Retractable multi-group longitudinal water seal photoelectric composite cable and manufacture process thereof

A photoelectric composite cable, retractable technology, applied in the direction of cable/conductor manufacturing, communication cables, cables, etc., can solve the problems of difficulty in construction and installation, dependence on imports, lack of longitudinal water sealing performance, etc., and achieve flexible and wear-resistant sheaths , satisfy the effect of high-end equipment, excellent photoelectric performance and mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

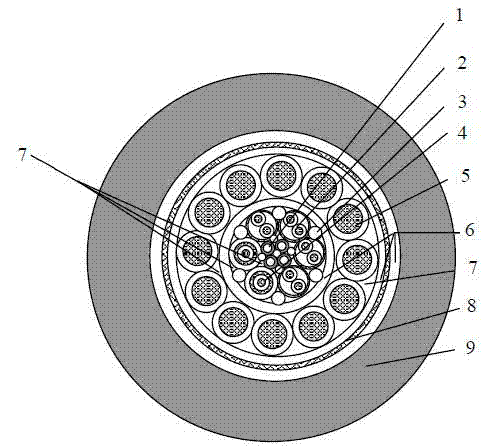

[0017] The retractable multi-group longitudinal water-sealed photoelectric composite cable and its preparation process combine signal lines for transmitting electrical signals, optical signals, and radio frequency signals, and power lines for transmitting electric energy into one cable.

[0018] The plurality of shielded twisted-pair wires 2 are water-blocking shielded twisted-pair wires, and an automatic and continuous glue injection process is adopted when the wire cores are twisted. The glue is filled into the gap between the paired wires through a glue injection mold, and wound Wrap the water blocking tape, then braid the shield.

[0019] The multiple tension-resistant aramid fiber filling ropes 3 are made of aramid fiber strands twisted into a rope with a certain size and outer diameter.

[0020] The coaxial cable 4 adopts a radio frequency coaxial cable with a single conductor structure.

[0021] The power cord 5 adopts regular stranded conductors. When the conductors a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com