Chlorfenapyr and cartap granular preparation

A technology of cartap and chlorfenapyr, which is applied in the field of pesticide preparations, can solve the problems of easy resistance, adjuvants and unsatisfactory control effects, etc., and achieve the effects of low cost, increased insecticidal effect, and simple product process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

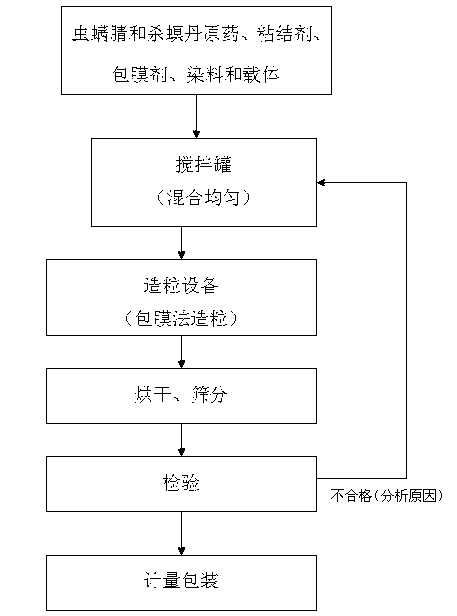

[0033] Embodiment 1: The preparation method of the chlorfenapyr and cartap granules of the present invention (technical scheme 1):

[0034] Based on the total weight of chlorfenapyr and cartap granules, of which: 0.5% of chlorfenapyr and 1.5% of cartap, 2% attapulgite, 0.15% of polyvinylpyrrolidone, 0.1% of reactive blue, and the balance of quartz sand .

[0035] Such as figure 1 As shown, according to the preparation method of granules of the present invention, the above-mentioned materials are uniformly mixed in a closed preparation kettle, granulated by coating method, dried at 120°C until the water content of the granules is 1%, and sieved, the particle size range is 4000 microns ( μm), after passing the inspection, 2% chlorfenapyr·cartap granules will be obtained.

Embodiment 2

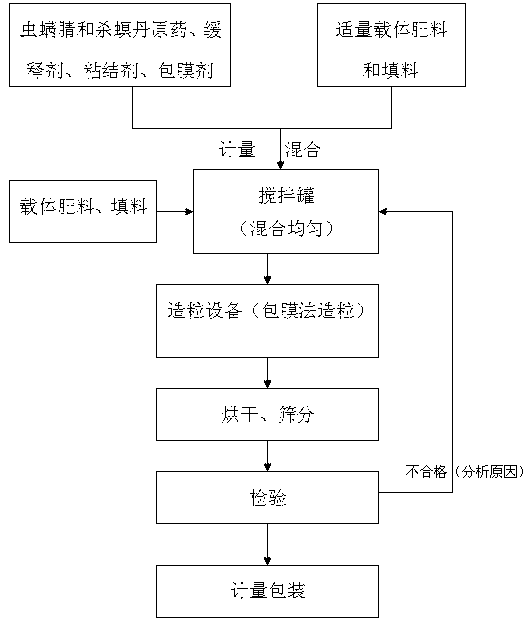

[0036] Example 2: The preparation method of chlorfenapyr and cartap granules (technical scheme two) of the present invention:

[0037] Based on the total weight of fungicide fertilizer granules, including: chlorfenapyr 0.01%, cartap 0.01%, carrier fertilizer 40%, slow-release agent 0.5%, binder 5%, coating agent 0.3%, and the rest is kaolin filler.

[0038] Such as figure 2 As shown, according to the granule preparation method of the present invention, 0.01% chlorfenapyr, 0.01% cartap, 40% carrier fertilizer, 0.5% slow-release agent, 5% binder, 0.3% coating agent, and an appropriate amount of filler are added to the After mixing evenly in a closed mixing tank, add it to the granulation equipment for coating granulation, dry at 80 ° C ~ 100 ° C until the water content of the particles is less than 3%, sieve (particle size range 2000um ~ 4000um), after inspection After passing the test, 0.02% chlorfenapyr·cartap granules will be obtained.

[0039] The production process of t...

Embodiment 3

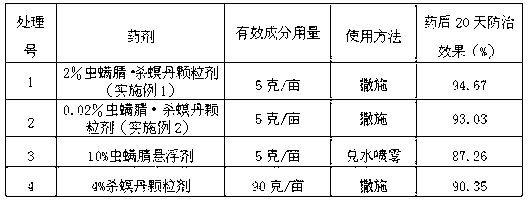

[0040] Embodiment 3: In order to better verify the actual application effect of the present invention, the following examples are used to illustrate the field drug efficacy test of the granules of the present invention. In June 2012, the inventor conducted an experiment on the control of rice leaf rollers in Huilong Village, Luming Town, Pingchang County, Bazhong City, Sichuan Province.

[0041] Drugs to be tested: (1) 2% chlorfenapyr·cartap granules (Example 1), (2) 0.02% chlorfenapyr·Cartap granules (Example 2).

[0042] Control agent: (3) 10% chlorfenapyr suspension concentrate, (4) 4% cartap granule.

[0043] Control object: Paddy rice leaf roller.

[0044] Test design.

[0045]

[0046] The test results show that the chlorfenapyr and cartap granules of the present invention have excellent control effects on rice leaf rollers, better than 10% chlorfenapyr EC and 4% cartap granules, and are safe for rice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com