Extraction device and method utilizing microwave coal heating layer

A microwave heating and coal seam technology, applied in safety devices, mining fluids, mining equipment, etc., can solve the problems of low-permeability coal seams that cannot achieve the effect, affect the safe and efficient production of coal mines, and long drainage time, etc., to increase the penetration of coal seams performance, speed up the desorption speed, and increase the effect of gas pressure

Inactive Publication Date: 2013-05-22

刘永杰

View PDF9 Cites 46 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since most of the coal seams in my country belong to low-permeability coal seams, this kind of negative pressure drainage cannot achieve the ideal effect on low-permeability coal seams, and the drainage time is long, which affects the safe and efficient production of coal mines.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

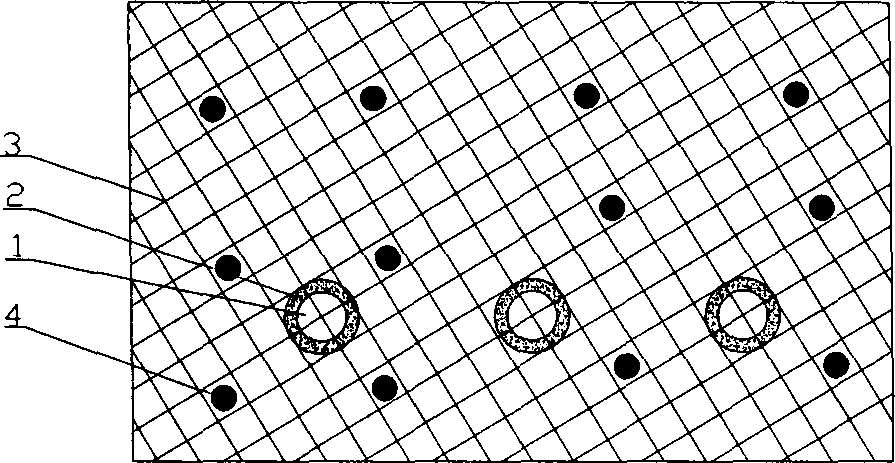

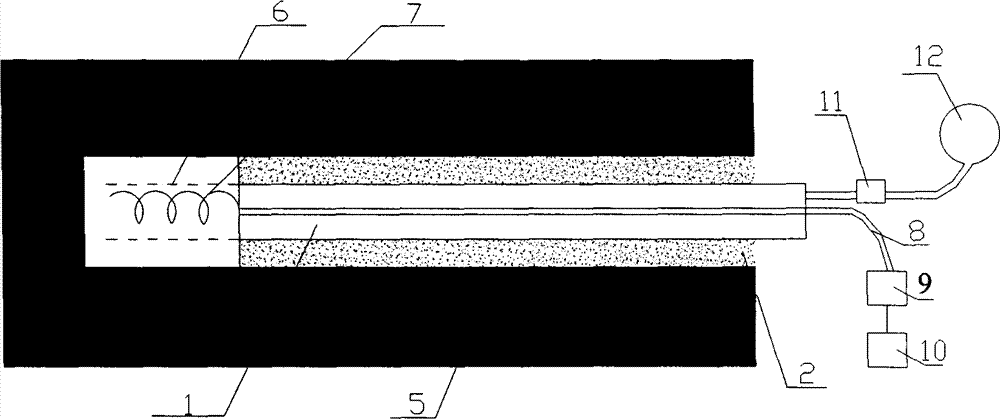

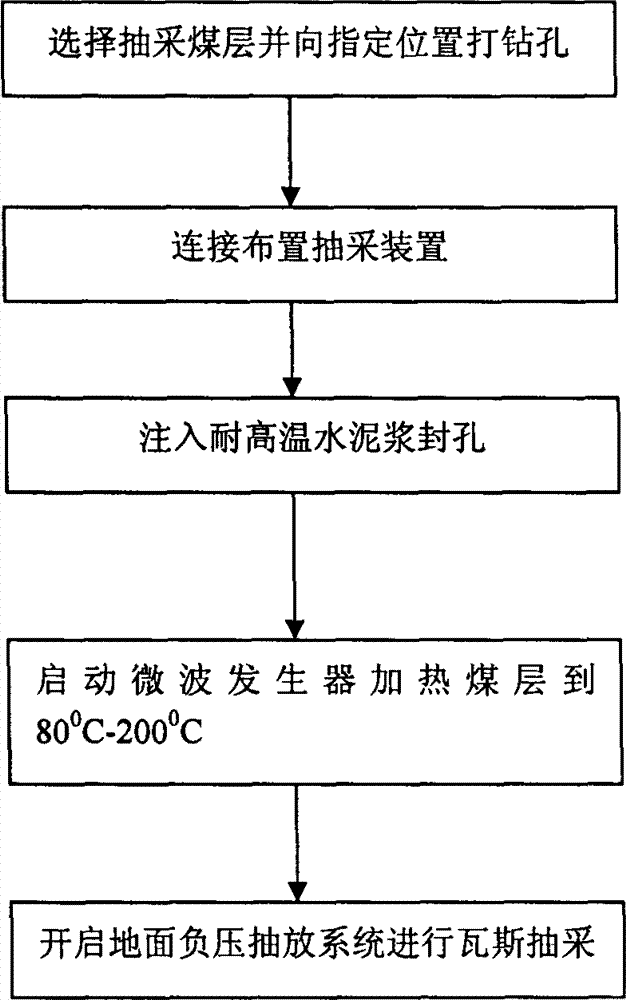

Disclosed are extraction device and method utilizing a microwave coal heating layer. The extraction device mainly comprises an extraction and drainage pipe (1), a helical antenna (7), a front-loaded cover (6), a cable (8), a microwave generator (9), a controller (10), a cooling device (11), a gas exhaust pipe (12) and the like. The problems of low extraction rate and extraction speed of existing extraction methods are solved. The extraction method is characterized by including: firstly drilling a hole at an appointed position of an extraction coal layer, paving an anchorage net on the surface of the extraction coal layer and drilling a drill rod to reinforce the coal layer; placing the extraction and drainage pipe with the helical antenna into the drilled hole by the distance 0.6-1.0m away from the coal layer, sealing the hole by high-temperature-resistant cement grouting, and starting the microwave generator to heat the extraction coal layer to the temperature of 80-200 DEG C. After the coal layer is heated, desorption speed of gas is increased, the free gas is increased to cause increase of gas volume of the coal layer, so gas pressure is increased and gas extraction rate of gas of the coal layer in the negative-pressure extraction drilled hole is increased favorably.

Description

technical field [0001] The invention relates to a drainage device for heating coal seams by using microwave technology, which belongs to the technical field of coal bed gas extraction and is suitable for gas drainage in high-gas and low-permeability coal seams. Background technique [0002] Most coal mines in my country are high-gas mines, and coal and gas outbursts, gas explosions and other disasters are serious natural disasters in coal mining. With the gradual increase of mine mining depth and scale, the gas content of coal seams gradually increases, and Disasters are also becoming more and more serious, not only affecting the safe and efficient production of coal mines, but also threatening the safety of mine personnel, seriously affecting the safe production of coal mines and the sustainable and stable development of the economy in my country. [0003] At present, high-gas mines must carry out gas drainage on the coal seam before mining. The main drainage methods are gro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21F7/00E21B43/24

Inventor 刘永杰李永冲赵倩廖俊生王冉庆苏飞

Owner 刘永杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com