Catalyst coated membrane electrode of fuel cell with self-moistening function and preparation method thereof

A technology of catalyst coating and catalyst layer, which is applied in the direction of fuel cells, battery electrodes, fuel cell parts, etc., can solve the problems of increased manufacturing process and cost of membrane electrode assemblies, and achieves easy mass production, uniform thickness, enhanced The effect of water retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

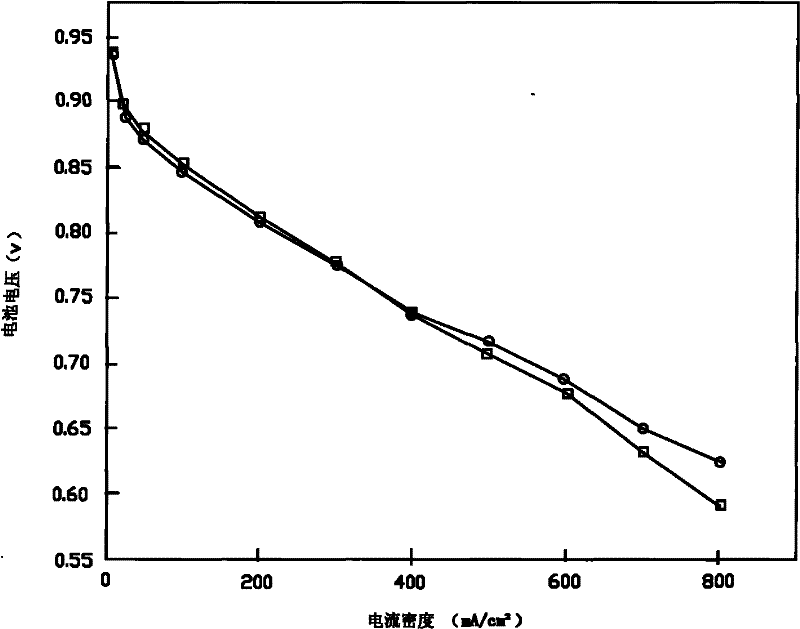

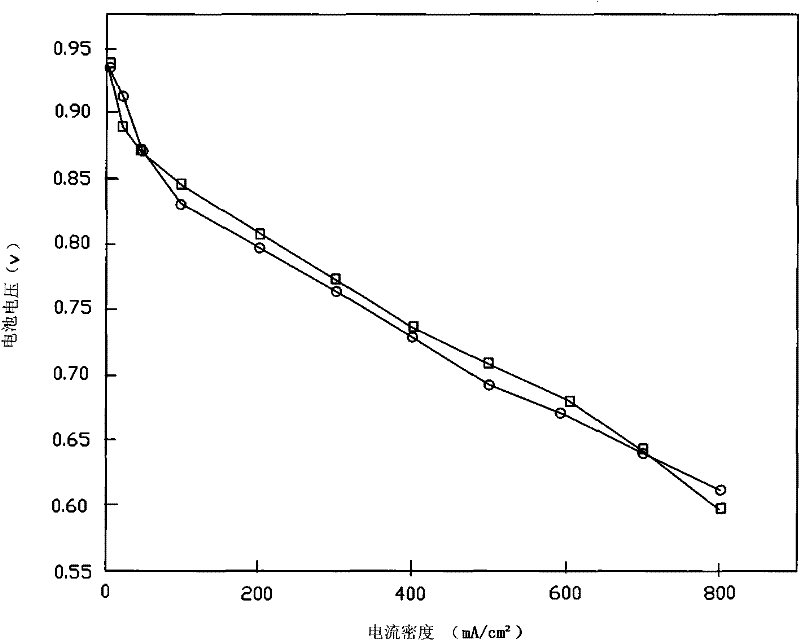

Image

Examples

Embodiment 1

[0019] 1) Preparation of inner catalyst layer electrode slurry. Weigh 21 mg of 50% wt.Pt / C catalyst, 210 mg of 5% Nafion solution, 10.5 mg of lithium carbonate, and 3.2 mg of fumed silica into a weighing bottle, and drop 5 drops of deionized water into the catalyst with a rubber dropper. Wet well, then add 5g of isopropanol. Place the weighing bottle in an ultrasonic generator and ultrasonically stir for 30 minutes, and set aside.

[0020] 2) Preparation of the electrode slurry for the outer catalyst layer. Weigh 21 mg of 50% wt.Pt / C catalyst, 140 mg of 5% Nafion solution, 10.5 mg of lithium carbonate, and 2 mg of fumed silica into a weighing bottle, and drop 5 drops of deionized water into the catalyst to fully Wet, and add 5 g of isopropanol. Place the weighing bottle in an ultrasonic generator and ultrasonically stir for 30 minutes, and set aside.

[0021]3) The effective spraying area is 34.3cm 2 The NRE211 film (6×14 cm in size) was fixed on the vacuum hot stage of t...

Embodiment 2

[0028] 1) Weigh 85 mg of Pt black catalyst, 850 mg of 5% Nafion solution, 42 mg of ammonium oxalate and 128 mg of 10% silica hydrosol into a weighing bottle, and then add 20 g of isopropanol. Place the weighing bottle in an ultrasonic generator and ultrasonically stir for 30 minutes, and set aside.

[0029] 2) Weigh 170 mg of 50% Pt / C catalyst, 1133 mg of 5% Nafion solution, 85 mg of ammonium oxalate and 170 mg of 10% silica hydrosol into a weighing bottle, and then add 40 g of isopropanol. Place the two weighing bottles in an ultrasonic generator and ultrasonically stir for 30 minutes, and set aside.

[0030] 3) Set the effective area to 283cm 2 The composite film (with a size of 10.1×41.2 cm) was fixed on the vacuum hot stage of the spraying machine, and the temperature of the hot stage was 140°C.

[0031] 4) Connect the electrode slurry prepared in step 1) to the pump, and connect the pump to the ultrasonic nozzle. Turn on the equipment and spray according to the program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com