Semiconductor device

A semiconductor and conductive terminal technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of approaching the limit, difficult to realize the miniaturization of semiconductor devices, electromagnetic interference, and low impedance at the same time. Achieving the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

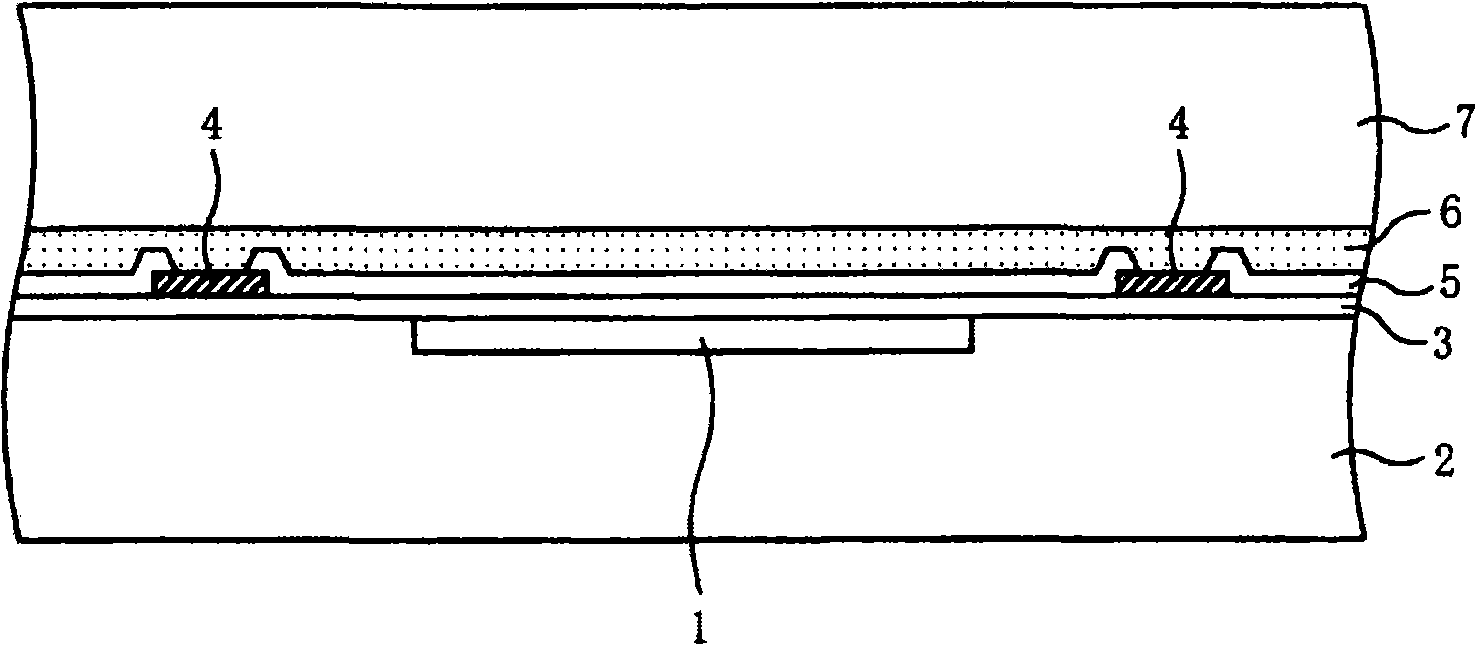

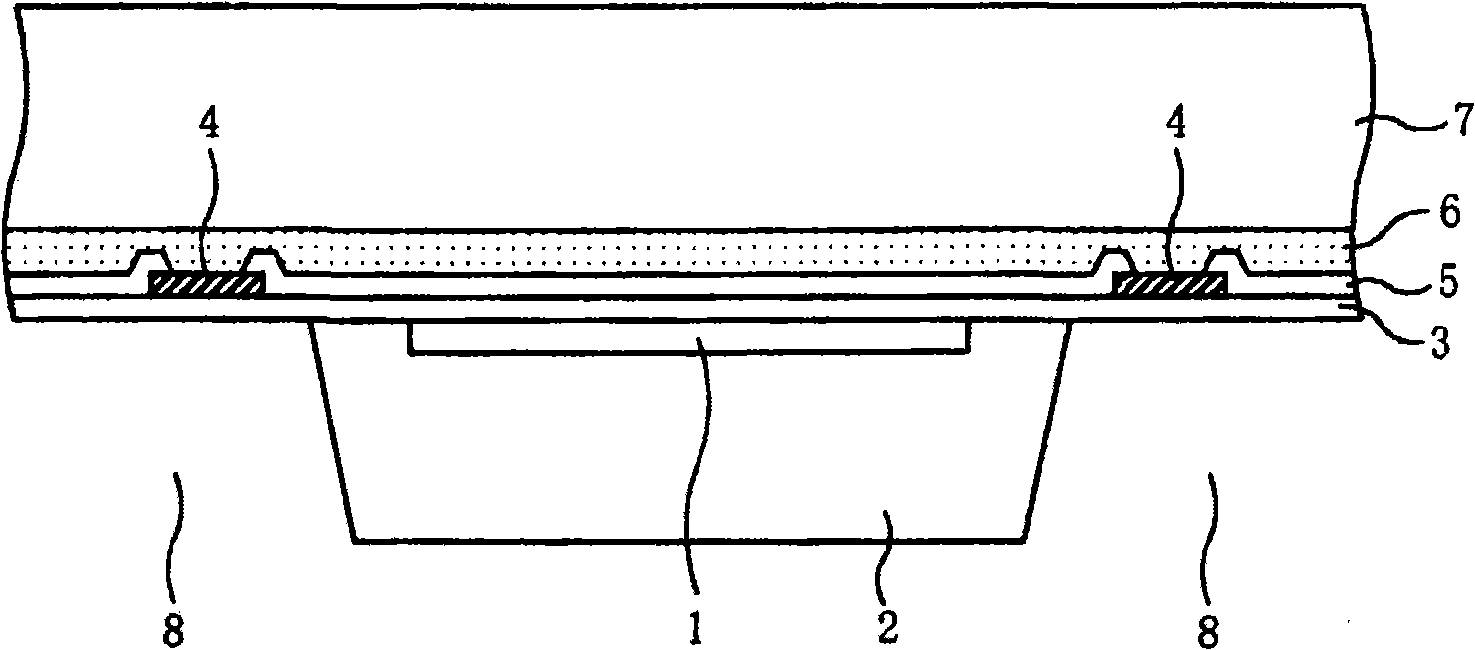

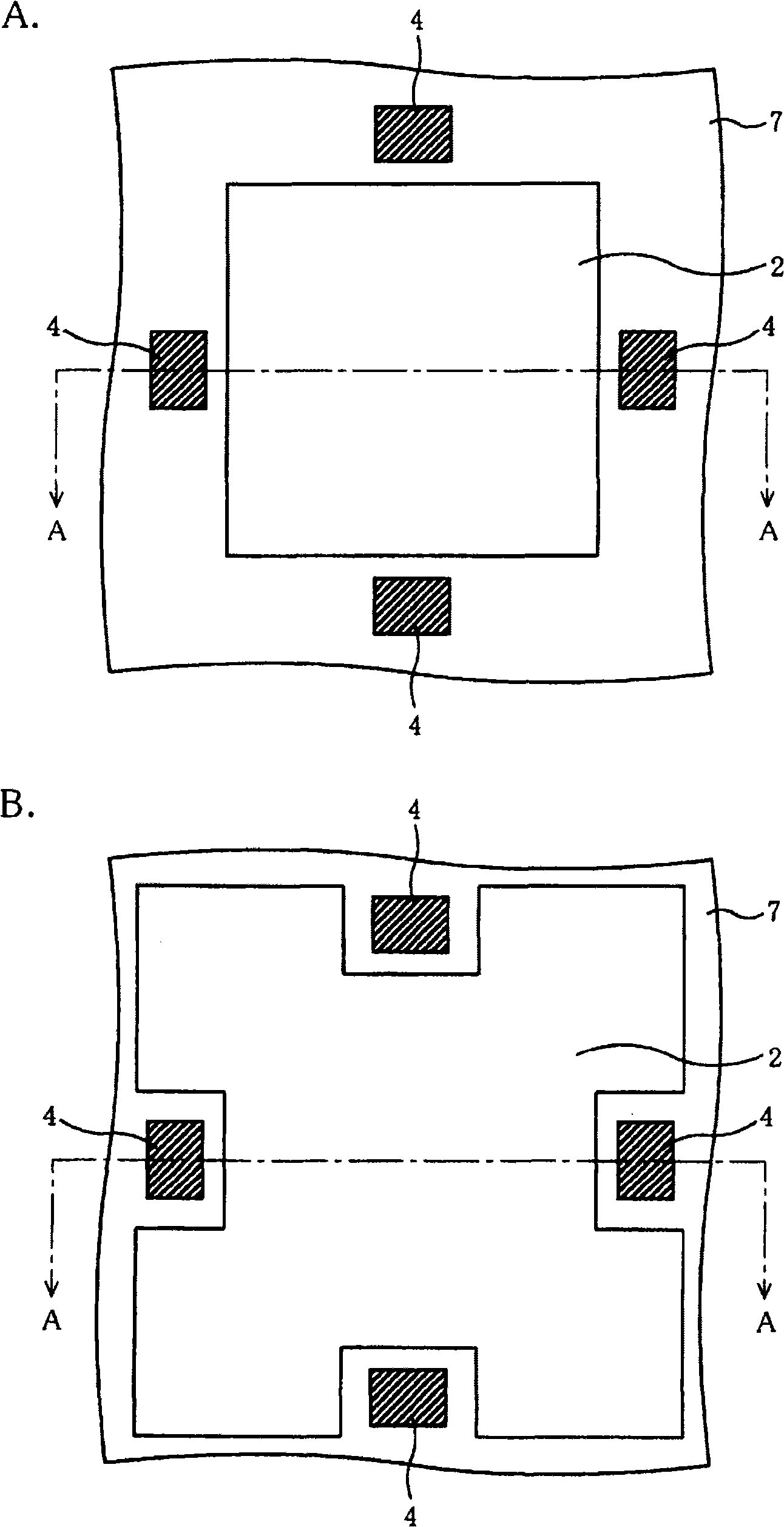

[0046] Next, a first embodiment of the present invention will be described with reference to the drawings. Figure 1 to Figure 9 A sectional view or a plan view showing the sequence of the manufacturing process, respectively. In addition, the manufacturing process described below is performed using a wafer-shaped semiconductor substrate, and a plurality of semiconductor devices are formed in an array with predetermined scribe lines as boundaries. For convenience, a process of forming one of the semiconductor devices will be described.

[0047] First, if figure 1 As shown, a semiconductor substrate 2 made of silicon (Si) or the like is prepared, and a semiconductor integrated circuit 1 (such as photosensitive elements such as CCD sensors, CMOS sensors, and illuminance sensors, light-emitting elements, and semiconductors such as transistors) is formed on the surface of the semiconductor substrate 2. A drive circuit, a logic circuit, or wiring connected to them, which are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com