Sand baking device for quartz sand

A technology of quartz sand and baking sand, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of environmental pollution, high energy consumption, rising dust, etc. The effect of installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

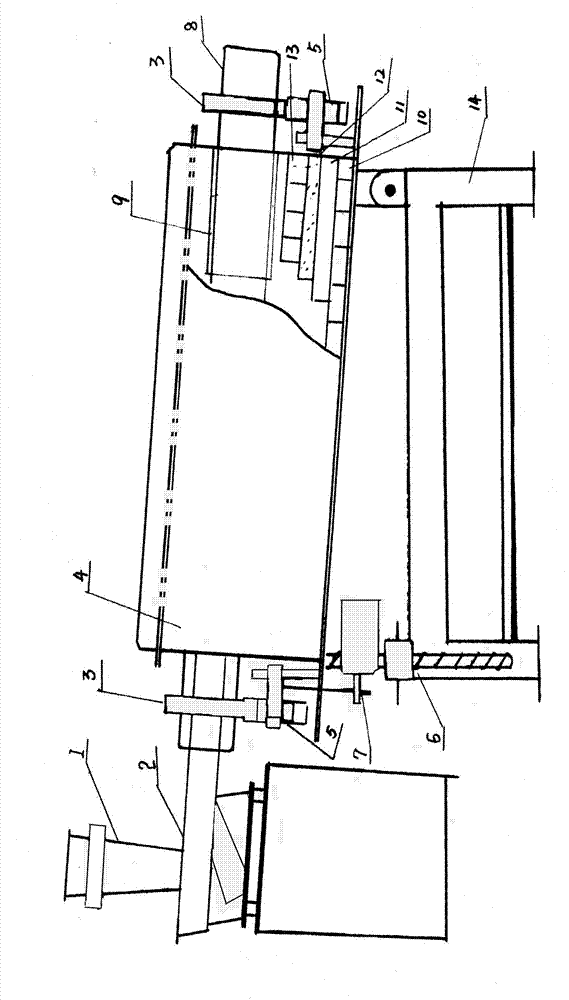

[0016] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0017] refer to figure 1 , a sand-baking device for quartz sand, comprising a sand-baking box 4 installed on a bracket and inclined downwards, the inclination angle of the sand-baking box 4 is 20°-60°, and the sand-baking box 4 outputs The bottom of the end is hinged on the bracket, and the bottom of the input end of the sand baking box 4 is fixedly connected to the bracket through the inclination lifter 6. The inclination lifter 6 can be a screw driven by a motor. When the angle of the sand baking box 4 needs to be adjusted, only The input side of the sand baking box 4 can be lifted or lowered by lifting or lowering the screw rod, thereby adjusting the inclination angle of the sand baking box 4 .

[0018] At least two quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com