Liquid level sensor lever supporting structure

A technology of liquid level sensor and support structure, which is applied in the field of liquid level sensor and can solve the problems of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

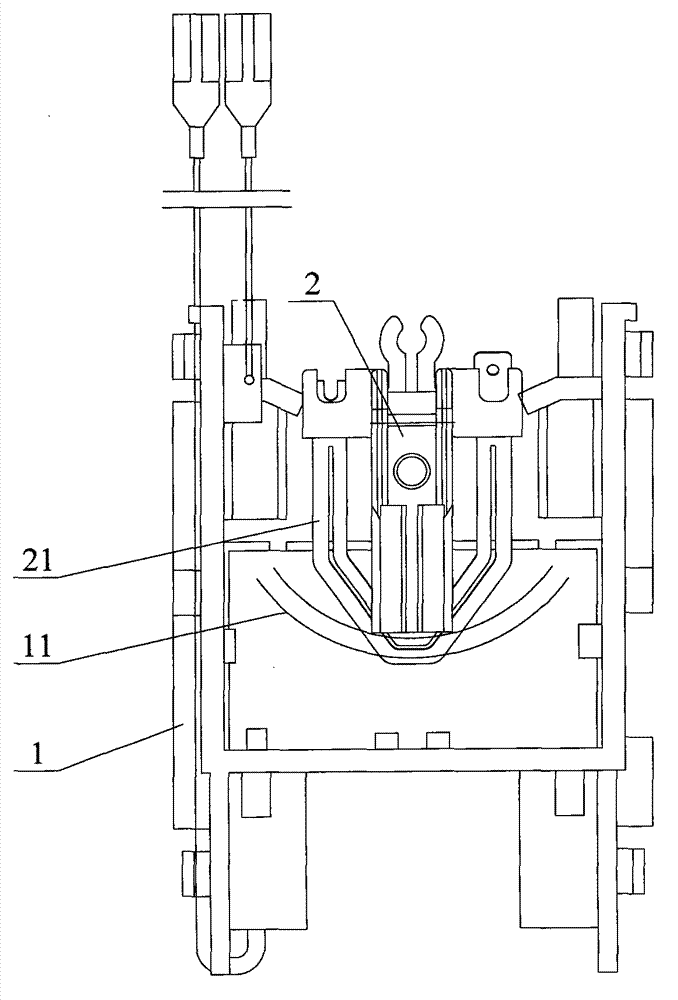

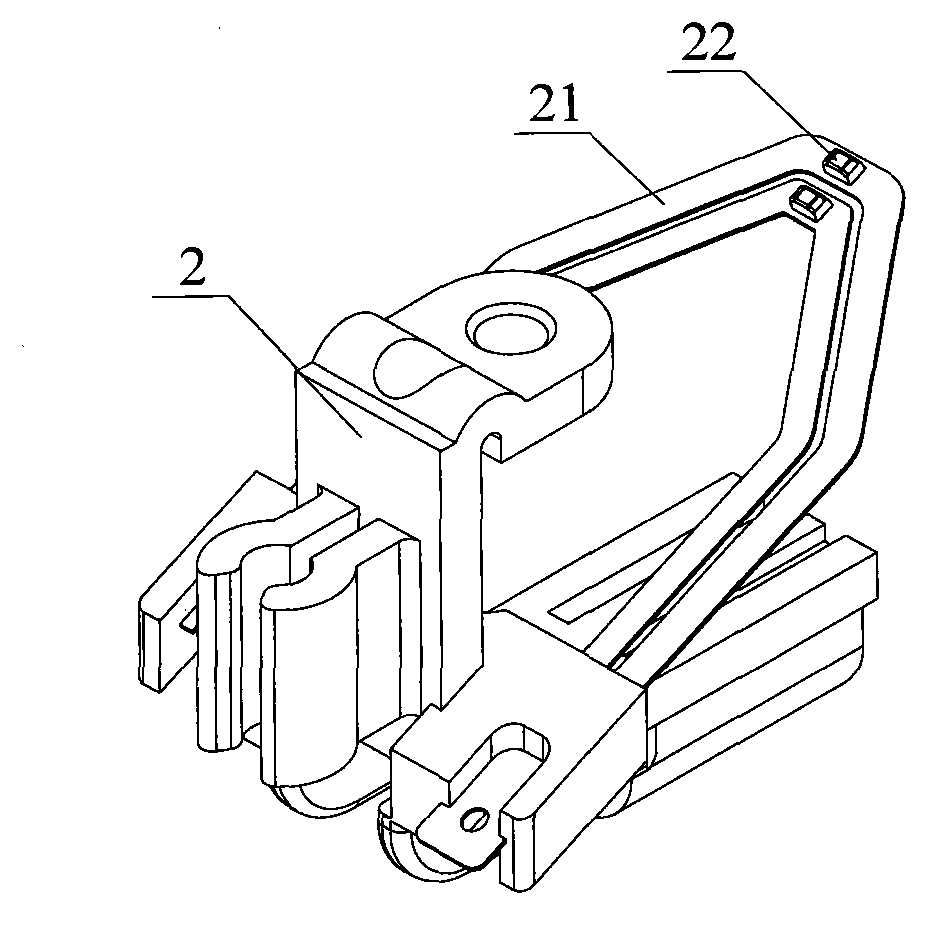

[0014] Such as Figure 1-2 As shown, a liquid level sensor lever support structure according to the embodiment of the present invention includes a lever support 2 and a skeleton 1, and a fan-shaped resistance sheet 11 is arranged on the skeleton 1, and the lever support 2 is installed on the skeleton 1 through a rotating shaft. Above, an inclined sliding piece 21 is installed on the lever support 2, and two columnar contacts 22 are arranged at the lower part of the front end of the sliding piece 21. The grinding layer is integrally formed between the noble metal wear-resistant layer and the columnar contact 22, and the columnar contact 22 is connected to the sliding piece 21 by die-casting.

[0015] The two cylindrical contacts 22 form a double-contact circuit with the sliding sheet 21 and the resistor sheet 11 .

[0016] The noble metal wear-resistant layer has an arc-shaped surface.

[0017] The noble metal wear-resistant layer adopts silver-palladium alloy.

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com