Efficient drum type heat exchanger

A heat exchanger and barrel type technology, which is applied in the field of high-efficiency barrel heat exchangers, can solve the problems of low heat exchange efficiency and poor heat exchange effect, so as to improve the heat exchange efficiency, increase the flow path, and prolong the flow path. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

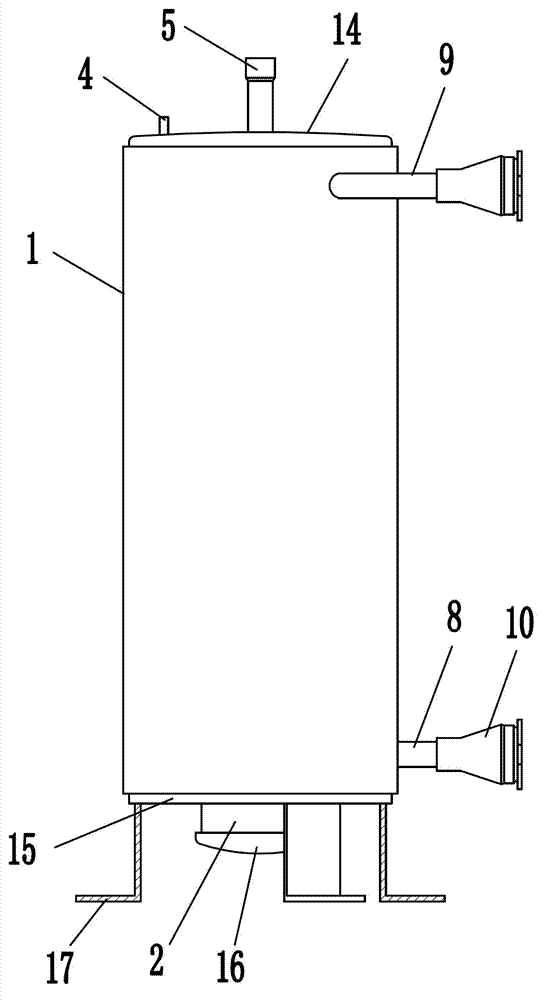

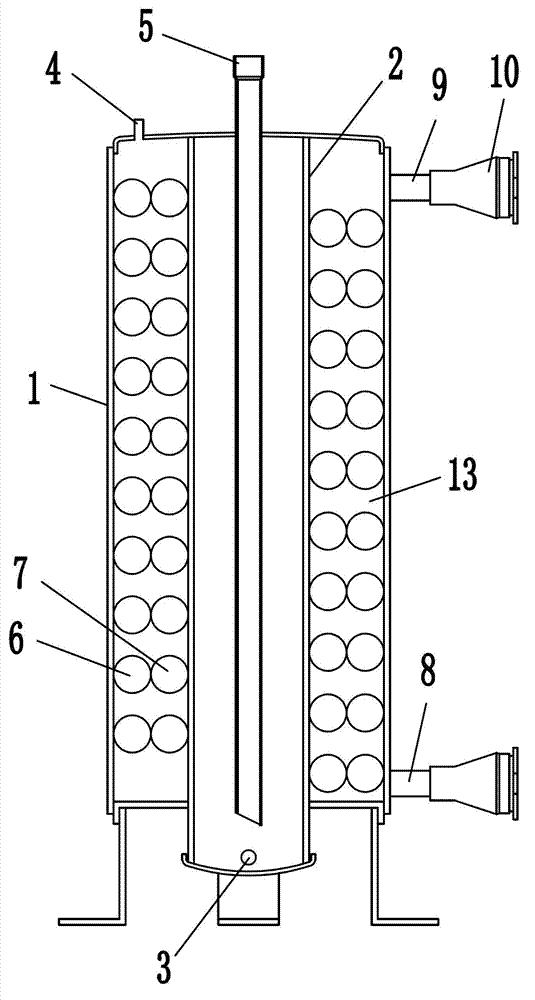

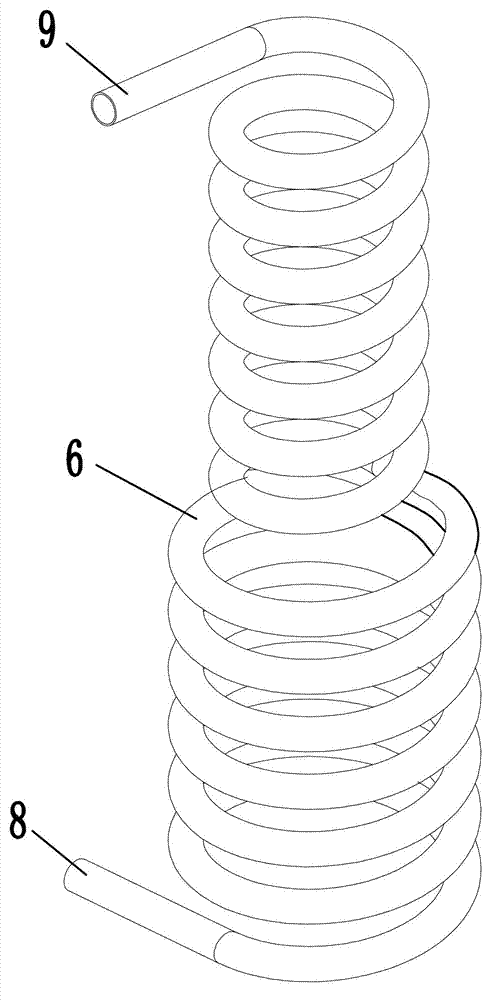

[0027] Embodiment 1: as figure 1 , 2 As shown, a high-efficiency cylindrical heat exchanger includes an outer cylinder 1, and a fixed foot 17 is fixedly installed on the bottom of the outer cylinder 1. The middle part of the outer cylinder 1 is fixed with an inner cylinder 2, and an annular cavity is formed between the inner cylinder 2 and the outer cylinder 1. The upper end cover of the outer cylinder 1 has an upper cover 14, and the lower end cover has a lower cover 15. The lower end of the inner cylinder 2 Covered with a head 16. The bottom end of the inner cylinder 2 has two through holes 3 distributed oppositely, and the inside of the inner cylinder 2 communicates with the outside of the inner cylinder 2 through the through holes 3 . There is a refrigerant inlet 4 on the top of the outer cylinder 1, and a refrigerant outlet 5 on the top of the inner cylinder 2. The refrigerant inlet 4 communicates with the cavity between the outer cylinder 1 and the inner cylinder 2, an...

Embodiment 2

[0033] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 9 As shown, two coil groups are installed in the cavity between the outer cylinder 1 and the inner cylinder 2 , and both coil groups include a first helical coil 6 and a second helical coil 7 . The two sets of coils are connected sequentially, and the two coils are in contact with each other, and the outer coil is in contact with the inner surface of the outer cylinder 1, and the inner coil is in contact with the outer surface of the inner cylinder 2. The part of the coil group between the outer cylinder 1 and the inner cylinder 2 forms a refrigerant channel 13 .

[0034] When the width of the part between the outer cylinder and the inner cylinder is the same, using two coils for each coil group can reduce the cross-sectional diameter of the coil and reduce the distance between the chilled water at the axis of the coil and the refrigerant outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com