Hollow ultrahigh template section steel platform and construction method thereof

A technology of section steel and formwork, which is applied to the ultra-high reinforced concrete horizontal component construction platform and its construction field, can solve the problems such as the difficulty of formwork erection, achieve the effect of convenient working space, reduce investment and speed up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

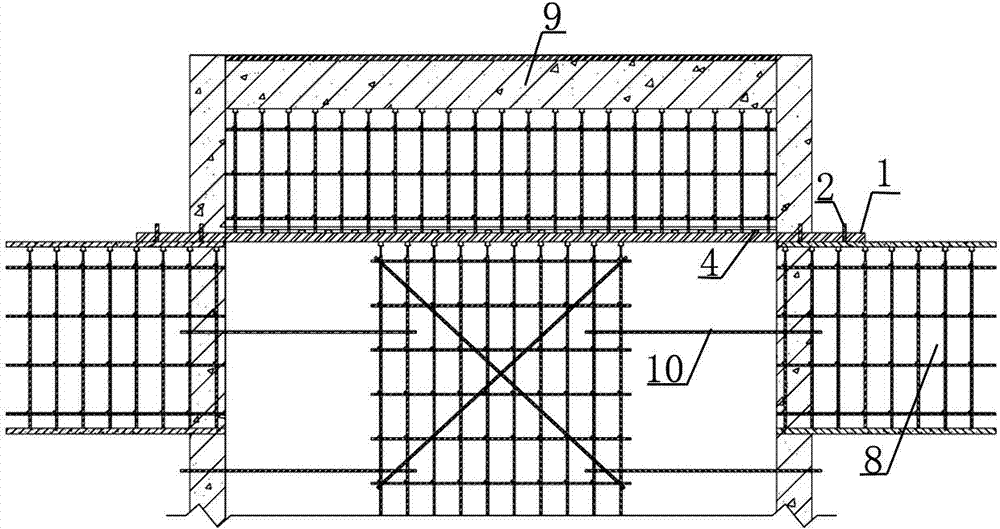

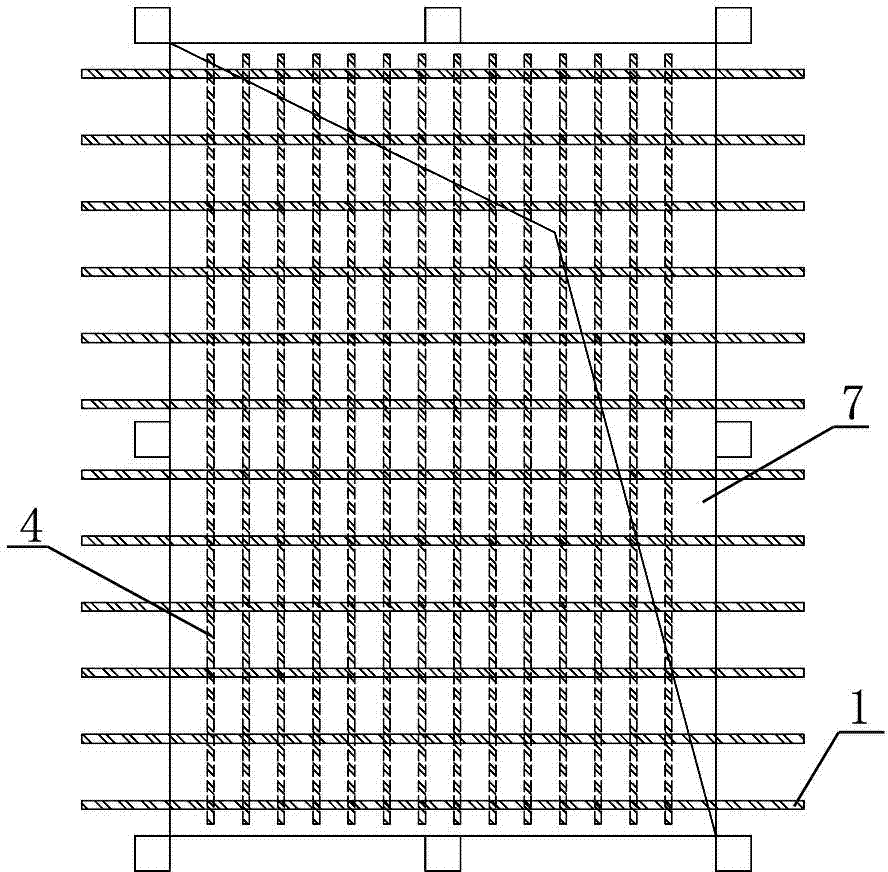

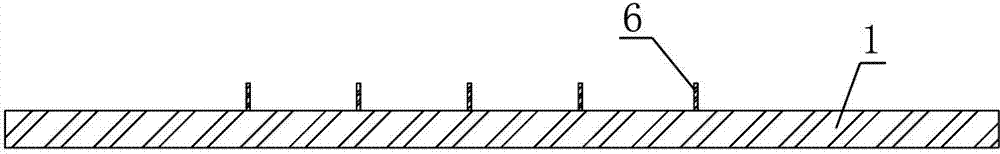

[0027] Examples see Figure 1 to Figure 3 As shown, a hollow super-high formwork steel platform on which a formwork scaffold 5 is erected, including a transverse steel beam 1, a longitudinal steel beam 4, a scaffold board 7, a supporting scaffold 3 and at least two lower formwork platforms of the same height 8. The two ends of the transverse steel beam 1 are erected on the two lower formwork platforms 8 respectively, and fixed by the end fixture 2, and the longitudinal steel beam 4 is erected vertically on the transverse steel beam 1, and It is fixedly connected with the transverse steel beam 1, and the scaffold board 7 is laid on the plane formed by the interweaving of the longitudinal steel beam 4 and the transverse steel beam 1, and the support scaffold 3 is supported under the plane, and the support scaffold 3 and the lower formwork platform 8 Pull the knot through the pull rod 10.

[0028] The transverse steel beam 1 and the vertical steel beam 4 are I-shaped steel beams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com