Thermal power generating unit coal quantity feed-forward quantization design method based on coordination control qualities

A thermal power unit and design method technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as difficult coordination control system, coal quantity fluctuation, etc., to ensure the quality of coordination control, energy-saving operation, The effect of coal volume feed-forward fluctuation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] 1. Feed-forward quantitative scale of coal quantity

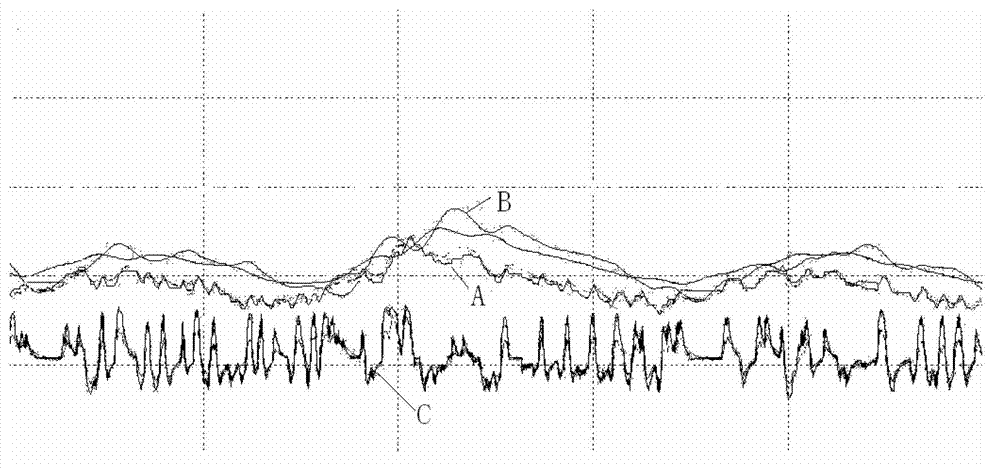

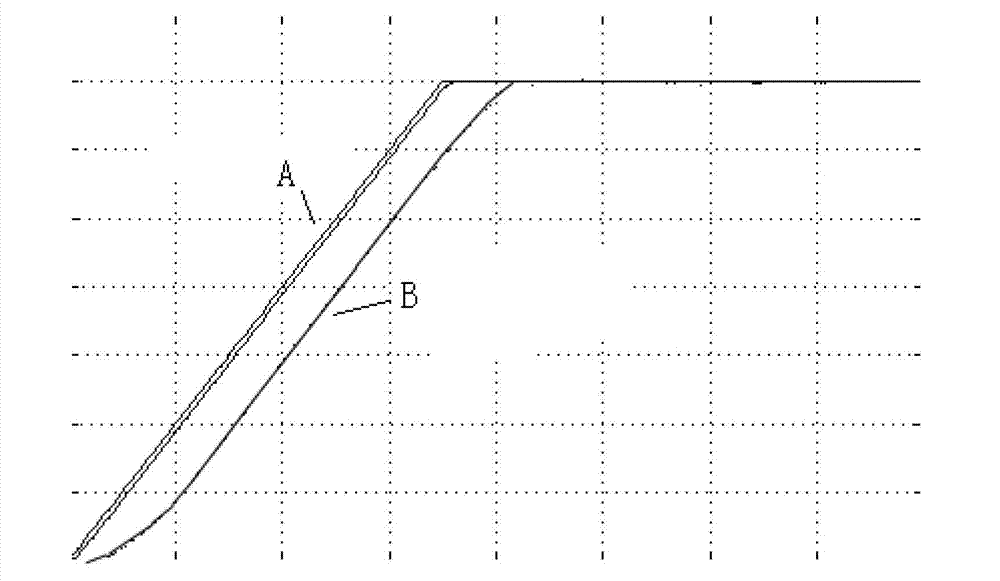

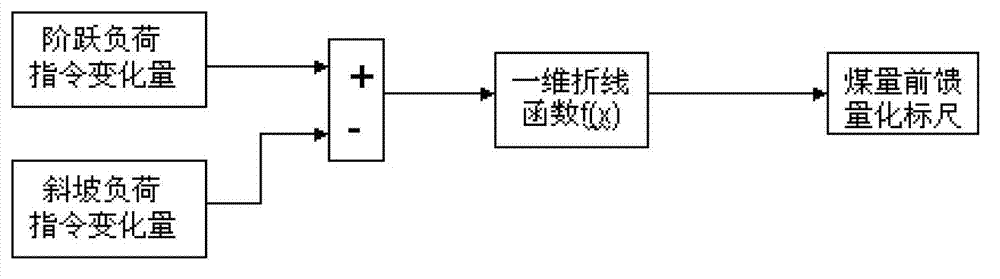

[0020] In order for the thermal power unit to respond quickly to the load, the size of the pre-supply coal amount (that is, the coal amount feedforward) needs to have a quantitative scale. Therefore, the coal quantity feed-forward quantitative scale is a tool to measure the quantitative conversion relationship between the load variation and the coal quantity variation. figure 1 The calculation steps of coal quantity feed-forward quantization scale are given.

[0021] exist figure 1 In , the variation of the load command and the variation of the coal quantity feed-forward are connected through a one-dimensional broken line function. The feed-forward quantitative scale of coal quantity is realized through load variation and one-dimensional broken line function. The basic values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com