Flexible and stretchable one-piece piezoelectric rubber and its preparation method

An all-in-one, piezoelectric technology for fabrication/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, material selection for piezoelectric or electrostrictive devices, etc. Direction, can solve the problems of poor stability performance, power generation cannot be clearly estimated, complicated production process, etc., and achieve the effect of low cost, good electrical signal output ability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

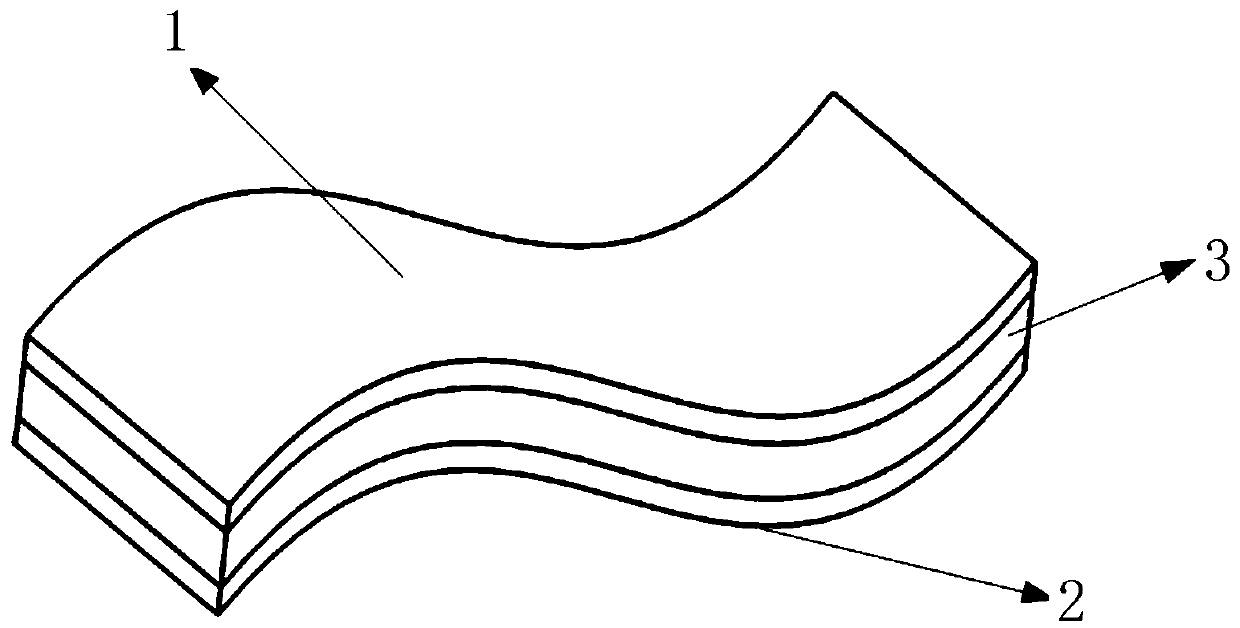

[0055] A flexible and stretchable one-piece piezoelectric rubber, including an electrode composite layer A, an electrode composite layer B and a piezoelectric composite layer. The specific preparation process is as follows:

[0056] Step 1. Preparation of stretchable insulating material

[0057] Proportion the mixed raw rubber and vulcanizing agent according to the ratio of 100:2, and knead on the mixer for 2 hours to make the mixed raw rubber and curing agent fully contact.

[0058] Step 2. Preparation of electrode composite layers A and B

[0059] Evenly mix the nano-conductive particles into the stretchable insulating material, the nano-conductive particles account for 60% of the total mass, knead on the mixer for 1 hour, and put the mixture into a steel plate grinding tool with a size of 50mm*50mm*1mm In the process, a flat vulcanization machine is used for vulcanization molding, the vulcanization temperature is 170°C, and the vulcanization time is 20 minutes.

[0060] S...

Embodiment 2

[0066] A flexible and stretchable one-piece piezoelectric rubber manufacturing method can also be prepared through the following steps:

[0067] Step 1. Preparation of stretchable insulating material

[0068] Proportion the mixed raw rubber and vulcanizing agent according to the ratio of 100:2, and knead on the mixer for 2 hours to make the mixed raw rubber and curing agent fully contact.

[0069] Step 2. Preparation of piezoelectric composite layer

[0070] Evenly mix the nano piezoelectric particles into the stretchable insulating material. The nano piezoelectric particles account for 70% of the total mass. After mixing on the mixer for 1 hour, put the mixture into a steel plate with a size of 50mm*50mm*1mm In the abrasive tool, use a flat vulcanization machine for vulcanization molding, the vulcanization temperature is 170 ° C, and the vulcanization time is 20 minutes.

[0071] Step 3, preparation of electrode composite layers A and B

[0072] Evenly mix the nano-conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com