Light emitting module assembly for radiator and lamp

A light-emitting module and heat sink technology, which is applied to semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, and can solve the problem of large amount of heat sink materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

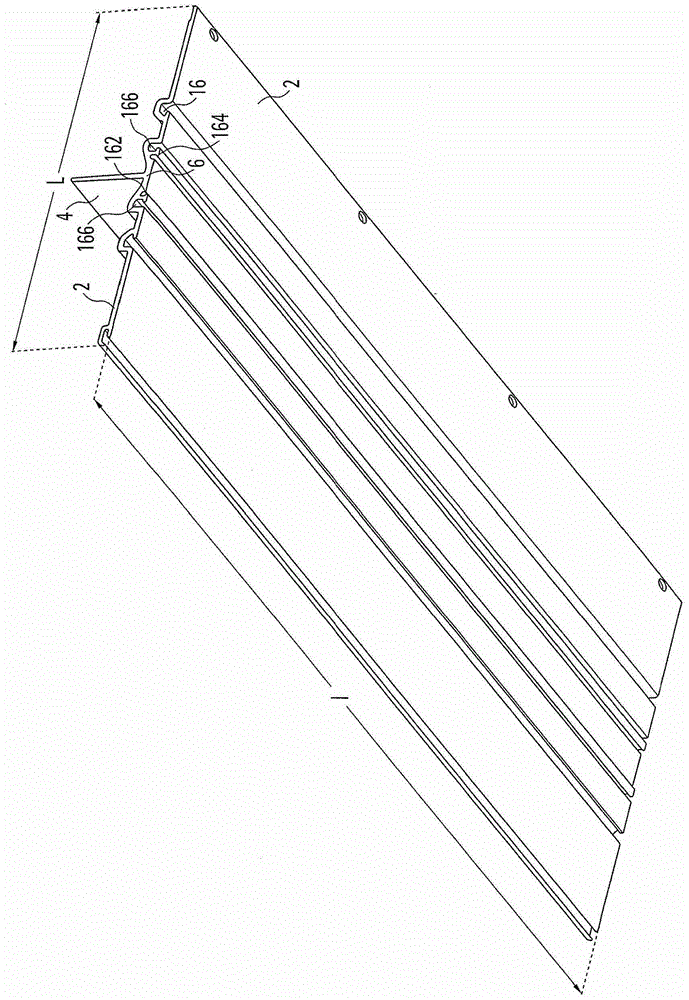

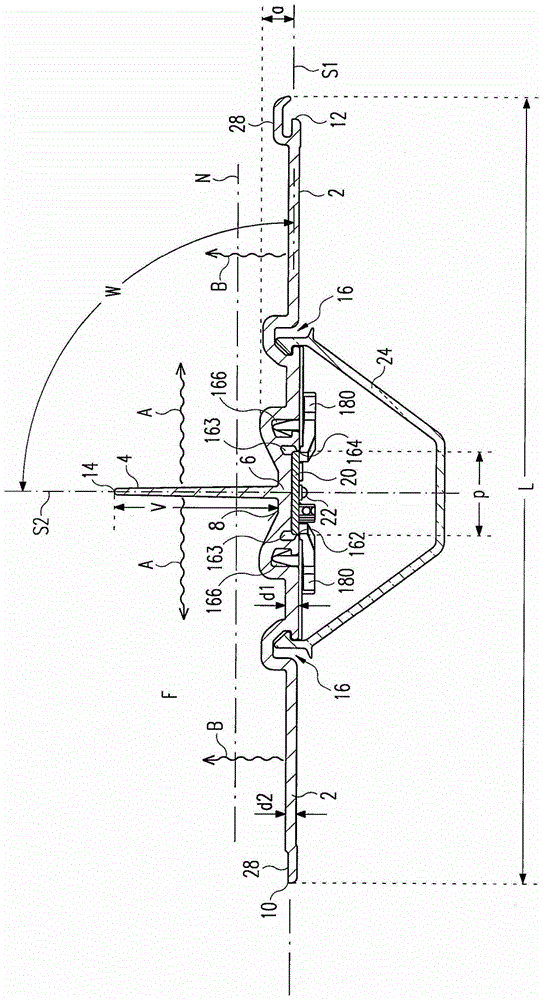

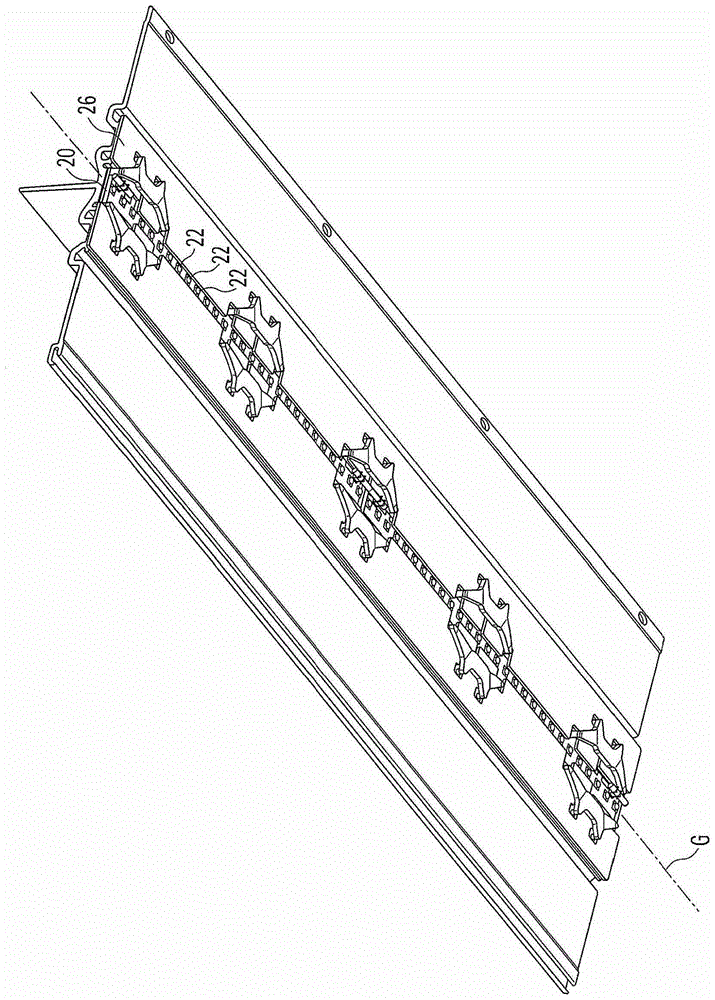

[0028] figure 1 A schematic perspective view of an embodiment of a heat sink according to the invention for a lamp is shown, figure 2 A corresponding cross-sectional view is shown. At this time, at figure 2 In addition to the heat sink, other components of the lamp that will be mentioned below are also shown.

[0029] The cooling body has an at least very approximately plate-shaped first section 2 and an at least very approximately plate-shaped second section 4 . "At least very approximately plate-shaped" here means that a plane is defined by the shape of the relevant segment and that the maximum distance of the surface of the segment from this plane is not greater than the smaller extent of the extent of the segment in that plane. Small percentages such as 10% or 5%. This will combine figure 2 Let's take an example to explain in detail. A plane S1 is defined by the plate-like structure of the first section 2 , which is referred to as the plane occupied by the largest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com