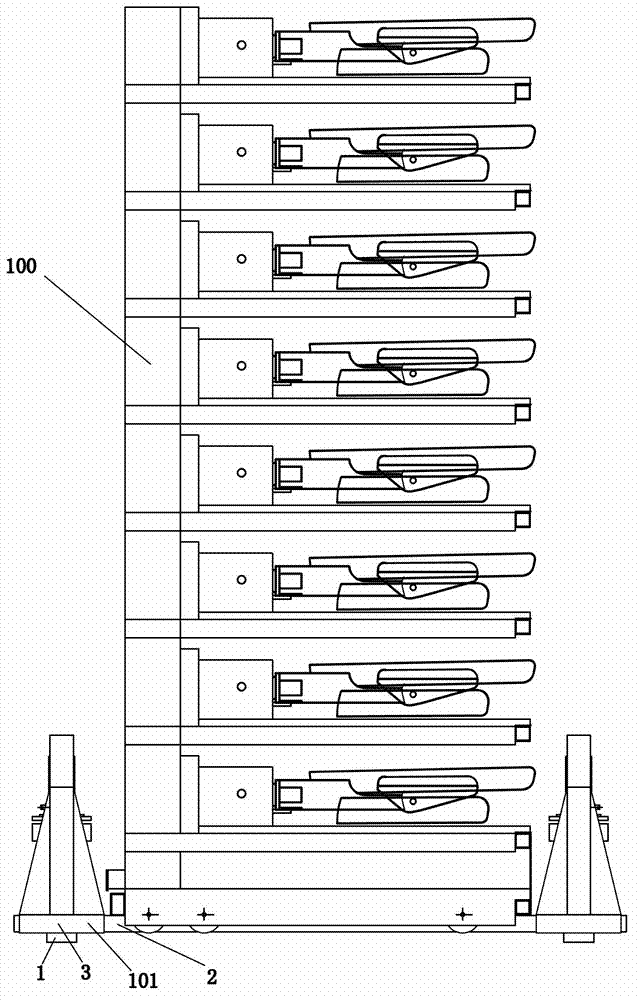

[0019] like figure 1 As shown, the present invention comprises caster 1, support bar 2, support bar frame 3 and jack 4; Each caster 1 is equipped with a support bar frame 3 and a jack 4 to form a walking foot; The outline is square, the bracket 3 is an inverted U-shaped part, the piston of the jack 4 is fixedly connected with the middle part of the upper end of the bracket 3, the base of the jack 4 is fixedly connected with the wheel frame of the caster 1; The lower ends of the sides are respectively provided with a supporting rod connection hole that is movable with the supporting rod; every two walking feet and two supporting rods 2 parallel to each other are combined to form a walking frame, and the two ends of each supporting rod are connected with two supporting rods respectively. The lower end o...

Embodiment 2

[0021] The difference between the second embodiment and the first embodiment is that the guide 1.1 of the second embodiment is a vertical rod, the lower end of which is fixedly connected with the wheel frame of the caster (1), and the upper end is connected with the guide provided at the upper end of the bracket (3). Hole slip fit.

Embodiment 3

[0022] The difference between the third embodiment and the first embodiment is that the guide piece 1.1 of the third embodiment is a slider piece adapted to the vertical guide groove provided on the inner surface of the side of the bracket (3), and the number of pieces is two. Correspondingly, the inner surfaces of the two sides of the bracket (3) are provided with a vertical guide groove.

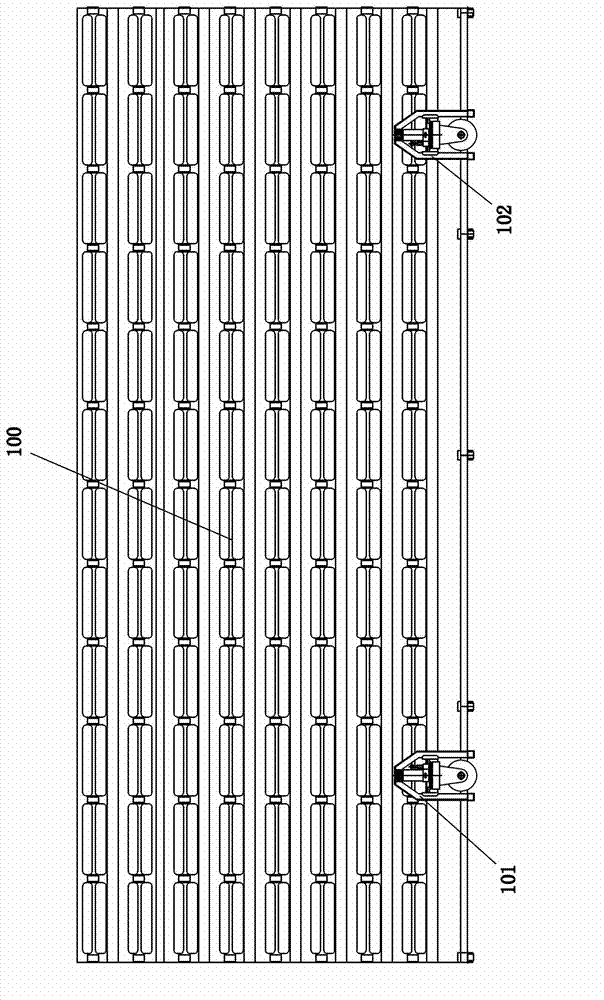

[0023] In the above embodiments, the square tube-shaped support rod can be replaced by a circular tube-shaped support rod, and the corresponding support rod connecting hole is replaced by the inner hole of the circular tube 3.1 welded to the lower ends of the two sides of the support rod frame 3. Form, now when the walking feet are socketed with the two round pipes, a connecting rod should be used to connect the two round pipes to prevent the round rods from rolling. In addition, the two support rods in the above embodiments can also be replaced by a support rod with a U-shaped plug joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com